Dark Bronze Anodized Aluminum Sheets - Coated Aluminium Sheets According to RAL No. from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

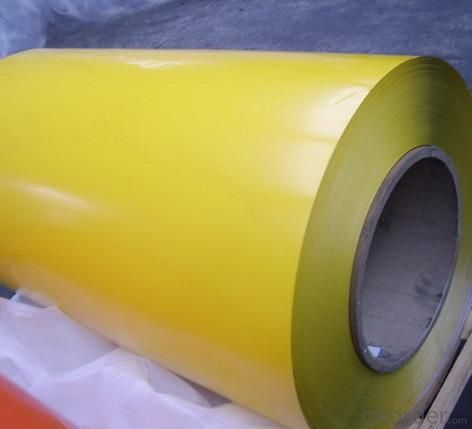

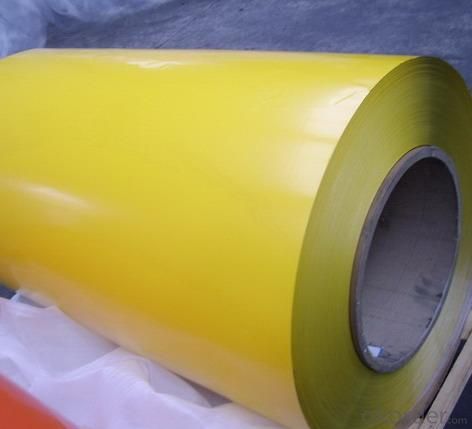

CNBM colour coated aluminium sheet

Colored aluminum foil rolls are widely applied to aluminum ceiling, roofing, fireproof roller shutter, doors, wall panel , facade cladding, etc.

1. Specification for coated aluminum coils

01)Material: aluminum alloy A1100, A3003, A3005, A3105

02)Aluminum thickness:0.20-1.20mm

03)Max coil width: 1600mm(standard 12 40mm)

04)Coil's standard diameter:1200mm, Interior diameter: 405mm,505mm, etc.

05) weight: 0.5-3.0T/coil or by buyer's option

06) Surface treatment: PE or PVDF coating

07) Color: solid, metallic, glossy, matte, wooden grain, marble stone,etc.

08) Dried and baked: oven baked at 450 degree F

09) Coating thickness: PVDF-25 micron, PE-18 micron

10) Coating hardness: (pencil hardness) HB

11) Coating adhesive: no lower than first grade

12) Impact resistance: no cracking and peeling(50kg/cm, ASTMD-2794:1993)

13)Flexibility(T-bend):2T or by your option

14) MEK resistance: more than 100

15)Outer packing: wooden plate, covering with craft paper and film, Eye to Sky or wall to Sky packing.

2. Applications

Interior applications:wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

Exterior applications: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

Advertisement and market applications: display platforms, signboards, fascia, shop fronts...

Packaging & Delivery

| Packaging Details: | Covering the coil with craft paper and films, and packed with wooden pallets. |

| Delivery Detail: | 10-15 days after getting deposit |

- Q: Are aluminum sheets suitable for electrical busbars?

- Yes, aluminum sheets can be suitable for electrical busbars. Aluminum is a widely used material in the electrical industry due to its excellent electrical conductivity, lightweight nature, and affordability compared to other metals like copper. Aluminum sheets can be easily fabricated into the desired shape and size required for busbars, making them a versatile choice for electrical applications. Additionally, aluminum has good thermal conductivity, which helps in dissipating heat generated during electrical operations. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so it may require larger cross-sectional areas to achieve the same electrical performance. It is essential to consider the specific requirements of the electrical system and consult with experts to determine if aluminum sheets are suitable for a particular busbar application.

- Q: Explain the impact of aluminum sheets on the thermal insulation of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can significantly reduce the thermal insulation of a building. They allow heat to transfer easily through them, which can lead to increased heat loss in winter and heat gain in summer. This can result in higher energy consumption for heating and cooling, making the building less energy-efficient. However, when used in combination with proper insulation materials and techniques, aluminum sheets can still be part of an effective building envelope, provided their thermal bridging effects are mitigated.</p>

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: Is it suitable to use aluminum sheets in environments with high moisture levels?

- <p>Yes, aluminum sheets can be used in areas with high humidity. Aluminum is a corrosion-resistant metal that does not rust, making it suitable for humid environments. However, it's important to ensure that the aluminum is properly coated or anodized to protect it from potential damage due to moisture. This treatment can prevent any form of corrosion and extend the life of the aluminum sheets.</p>

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: How to clean the aluminium oxide on the surface of aluminum? What kind of materials should we use to clean the thin aluminum sheet, and what's the concentration?

- you can answer sodium hydroxide solution, dilute acid is useless, aluminum's oxide film is very thick,as for concentration, aluminum will be passivating in concentrated sulfuric acid. if you are high school student,higher concentration is better, you can complete deoxidation by abrasive paper.

- Q: Can aluminum sheets be used for automotive heat shields?

- Yes, aluminum sheets can be used for automotive heat shields. Aluminum is a lightweight and highly heat-resistant material, making it suitable for shielding the vehicle's components from excessive heat generated by the engine or exhaust system. Its high thermal conductivity helps dissipate heat effectively, making it a popular choice for automotive heat shields.

- Q: Are aluminum sheets suitable for electrical connectors?

- Yes, aluminum sheets are suitable for electrical connectors due to their excellent electrical conductivity and corrosion resistance.

- Q: Can aluminum sheets be etched or engraved?

- Indeed, it is possible to etch or engrave aluminum sheets. The process entails removing a portion of the material from the surface by utilizing acid or a laser with substantial power. This technique allows for the creation of detailed designs, patterns, or even textual elements on the aluminum sheet. The applications for etching or engraving are diverse, including signage, decorative items, and industrial components. To achieve the desired appearance, color or other finishes can be added to further enhance the resulting design on the aluminum sheet.

- Q: What are the different manufacturing methods for aluminum sheets?

- Aluminum sheets can be manufactured using various methods, each possessing its own unique characteristics and applications. 1. Rolling, the most commonly employed method, involves passing large aluminum slabs through a series of rollers to reduce thickness and increase length. This process ensures consistent thickness and excellent surface finish. 2. Another method, extrusion, utilizes a heated aluminum billet forced through a die, resulting in a continuous sheet. Extrusion allows for the creation of complex shapes and profiles, making it suitable for applications in building construction and automotive components. 3. Casting involves pouring molten aluminum into a mold, allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or those with specific alloy compositions. Casting offers unique properties and is prevalent in industries such as aerospace and defense. 4. Cladding entails bonding a thin layer of aluminum to another material like steel or composite materials. This combines the desirable qualities of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets find common use in construction, transportation, and electrical industries. 5. Powder metallurgy involves forming aluminum sheets from powdered aluminum particles. The powder is compacted into the desired shape and then sintered at high temperatures to fuse the particles together. This method is ideal for producing complex shapes and can improve mechanical properties. Considering the desired properties, application, and cost considerations, it is crucial to select the most appropriate manufacturing method for aluminum sheets based on the specific project requirements.

Send your message to us

Dark Bronze Anodized Aluminum Sheets - Coated Aluminium Sheets According to RAL No. from China

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords