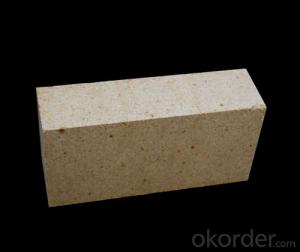

Mullite Brick - MS60

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Ton m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Mullite Brick-MS60 Our mullite brick is a kind of high alumina refractory brick which takes the mullite (3Al2O3 · 2SiO2) as the basic crystalline phase. Alumina content is generally from 65% to 75%. Featuring high compressive strength, good thermal stability and strong impact resistance. It can be made into any specification defined by users to fit for different demands. It also has the capacity of maintaining excellent mechanical behavior under high temperature, Mullite Brick-MS60 Physical Properties: Refractoriness ℃ 1790 Permanent Linear Change(1500℃×3h)% % ±0.1 Apparent Porosity, % % ≤20 Cold Crushing Strength Mpa 50 Refractoriness Under Load (T0.6) ℃ ≥1600 Density g/cm3 ≥2.45 Chemical Analysis: Al2O3 % ≤60 Fe2O3 % ≤1.2 Note: Features of Mullite Brick-MS60 High refractoriness Excellent thermal shock resistance Excellent mechanical strength Applications of Mullite Brick-MS60 Our Mullite Bricks are commonly used in glass furnace, heating furnace, chemical kiln and metallurgic furnace. CNBM has success in its refractory bricks due to their cost-effectiveness and excellent insulating properties. CNBM also has experience in refractory brick application and would like to assist you in product selection, system design, and installation techniques. We are looking forward for your inquiry.

Technical Data are typical average results from test pieces. The technical data is offered solely for your consideration. And CNBM reserve the right to modify the technical data without any prior notice. Users of CNBM products should make their own tests to determine the suitability of each product for their particular purposes.

- Q: (refractory castable, silicon carbide brick, mullite bricks etc.) do testing should be commissioned by the project? What are the specific qualification standards? Thank you

- Compressive strength, volume density, flexural strength, thermal shock resistance, high temperature load, creep temperature, refractoriness, etc.. There should be GB

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity.

- Q: What is the difference between mullite ceramics and alumina ceramics? Can you tell me something to do with floor tiles?

- Mullite is formed by the reaction of alumina with silica. The main difference between him and alumina is that:Hardness: alumina is harder than mullite, but two are tough enough, and are not easy to break.Corrosion resistance: mullite acid is not alkali resistant. Alpha alumina ceramic acid, alkali resistance - for floor tiles, alumina corrosion resistance is too high, unnecessary.

- Q: What is the price of refractory bricks?

- The refractory insulating brick generally refers to light brick, normal furnace lining are using this brick kiln will not increase the weight, and good heat insulation effect and ordinary insulating brick production are made of clay, high alumina high strength low iron bead brick, mullite, high aluminum light insulating firebrick, diatomite insulating refractory brick, the use of light heat insulation brick can increase the use of space, and good insulation effect

- Q: Mullite bricks in alumina alumina is what?

- Mullite (3Al2O3 - 2SiO2) high alumina refractory materials as the main crystal phase. The general alumina content in 65% ~ 75%. In addition to mineral composition of mullite, alumina containing low also contain a small amount of glass phase and cristobalite; alumina containing high also contain a small amount of corundum. Highrefractoriness, up to over 1790 DEG C 1600. Load softening start temperature to 1700 DEG C. Compressive strength at room temperature is 70 ~ 260MPa.. The thermal shock resistance of sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or alum clay as binder, forming and sintering made of fused mullite bricks with high alumina and bauxite, refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite than sintered mullite, thermal resistance Shock resistance than sintered products. The uniformity of content in alumina mainly depends on their high temperature properties and mullite phase and glass distribution. Mainly used in blast furnace, furnace top and bottom furnace, glass furnace regenerator, sintering kiln, petroleum cracking system dead lining.

- Q: Jm26 mullite aluminum content in the number, ask God to answer. 23 more. How is this identified with the naked eye?

- In the presence of excess EDTA in the acidic medium, the aluminum is complexed with EDTA, and the remaining EDTA is complexed with lead salt, and then the EDTA complexed with aluminum is replaced by sodium fluoride, and the lead salt is substituted...

- Q: The introduction of mullite brick

- High alumina refractory with crystalline mullite (3Al2O3, 2SiO2) as the main crystal phase.

- Q: Mullite brick

- High refractoriness, up to 1790 degrees celsius. The softening start temperature is 1600~1700 degrees. The compressive strength at normal temperature is 70 ~ 260MPa. Good thermal shock resistance. The sintered mullite and fused mullite brick two. Sintered mullite brick with high bauxite clinker as the main raw material, adding a small amount of clay or raw bauxite as binder, after molding, sintering and made. Fused mullite brick with high bauxite, alumina and refractory clay as raw material, adding charcoal or coke fines as a reducing agent, formed by reduction of electric melting method to manufacture. The crystallization of fused mullite is larger than that of sintered mullite, and the thermal shock resistance is better than that of sintered products. Their high temperature performance mainly depends on the content of alumina and the uniformity of the phase distribution of mullite and glass. [1]

- Q: What are the varieties of polycrystalline mullite?

- Performance comparisonWe used chemical method to produce a microcrystalline structure, excellent thermal stability, temperature exceeds the 300~400. C.The small fiber diameter uniform, slag ball trace, bulk density for 1/2~1/3 products.The large amount of fiber products, high porosity, low coefficient of heat conductivity.It has large surface area, is the ideal material for high temperature catalytic carrier.

- Q: Refractory bricks (mullite bricks) can be used on the walls of buildings?

- Mullite refractory bricks can be used in construction, but their price is too high. We choose high alumina brick to meet the demand.

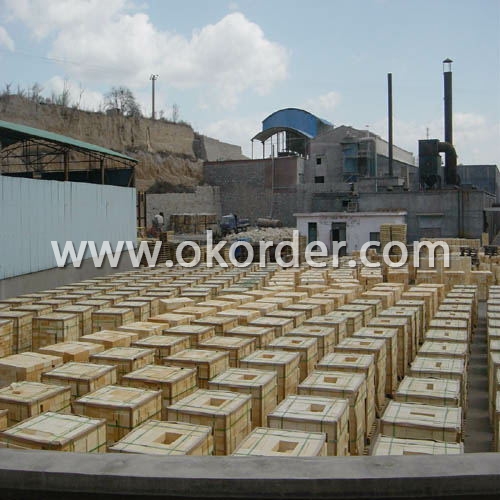

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 2007 |

| Annual Output Value | Above US$ 60 Million |

| Main Markets | Mid East; Eastern Europe; North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 31% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 36,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Mullite Brick - MS60

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5 Ton m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords