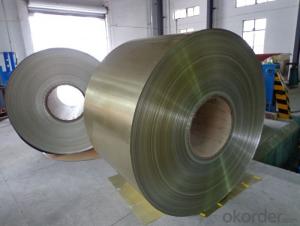

Customized Coated Aluminum Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum plate/sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: What are the necessary safety measures one should take while using aluminum coils in a kitchen setting?

- <p>When using aluminum coil in a kitchen, safety precautions include: 1) Ensuring proper ventilation to avoid inhaling fumes, as aluminum dust can be harmful. 2) Wearing protective gear such as gloves and goggles to protect your skin and eyes from potential contact with aluminum or sharp edges. 3) Handling the aluminum coil carefully to prevent cuts or injuries. 4) Avoiding contact with acidic or alkaline substances, as aluminum can react with them. 5) Not using aluminum coil near open flames or high heat sources, as it can melt or cause fires. 6) Cleaning up any aluminum dust or debris promptly to prevent slipping hazards. 7) Storing aluminum coils in a dry, cool place away from chemicals and heat sources.</p>

- Q: Is it possible to construct a portable speaker or speaker docking station using aluminum coils?

- <p>Yes, you can use aluminum coils in the construction of a portable speaker or speaker docking station, but they are not the primary component. Aluminum coils can be used in the speaker's electromagnetic parts, such as in the voice coil of the speaker driver or in the transformer of a docking station. However, the main components of a speaker include a diaphragm, voice coil, magnet, and enclosure, while a docking station would require a connector for the device, an amplifier, and possibly additional circuitry. The aluminum coil's role is to facilitate the magnetic field interaction with the voice coil, which converts electrical signals into sound waves. It's essential to consider the entire design and other necessary components when building such devices.</p>

- Q: Can aluminum coils be used in the production of beverage cans?

- Yes, aluminum coils can be used in the production of beverage cans. Aluminum is a preferred material for the manufacturing of beverage cans due to its lightweight, durability, and ability to preserve the taste and quality of the contents. Coils made of aluminum are typically used in the canning process as they can be easily shaped into a can form. The coils are rolled into sheets, which are then cut and formed into cans. Aluminum coils also have excellent heat conductivity, allowing for efficient cooling and faster production speeds. Overall, aluminum coils are an essential component in the production of beverage cans and are widely used in the industry.

- Q: This question asks for an explanation of the various materials used for coating aluminum coils.

- <p>Aluminum coil coating materials can be categorized into several types, including: 1. Organic coatings, such as polyester, acrylic, and polyvinylidene fluoride (PVDF), which offer good weather resistance and color stability. 2. Inorganic coatings, like fluoropolymers, which provide exceptional chemical resistance and high-temperature stability. 3. Metal coatings, such as zinc or other metals, used for enhanced corrosion resistance. 4. Ceramic coatings, which are known for their high durability and resistance to heat and chemicals. 5. Laminates, which combine multiple materials for specific performance characteristics. These coatings are chosen based on the intended application of the aluminum coil, such as in construction, automotive, or packaging industries.</p>

- Q: How do aluminum coils perform in cryogenic environments?

- Due to their low thermal expansion coefficient and high thermal conductivity, aluminum coils have excellent performance in cryogenic environments. When subjected to extremely low temperatures, aluminum coils display minimal contraction and expansion, making them suitable for cryogenic applications. The coils' low thermal expansion coefficient ensures that they maintain their structural integrity and do not deform or crack when exposed to extreme temperature fluctuations. Moreover, aluminum's high thermal conductivity facilitates efficient heat transfer, enabling the coils to effectively dissipate excess heat and maintain a stable temperature in the cryogenic environment. All in all, aluminum coils are a dependable choice for use in cryogenic environments and can effectively withstand the challenges presented by extremely low temperatures.

- Q: Can the 5-10cm thick paper sleeve inside the scrapped aluminum coil be sliced? Now we use knife which is much troublesome.

- You can use Long Men Rolling Mill to slice directly.

- Q: Can aluminum coils be used in the production of aluminum honeycomb panels?

- Aluminum honeycomb panels can indeed incorporate aluminum coils in their production process. To create these panels, aluminum sheets are affixed to a honeycomb core material, typically composed of aluminum as well. The aluminum coils are commonly employed to manufacture the aluminum sheets forming the panels' outer layer. After being rolled into thin sheets, these coils are cut to the desired dimensions and subsequently bonded to the honeycomb core. The utilization of aluminum coils enables the efficient and cost-effective manufacture of aluminum honeycomb panels, as they can be easily molded and processed to meet the necessary shape and size requirements. Moreover, aluminum possesses the qualities of being lightweight and durable, rendering it an optimal selection for fabricating honeycomb panels utilized in diverse industries, including aerospace, construction, and transportation.

- Q: What are the different coil coating options for aluminum coils?

- There are several coil coating options available for aluminum coils, including polyester, polyurethane, fluoropolymer, and plastisol coatings. Each option offers unique benefits, such as durability, weather resistance, and aesthetics, allowing for customization based on specific requirements or desired appearance.

- Q: Can aluminum coils be used for industrial piping?

- Industrial piping can indeed utilize aluminum coils. Aluminum, being a versatile and lightweight material, presents numerous advantages for industrial piping purposes. Its exceptional resistance to corrosion makes it a suitable choice across various industries such as chemical, petrochemical, and food processing. Moreover, aluminum coils are effortlessly manageable and can be molded into diverse configurations and dimensions, providing flexibility when designing and installing piping systems. Furthermore, aluminum's commendable thermal conductivity proves advantageous for applications that necessitate heat transfer. Nevertheless, it is crucial to carefully contemplate the specific requirements of the industrial process and seek advice from professionals to guarantee that aluminum coils are appropriate for the intended application.

- Q: How are aluminum coils processed for surface preparation?

- Aluminum coils are processed for surface preparation through a series of steps. Firstly, they undergo degreasing to remove any dirt, oil, or grease from the surface. This is followed by etching, where the coils are treated with an acidic solution to remove any impurities and provide a clean surface for coating. Next, the coils are rinsed and dried to ensure a residue-free surface. Finally, a conversion coating process is applied to enhance corrosion resistance and promote adhesion of subsequent coatings.

Send your message to us

Customized Coated Aluminum Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords