Mullite Brick Corundum Brick Refractory Insulation for Heating Furnace in EAF

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corundum Brick Refractory Insulation Usage for Heating Furnace in EAF

Product Description for Corundum Brick

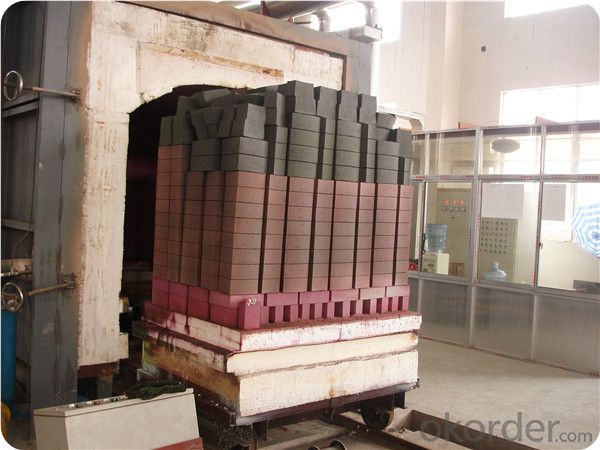

The products are produced by corundum and chromium oxide as main materials, formed from casting, being treated under high temperature.

Reheating furnace chrome corundum slideway brick. High-speed heat flow erosion and ball dynamic conditions of wearing and tearing, and the low-melting materials under high temperature erosion, infiltration of rotary kiln body, the demanding is rigour for the refractory materials. These materials have high temperature strength, wear resistance, corrosion resistance, long-life time and other excellent properties

Structure& Advantage for Corundum Brick

Characteristics of our corundum brick

1) After shaping and sintering, cutting and grinding processing are done, drilling is necessary according to brick drawings.

2) Little impurities of iron and alkali metal

3) High temperature resistance

4) uniform structure and high cold crushing strength

5) Good thermal shock resistance, stable volume, good insulation performance in high temperature

6) Low thermal conductivity

We Are Suppiler for

Below are some of our customers

Allied Mineral Products,inc

Refractories Incorporated

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

Raw Material for Corundum Brick

Image for Raw Material

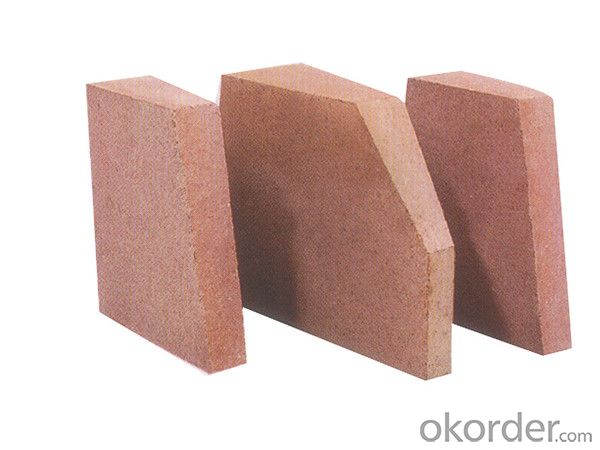

Major Images for Corundum Brick

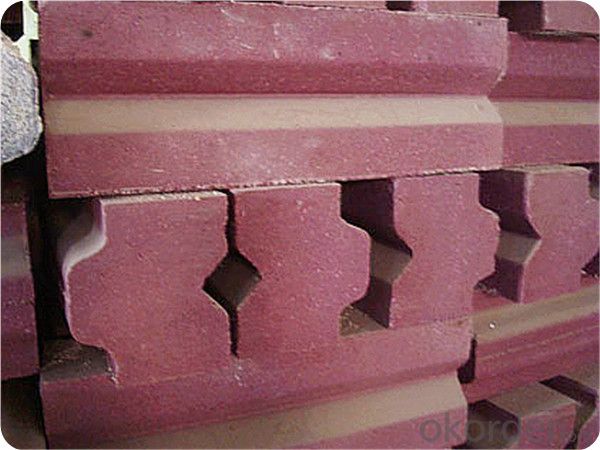

Corundum Bricks & Other Shape Bricks

Packaging & Delivery for Corundum Brick

1.The Corundum or Mullite Insulating Fire Brick will be packed as the standard of exporting or packed on wooden pallet with three layers water-proof shrink film and tightened with plastic/steel bandages,when in the transportation process,we should pay attention to moisture-proof and light handling.

2.The packing of Refractory Brick will accept customer's requirement if any.

3.Delivery within 7-15 working days after your payment.

4.Fast delievery accepted by customers.

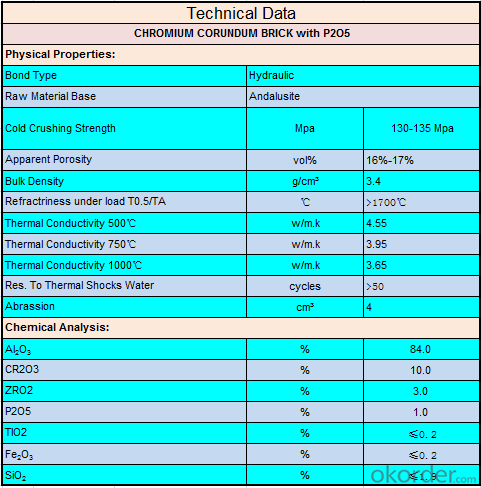

Specification

for Corundum Brick

Why Us

1. Strong professional:

We are state-owned company, ranking 267th/Fortune Global 500. We have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries.

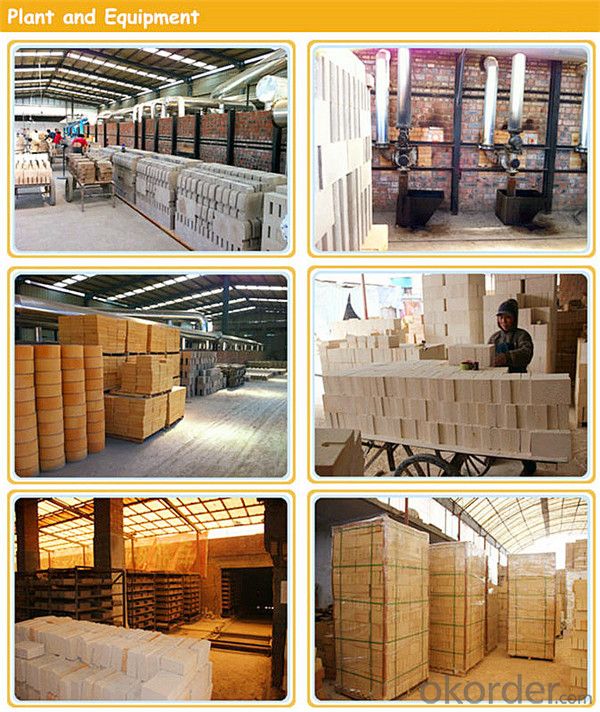

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory’ s production materials, process control, quality supervision and package delivery,and ensure the products are 100% qualified.

2. Annual supply:

Our company has passed ISO9001 quality management system certification and SGS certification. And the annual supply of shaped and unshaped refractory product is 28,800-35,000 tons..

3. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece,Spain, Congo, Angola, South Africa, and Maldives,Jordan and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Testing equipment;

Our company’s testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

FAQ for Corundum Bricks

3.Common question:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q: Aluminum content 38, silicon content 55 What refractory bricks?

- The mineral composition of the high alumina brick is determined by the bauxite used. The mineral composition of the clinker is usually mullite, corundum and glass. The theoretical composition of mullite is Al2O371.8%, SiO2 28.2%, and its melting decomposition temperature is 1840 DEG C. With acicular crystal, network cross structure, high temperature state showed better strength. Corundum in the form of alpha -Al2O3, melting point of 2050 degrees, hardness of Mohs 9, showing a granular and columnar crystal, has good chemical stability, acid, alkaline slag have a certain resistance. Based on the composition of mullite minerals, the phase composition of high alumina brick can be judged according to the content of Al2O3.

- Q: (refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- Is there a mark on the contract? Mark the items as required by the contract.

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q: What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- Corrosion resistance: mullite acid is not alkali resistant. Alpha alumina ceramic acid, alkali resistance - for floor tiles, alumina corrosion resistance is too high, unnecessary.Sintering temperature: the sintering temperature of mullite is low. So the cost is low because of this, so alumina ceramic is basically not used for floor tiles - unless it's too rich to burn.Heat shock resistance: the thermal shock resistance of mullite is higher than that of alumina.High temperature creep properties: the high temperature creep of mullite is higher than that of alumina, so mullite can bear higher weight at high temperature, and alumina is less.Resistance: alumina ceramic resistor is higher than mullite, so it is used as high-voltage insulators.

- Q: Mullite bricks in alumina alumina is what?

- Mullite (3Al2O3 - 2SiO2) high alumina refractory materials as the main crystal phase. The general alumina content in 65% ~ 75%. In addition to mineral composition of mullite, alumina containing low also contain a small amount of glass phase and cristobalite; alumina containing high also contain a small amount of corundum. Highrefractoriness, up to over 1790 DEG C 1600. Load softening start temperature to 1700 DEG C. Compressive strength at room temperature is 70 ~ 260MPa.. The thermal shock resistance of sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or alum clay as binder, forming and sintering made of fused mullite bricks with high alumina and bauxite, refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite than sintered mullite, thermal resistance Shock resistance than sintered products. The uniformity of content in alumina mainly depends on their high temperature properties and mullite phase and glass distribution. Mainly used in blast furnace, furnace top and bottom furnace, glass furnace regenerator, sintering kiln, petroleum cracking system dead lining.

- Q: Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- In the presence of excess EDTA in the acidic medium, the aluminum is complexed with EDTA, and the remaining EDTA is complexed with lead salt, and then the EDTA complexed with aluminum is replaced by sodium fluoride, and the lead salt is substituted...

- Q: The introduction of mullite brick

- High alumina refractory with crystalline mullite (3Al2O3, 2SiO2) as the main crystal phase.

- Q: The difference between the high aluminum corundum brick and corundum mullite brick

- Wall tiles and floor tiles are collectively referred to as ceramic tile flooring

- Q: What are the varieties of polycrystalline mullite?

- PNF-100 seriesThe PNF-100 series are made of polycrystalline mullite fiber cotton felt to cut, compress, and wrap into blocks without any adhesive.Characteristic: thermal shock resistancelow thermal conductivityLight weightSound absorption propertyLow thermal storage

- Q: Refractory bricks (mullite bricks) can be used on the walls of buildings?

- In many architectural design, high-rise fire rating is placed in the important position of the topic, especially when the floor height is more than 20 layers, we have more stringent requirements for the choice of fire resistant materials. The building wall, kitchen flue, boiler flue, flammable zone must use a firewall barrier, in many refractory refractory brick is the product of choice for fire resistance of refractory brick masonry is more stable.

Send your message to us

Mullite Brick Corundum Brick Refractory Insulation for Heating Furnace in EAF

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords