Corundum Mullite Insulating Brick for Ceramics Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mullite Insulating Brick,Mullite Corundum Brick for Ceramics Furnace Lining

Corundum bricks is widely used in oil gas gasifier, ethylene-generated furnace, and ammonia decomposing furnace in petrochemical industry, carbon black reactor in chemical industry, and high temperature kilns in refractories and ceramics industry.

Corundum bricks has gained the Third Prize of Science & Technology Progress from Sinopec and the former Ministry of Metallurgy Industry.

The brick has been used in the thermal equipment of domestric made or imported. It has been exported and used in German Texaco gasifier with good performance.

Product Applications:

Corundum Mullite Brick are ideal for use in the below applications

Corundum mullite brick is mainly used as superstructure, feeder channel and cover plate in glass furnace. It can also be used as lining of high-temperature kiln and mesothermal carbon black reactor, the shed bar of kiln car, pusher plate of electronic magnetic material industry, etc.

Product Advantages:

CNBM has success in its Corundum Mullite Brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

1.High refractoriness under load

2.Excellent corrosion resistance to both acid and alkali

3.Good thermal shock stability

4.High density

5.Neutral material

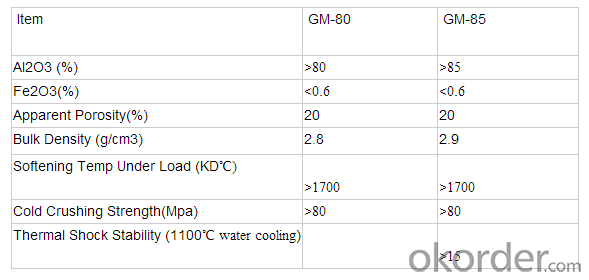

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

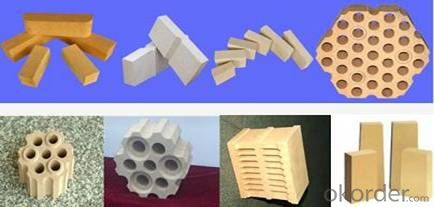

Product Picture

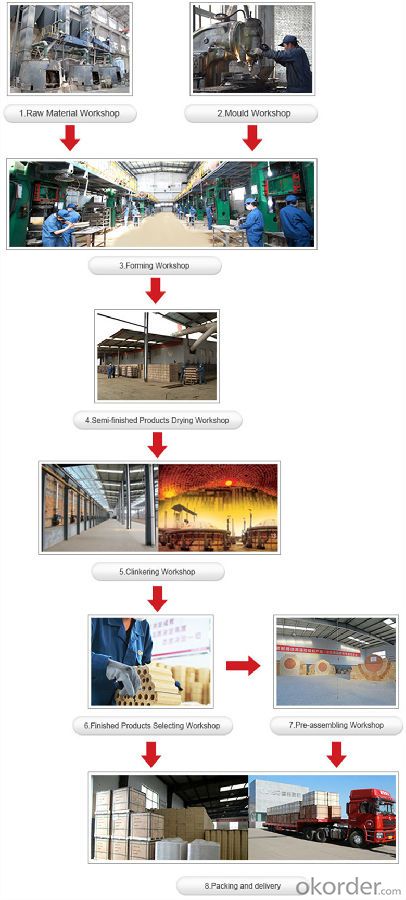

Produce Processing

- Q: Application of electric high temperature regulating valve?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, there are refractories for special occasions.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q: What material is used in an iron smelting furnace?

- In fact, refractory refractory ah is special ceramic frequently used AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: How to improve the induction furnace campaign, from the promotion of refractory life start

- According to the workpiece, choose the appropriate hardware castable, corundum brick or refractory bricks, etc.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- High alumina brick is a kind of refractory material in refractory brick products. It is made of refractory clay or other refractory material. It belongs to the product of Si Al System

- Q: Is liquid phosphoric acid two aluminum hydrogen flammable?

- Two aluminum liquid hydrogen phosphate using spray paint, cement, refractory castable and binder for foundry industry, mainly used in refractory industry corundum, chromium corundum nozzle coal water slurry gasifier with chromium aluminum zirconium corundum brick production.

- Q: What are the refractory materials?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 93% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, low thermal shock resistance. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q: What kind of rock is corundum produced?

- Aluminum oxide (Al2O3) mineral. Due to Mohs hardness of up to 9, mainly used as high-grade abrasives. The crystal belongs to the three party system, a dolioform six square column, some are needle or plate. Aggregates are massive or columnar. Usually white, gray, yellow and other colors. If a small amount of Cr3+ is red, a ruby is called;

- Q: What can zirconium sponge do for those industries?

- Uses: aerospace, military, nuclear reactions, atomic energy, and metal superhard materials, the manufacture of bulletproof alloy steel, can also be used in the reactor uranium fuel coating alloy; zirconium at high temperatures easy to launch electronicProduct characteristics: zirconium metal has very strong corrosion resistance, ultra high hardness and strength

Send your message to us

Corundum Mullite Insulating Brick for Ceramics Furnace Lining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords