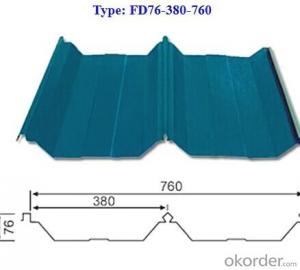

Currugated Color or Galvanized Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Product name | Prepainted galvanized corrugated steel sheet |

Length | As your requirement |

Width | 40mm-1250mm or as your requirement |

Thickness | 0.2mm-2mm |

Color | Ral NO. |

Coil weight | 3-8tons |

Zinc coating | 40-275g/m2 |

Quality standard | JIS G3002 , JIS G3312 |

Lacquer | According to your needs |

Term | FOB,CFR,CIF |

Coil ID | 508mm,610mm |

Top coating | 15-25microns |

Back coating | 5-10microns |

MOQ | 50 tons |

Base material | Hot dipped galvanized steel coil |

Packaging Detail | 1.Coil then to be properly wrapped with water proof /resistant paper, it then to be properly and completely metal wrapped. 2.Wooden and iron pallet can be used or as your requirements. 3.And each packed coil to be properly wrapped with band, three-six such band through the eye of coil at about equal distance, and two-four such bands securely tied around belly of coil at about equal distance |

Delivery Detail | 40 days |

advantages

1.We had already passed the authentification by the ISO9001 and established a completed set of quality assurace system.

2.Under such a complete set of quality assurance systems,there is a complete set of regulations for ordering,order handing,quality design,purchasing raw materials,working ot production plan,prodction,test and inspection,packaging,storage,delivering,etc.

3.The PC-based production and marketing system not only improves the working efficiency but also ensres the quality of product.

4.Our PPGI lines are equipped with a large amount of online test instruments so that they can ensure and improve the quality of product.

- Q: How do steel coils impact the environment?

- Steel coils impact the environment in several ways. Firstly, the production of steel coils requires large amounts of energy and resources, leading to increased greenhouse gas emissions and depletion of natural resources. Additionally, the manufacturing process generates air and water pollution, contributing to environmental degradation. Furthermore, the disposal of steel coils after use can result in land pollution if not properly managed. Overall, the production and use of steel coils have a significant environmental footprint.

- Q: I'm sort of a sword maker. You could say I'm an amateur blacksmith. I want to find a dependable source of high-grade steel. I've made a few blades and from what I know about the difference between true steel and cheap steel, I have yet to work with such. All of the metal I have used could not have been true high carbon spring steel because while they are hard, their properties do not reflect that of true steel. I would sincerely appreciate any guidance on where I could order some fine-quality steel so I could produce a truly fine blade.

- The phrase true steel has no technical meaning. Steel comes in many alloys and grades. Sorry I have no idea where to get different grades and types of steel. McMaster Carr carries a lot of steel bars, sheets, etc.

- Q: How is the critical temperature of structural steel affected by fireproofing? What temperatures can fireproofed structural steel withstand?

- mix the fire retardant with cement, let it harden fast to superstructure. this will create better stability and will not be dislodged in case of impact.

- Q: How are steel coils protected against moisture and humidity?

- Steel coils are protected against moisture and humidity through a variety of methods. One common method is the application of a protective coating on the surface of the steel. This coating acts as a barrier, preventing moisture from coming into direct contact with the steel surface. Coatings can be made of various materials such as paint, zinc, or other corrosion-resistant substances. In addition to coatings, steel coils are often wrapped in a moisture-resistant material such as plastic or waxed paper. This wrapping provides an extra layer of protection, preventing moisture from seeping into the coils during storage or transportation. Furthermore, steel coils are typically stored in a controlled environment with controlled humidity levels. This helps to minimize the chances of moisture condensation on the surface of the coils. Storage facilities may also utilize dehumidifiers or other moisture control measures to maintain optimal conditions. Lastly, proper handling and transportation practices are crucial in ensuring the protection of steel coils against moisture and humidity. Special care is taken to avoid exposing the coils to rain or excessive humidity during loading, unloading, and transportation processes. By employing these various protective measures, steel coils can be effectively safeguarded against moisture and humidity, reducing the risk of corrosion and maintaining their quality and integrity.

- Q: I understand that Stainless Steel is a low carbon steel having minimum 10.5% chromium content in it there r 60 different type of stainless steel. Kindly informa) Is this info correct?????b) Which stainless steel can get rusted or can have superficial rust????

- Stainless steel is a generic term for a whole range (there are more than 60 types) of Fe-Cr alloys. They all contain some amount of C and some alloys include a good number of other alloying elements. In almost all cases, the materials have corrosion resistance due the Cr atoms that are in solid solution with the Fe matrix. Under corrosive conditions, the Cr forms a thin tight coherent layer of Cr-oxide. This Cr oxide coating prevents further corrosion so long as it is not chemically or physically removed. If the SS has been subject to mechanical abrasion, the corrosion resistance can sometimes be restored by a light exposure to nitric acid which passivates the surface, restoring the Cr-oxide layer. The carbon content is an important factor in corrosion preformance but so is the heat treatment. Under the wrong conditions and in different environments, all SSs can rust. One of the most common corrosion problems is sensitization which occurs in the heat affect zone (HAZ) around welds. If the C content is high enough and the heat is high enough, the Cr atoms in solid solution form Cr-carbides and are no longer available to form a protective Cr-oxide. The corrosion resistance can be restored by appropriate heat treatment.

- Q: I am reading the book The Cure For All Advanced Cancers by Hulda Regehr Clark.She writes for example: cancer can be caused by exposure to heavy metals, like nickel and chromium from stainless steel cookware. Stainless steel cookware releases chromium and nickel, two of the most carcinogenic metals.Are there any studies done measuring how much nickel and cadmium can be released from the regular use of stainless steel cookware?Is this a commonly accepted opinion that use of stainless steel cookware is dangerous?If not stainless steel, what kind of cookware to use? I heard that non-stick cookware also releases some harmful chemicals.

- Hi, I think that Stainless Steel is one of the safest ways to cook food. Glassware is also safe, but you must be careful not to drop the stuff, it can break and leave small pieces on the floor. Yes non-stick cookware can harm small fast breathing animals like birds in your house if the cookware overheats, but by keeping water or moisture in the bottom of the pan, and not using supper high heat, you can avoid overheating a non-stick surface. This also includes not scraping the surface with the utensils. Aluminum cookware, especially cast aluminum is considered by many as more than average toxic to many. Test for alltimers is that they contain aluminum in their bodies, and many owned aluminum cookware too. To kill cancer, look to Dr. Otto Warburg, who did win a Noble Prize for discovering how to kill the cancer cells.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- ...

- Q: How are steel coils used in the production of metal buildings?

- Steel coils are an essential component in the production of metal buildings as they are used to create the structural framework and outer cladding. These coils are unrolled and cut into sheets, which are then shaped and formed into various building components such as beams, columns, and panels. The strength and durability of steel make it an ideal material for constructing metal buildings, ensuring they are capable of withstanding harsh weather conditions and providing long-lasting structures.

- Q: What are the different types of steel grades used for coil production?

- There are various types of steel grades used for coil production, including carbon steel, stainless steel, and high-strength low-alloy (HSLA) steel. These grades are selected based on the specific requirements and application of the coils, such as strength, corrosion resistance, and formability.

- Q: Is there a chemical that can be applied (spraid, brushed, adhere) to a steel surface to decrease the heat conductive properties of the metal (so it doesn't heat up as quickly)?Thanks in advance!

- There is, but I don't know what it is made out of. It is probably some fireproof, foam material which acts like insulation. I doubt it is designed to resist abrasion however. Most things which adhere to metal surfaces are not flameproof, and those which do resist fire are not good insulators. For example, the ceramic coating of appliances like stoves and washing machines adhere very well and are fire resistant, but do not insulate. It was the failure of the steel insulation which caused the collapse of the world trade centers. The impact of the airplane tore away all the insulation on the supporting struts of the building and then the fire caused the steel to soften and break. Steel was once insulated by wrapping it in asbestos cloth and then applying plaster over this to form a shell. It did not actually adhere to the steel but it did insulate it, and was fireproof. However asbestos is a cancer hazard and a lot of old buildings are being stripped of their asbestos as a safety precaution. The asbestos can be replaced with fiberglass which is usually duct taped together.

Send your message to us

Currugated Color or Galvanized Steel Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords