DC/AC Solar Water Submersible Pumps SHP/SPA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 400 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

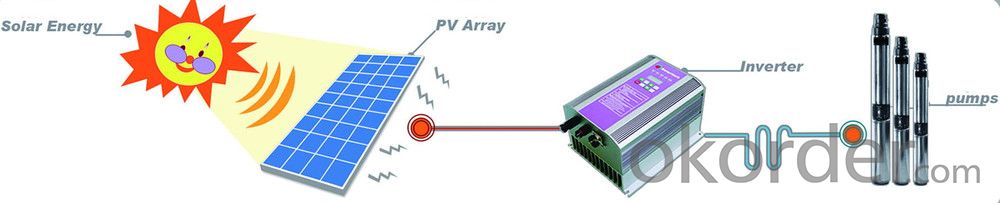

1. Solar Water Pumping System Introduction

1,Solar Cell Array

The solar array, an aggregation of many solar modules connected in series and in parallel, absorbs sunlight radiation and converts it into electrical energy, providing dynamical power for the whole system.

2,Solar Pumping Inverter

The pumping inverter controls and adjusts the system operation and converts the DC produced by the solar cell array into AC to drive the pump, and adjusts the output frequency in real-time according to the variation of sunlight intensity to realize the maximum power point tracking (MPPT). Advantages are as follows:

1). Patented dynamic VI MPPT algorithm ensuring swift response and stable operation

2). Digital control, automatic operation, data collection and storage for up to 8 years, etc; 98% conversion efficiency, complete protection

3). The system is free of any energy storage devices. Instead, the system stores water. As a result, reliability is improved dramatically comparing to systems requiring energy storage (battery) and at the same time greatly reducing construction and maintenance costs

3,Pump

Any three-phase pump is suitable for solar AC pumping system, pump powered by solar cell arrays draws water from the deep wells or rivers and lakes and pours into the storage tank or reservoir, or directly connects the irrigation system, fountain system, etc. According to the actual system demand and installation condition, different types of pumps such as centrifugal pump, axial flow pump, mixed flow pump or deep well pump can be used.

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- For the first time, the pump and motor were placed on the base and not fastened (Cu Zhaozheng);Second times, the pump and motor have been tightened, the inlet and outlet flange bolts are not fastened;Third times, the pump runs 24 hours later.

- Q: How about the depreciation of vacuum pumps?

- (five) electronic equipment, for 3 years.The depreciation period of a vacuum pump can be calculated for 5 years. The expected residual rate is generally 5%, or it can be estimated by itself.

- Q: 5 floor water pressure is too low, what kind of water pump is better?

- The location of the pump is too far away from the pumping pool, the suction of the pump is not enough, cavitation phenomenon, pumping water, this water pump manufacturers, the pump will be placed in a reasonable position

- Q: What are the characteristics of a pipe shield pump?

- Two, reverse circulation type of shielding pump, its bearings, lubrication, cooling and motor cooling fluid flow direction and the basic type is the opposite. The main characteristic of reverse circulation pump is that it is not easy to generate cavitation. It is suitable for conveying liquid which is easy to vaporize. Sometimes it is also called "easy to vaporize" type. Three, high temperature medium temperature of up to 450 degrees. The cooling water jacket is usually added outside the shielding motor, and a cooling sleeve is added to the outer circulation pipe to cool the high temperature circulating liquid to reduce the temperature of the motor and the bearing. In the case of less power, some manufacturers do not use cooling liquid, but the outside of the motor is equipped with fins and the special winding to adapt to the working conditions, the use of temperature generally can not exceed 400 degrees.

- Q: I live on the 8 floor. Often there is no water. Life is very inconvenient. What kind of pump do I have to install? What should I pay attention to when I buy it? What's the pump for that brand? Should it be installed in that position?

- Installation method of hydraulic pump(1) according to the technological requirements and the cavitation conditions of the pump, the installation height check and the civil engineering of the foundation are carried out.(2) prepare a series of flat washers and wedge gaskets of different thickness before installation.(3) according to the characteristics of the pump conveying medium, determine the material of the gasket at the connection and process the gasket.

- Q: What is the function of the heating pump system for the water pump design?

- As the feed water temperature is higher, before starting, if not enough to warm the pump, the pump body temperature is uneven, there is a hot, cool phenomenon. The upper part is inflated and the lower part is inflated"

- Q: Centrifugal pump flow, why can be adjusted through the outlet valve? Can the flow of the reciprocating pump be adjusted in the same way?. Why

- Reciprocating pump is a positive displacement pump, the volume change of flow is the unit of time, constant flow speed constant, can not rely on increased resistance to change the flow resistance increase is only leaked, only small changes in flow.

- Q: What are the differences between the sewage pump and the clean water pump?

- 2. in order to prevent the wound, water pump impeller design is more simple but not ring pump, equipped with tips, cloth and other debris can be crushed after the pump, and the impeller water pump is relatively complex, but the efficiency will be significantly higher than the former.Why can't the sewage water pump and impeller: because features of key design, resulting in water pump for sewage situation is likely to occur, blocking, winding, wear and corrosion occurs, resulting in damage to pump or scrapped, so water pump can not be used for sewage.

- Q: What is the series of pumps? What is the difference between a unipolar and a multilevel? What is the meaning of each "first class"?

- Each impeller is of the first stage. (two impellers share only one level, and exit is only level one)

- Q: Why adjust the centrifugal pump outlet valve can adjust the flow? What are the advantages and disadvantages of this method? Is there any other way to regulate the flow of the pump?

- This method can be used to regulate flow. The advantage is that it is simple and easy to use and the disadvantage is that the throttle consumes energy

Send your message to us

DC/AC Solar Water Submersible Pumps SHP/SPA

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 400 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords