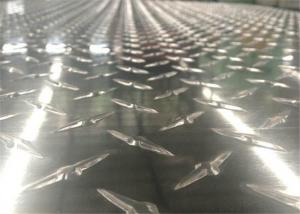

DC Aluminium Coil - Aluminum 4 X 8 Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard seaworthy export packing or as your request One 20'GP can load about 20 tons of aluminum sheets; one 40'GP can load about 24tons. |

| Delivery Detail: | About 20 days after receiving the prepayment or the original L/C |

Specifications

high quality hot rolled aluminium jumbo roll/coil prices 5052/5083/5754/5182

Strict quality control & competitive price

high quality hot rolled aluminium jumbo roll/coil prices/sheet price

Product Details:

Product Name | high quality hot rolled aluminium jumbo roll/coil prices/sheet price | |

Alloy No. | 5052/5083/5182/5752 | |

Temper | O, F, H12, H14, H16, H24, H26, H32, etc. | |

Thickness(mm) | 0.2 to 350 | |

Width(mm) | Up to 2280 | |

Length(mm) | Up to 12000 | |

MOQ | Normally 5 MT | |

Application | Cookware, Conductor, Decorations for Building, Vehicle & Ships, Instrument Board, Meter Housing, | |

Packing | Standard seaworthy export packing or as your request | |

Delivery Time | 10 to 20 days after receiving the prepayment or the original L/C | |

Terms of Payment | L/C at sight, L/L | |

Note | Specifications can be customized as the customer's requirements |

Packing Details:

1. Standard seaworthy export packing or as your request

2. One 20'GP can load about 20 tons of aluminum sheets; one 40'GP can load about 24tons.

Delivery Time:

10 to 20 days after receiving the prepayment or the original L/C

- Q: Where is the difference between the 5052 aluminum plate and the 1060 Aluminum plate?

- 5052 is aluminium magnesium alloy, 1060 is pure aluminium

- Q: Can aluminum sheet be used for electrical enclosures?

- Indeed, electrical enclosures can indeed utilize aluminum sheet. The remarkable conductivity, lightweight composition, and resistance to corrosion render aluminum a favored option for electrical enclosures. It effectively safeguards against electromagnetic interference and possesses commendable heat dissipation properties. Moreover, aluminum boasts malleability, enabling the production of intricate shapes and designs. In summary, aluminum sheet is a fitting material for electrical enclosures and finds widespread application in diverse industries like electronics, telecommunications, and power distribution.

- Q: What is the typical formability of aluminum sheets?

- The typical formability of aluminum sheets is high, as aluminum has excellent ductility and can be easily shaped into various forms without cracking or breaking.

- Q: Hello, I dont really know anything about using a drill or cutting through metal or wood. the thing is I have a project in which I have to drill some holes in 0.04in aluminum. but I really dont know if can use regular drill bits used for drilling wood to drill the holes in my aluminum chassis. do I need to buy other drill bits for cutting metal or can I use the same ones Ive seen used for cutting wood? can I even use the same kind of drills, or do I NEED a huge bench drill with stepper bits?thanks

- Aluminum is softer than steel, so you could just use the ordinary bits that you use for wood, with a hand drill. For cleaner holes, you might want to put wood behind the aluminum as a backing. Also, if you squirt a drop of oil onto the drill area, that will help. If you're trying to drill a really large hole, it might be better to drill small ones, and enlarge with a round file.

- Q: Are aluminum sheets resistant to corrosion?

- Indeed, corrosion is highly resisted by aluminum sheets. Upon exposure to air, aluminum creates a safeguarding oxide layer on its surface, effectively inhibiting any subsequent corrosion. This oxide layer serves as a shield, safeguarding the core metal against environmental elements, including moisture and corrosive substances. Furthermore, due to its minimal inclination to rust, aluminum is extensively favored in numerous domains where corrosion resistance is paramount, such as the fabrication of aircraft, automobiles, and marine vessels. In conclusion, aluminum sheets are renowned for their extraordinary ability to withstand corrosion, thereby enhancing their sturdiness and durability.

- Q: Can aluminum sheets be painted?

- Yes, aluminum sheets can be painted. However, it is important to properly prepare the surface by cleaning, sanding, and using a primer specifically formulated for metal surfaces to ensure good adhesion of the paint.

- Q: I put the aluminum in copper chloride for an experiment and i was wondering if they had different properites.

- Yes, Rust is an Oxide of iron which can be broken down chemically into simpler substances. Aluminium is a pure Element which cannot be broken down chemically or physically into other substances.

- Q: What is the typical fracture toughness of aluminum sheets?

- The fracture toughness of aluminum sheets can vary depending on several factors, such as the composition of the alloy, the heat treatment, and the manufacturing process. On average, the fracture toughness of aluminum sheets ranges from 20 to 40 MPa√m. This value reflects how well the material can resist crack propagation and withstand applied loads without breaking. It's important to note that the fracture toughness of aluminum alloys can be improved through techniques like adding alloying elements and refining the grain structure. Therefore, when considering the fracture toughness of aluminum sheets for a specific application, it's crucial to take into account the specific alloy and its processing conditions.

- Q: What are the different methods for cutting aluminum sheets?

- There are several methods for cutting aluminum sheets, including shearing, sawing, laser cutting, waterjet cutting, and plasma cutting.

- Q: Are aluminum sheets suitable for electronic enclosures?

- Yes, aluminum sheets are suitable for electronic enclosures. Aluminum is a lightweight and durable material that offers excellent conductivity and thermal management properties, making it ideal for electronic enclosures. It also provides good shielding against electromagnetic interference (EMI) and offers corrosion resistance, making it a popular choice in the electronics industry.

Send your message to us

DC Aluminium Coil - Aluminum 4 X 8 Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords