Corundum Mullite Insulating Brick for Ceramics Furnace Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details for Mullite Insulating Brick,Mullite corundum Brick for Ceramics Furnace Lining

| Place of Origin: | China (Mainland) | Brand Name: | Type: | Mullite Brick | |

| Porosity: | Solid | Size: | According to the customer's requirements, According to the customer's requirement | Color: | White |

| Function: | Firebricks | Feature: | Thin Bricks | Technique: | Sintered |

| Bulk density(%): | 1.0-1.3kg/m³ | Mix woriking temperature(℃): | 1550℃-1650℃ | Linear change rate(%): | 1520-1630℃x4h±0.5 |

| Export Markets: | Global | HS Code: | 6902900000 | Refractoriness under load ℃: | 1520℃-1630℃ |

| Application: | High temperature Furnace lining | Cold crushing strength(Mpa): | 4.2-8Mpa | The normal temperature(℃): | 1520-1630℃ |

Packaging & Delivery

| Packaging Details: | Be packed in fumigated wooden pallets |

| Delivery Detail: | With in 20 days after the advanced payment |

Specifications

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. High insulation

Characteristics

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. Low heat capacity

4. Low content of impurities

5. High insulation

6. Excellent thermal shock resistance

7. Low density

Physical and chemical index

| Performance and application | Light Weight Mullite Brick | |||

| Al2O3 % | ≥58 | ≥72 | ≥78 | |

| Bulk density g/cm3 | ≥1.0 | ≥1.2 | ≥1.3 | |

| Cold Crushing Strength Mpa | 4.2 | 6 | 8 | |

| Refractoriness under load °C | ≥1520 | ≥1580 | ≥1630 | |

| Liner Change on Reheating% | ±0.5(1520°C*4h) | ±0.5(1550°C*4h) | ±0.5(1600°C*4h) | |

| Thermal shock stability (water-cooling) frequency 1100 °C | ≥20 | ≥20 | ||

| W/m.K≤ | 0.381 | 0.398 | 0.426 | |

| Max application temperature°C | 1550 | 1600 | 1650 | |

Buyer Notes

Maybe our price is not the lowest, but our quality is the most trusted.Our marketing team is very professional and responsible.We have been considering the product quality and company reputation as important as our lives and this is why more than half of our products are exported to foreign countries.Welcome to inspect our factory and welcome to come to test the quality of bricks before delivery.

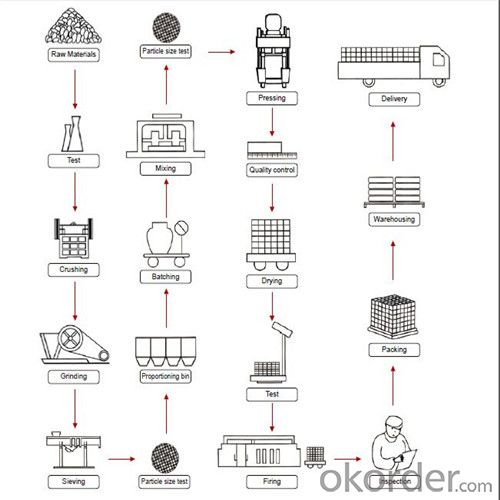

General Purchase Process

Inquiry

Quote

Signe a purchase contract

Pay advance payment

Production and delivery (before delivery, welcome to our factory to inspect)

Pay the balance

Delivery

After-sales service

Brand Advantage

Location:Located in the hometown of refractory, Zibo, Shandong Province

Raw materials:The location of our factory is rich in excellent raw materials needed by refractory.

Focus:Only focus on the production of silicon and aluminum refractory products

Professional:Own a professional technical team engaging in the refractory for more than 20 years

Life:High-qualified raw materials and strict production process extend the useful life of the product.

Quality:The quality of products is well-known as high quality and stability.

Services:A professional and experienced marketing team

Credibility:Ensure orders be completed on time and in quality to gain time and interests for our customers

Service Advantage

Professional:Familiar with international trade process and international customs and practices

Friendly:Friendly, warm, kind and hospitable

Quickly:Always response and deliver goods with the fastest speed

Strict:Using strict work attitude to avoid errors

Logistics control

Deliver goods with the fastest speed

Our goal is to prepare, be quick, and provide courteous services.

Strict testing processes to ensure the 100% of pass, 100% of customer satisfaction.

Perfect package to ensure no damage in the course of delivery

Five Guarantees

Guarantee direct sales

Guarantee the safety of funds

Guarantee delivery on time

Guarantee the quality

Guarantee services

One-stop service

Dealing a full range of products, we provide customers with the one-stop service of purchasing refractory materials.For some refractory products that our company does not produce, we can help purchase and deliver if the customer needs.We will make every effort to provide maximum convenience and high-speed to customers, and do our best to answer all of our customers' problems and meet all their needs.

Welcome to inspect and look around our factory.Hope to seek cooperation and development with you.

Warmly welcome friends and customers all over the world to pay a visit to factory!Hopefully both of us can establish a long-term cooperation!

FAQ

3.Common question:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories,at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time,seeing is believing.

Q3:What is the whole process of doing business with us?

A:1.First,please provide details of the products you need we quote for you.

2.If price is acceptable,we provide Proforma Invoice.If need the sample to do a test,we will send a sample to PI to you for doing the payment.

3.If client approve sample and require for sample production for order,we will provide Proforma Invoice for client.and we will arrange to produce at once when we get 30% deposit.

4.We will send photos of all goods,packing,details after goods are finished.After be confirmed by clients,Pls transfer the balance 7.% for the order.We will arrange shipment and send all orginal docs to you.

Q4: What advantages we have?

A: 1.Rich experience:We have more than 10 years experience in this industry.That means,we can preview the problems for the orders and products. Therefore,it will make sure to reduce the risk of bad situation to happen.

2.Best technique:We have a strong technique team so that can explain the usage process and settle technique problem for production.If you need,we can visit your company to offer the technique support for your produce line.

3.Offer all line service:For the new manufacture,we can offer professional guidance and offer complete set material to you for your products which you need to make.

4.Point to point service:There is one sale who will serve you from inquiry to products shipped out.During the process,you just need to discuss with her for all problems and the way saves much time.

5.Free design:for the mold,If you are not ready for the designs,the professional designers will be able to help you with it freely, you just offer size is ok.

6.Strict QC:For each order,strict inspection will be carried out by the QC department before shipping. The bad quality will be avoid within door.

7.Shipping:We have shipping department and forwarder,so we can promise faster delivery and make the goods well protected.

Thanks for your coming in,if there is any question,I will be glad to help you.

Welcome to enquire!

We will offer you the best price with high quality!

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- AZS33 is the casting of AZS series of the largest, most widely used in tea, to prevent the pollution of liquid glass is excellent. Widely used in the glass furnace pool wall, pool bottom, the upper structure and feeding routes and other parts.

- Q: How much is a refractory brick?

- This question is too general, refractory bricks according to the use of the environment and industry, there are a variety of materials, a variety of specifications, prices vary greatly.

- Q: What are the advantages of refractories?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: What refractory materials are used in industrial furnaces?

- The working conditions of industrial furnaces should first be investigated thoroughly, and the primary and non essential factors affecting the construction of furnace materials shall be analyzed. Focus on thinking, the temperature change condition, temperature bump slag properties, furnace atmosphere, heat insulation, impact wear and other special requirements, to ensure the quality of the life and product.

- Q: What refractory materials are adopted in each part of the blast furnace?

- The furnace throat is a part of the direct impact and friction when the burden drops, and the high density and high alumina brick is usually adopted. The upper and middle shaft temperature is only 400~800 degrees, the parts with high alumina brick and sillimanite brick.

- Q: High temperature refractory material?

- Many kinds of refractory materials, usually by refractoriness level is divided into ordinary refractory materials (1580 to 1770 DEG C), advanced refractories (1770 to 2000 DEG C) and special refractories (more than 2000 DEG C); according to the chemical characteristics into acid refractory material, refractory materials and basic refractory materials. In addition, the refractory material used for special occasions.

- Q: What are the main constituents of refractory bricks?

- Brick, refractory brick is containing more than SiO293%, is the main varieties of acid resistant brick. It is mainly used for coke oven building, also used in furnaces all kinds of glass, ceramic and carbon calciner, refractory brick arches and other load-bearing parts, is also used in high temperature bearing part of hot blast stove, but should not be used in thermal equipment below 600 DEG C and the temperature fluctuation in the.

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: What is the difference between T3 refractory bricks and high alumina refractory bricks?

- High aluminum refractory brick brick is all in one type of material classification, the material is AL2O3 high bauxite content above 55%, refractory brick by material into clay bricks, high aluminum brick brick brick corundum brick

- Q: What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- The expansion curves of fused cast AZS brick at 1000 DEG C near a crystal anomaly, its internal changes of ZrO2 crystal are reversible, with large volume change, therefore, products containing ZrO2, should not be used in the temperature of 1000 DEG C, often have sharp fluctuations in the position. When baking the kiln, the temperature can not be too large at 900~1150 degrees centigrade. Generally, the temperature can not exceed 15 degrees /h, and the temperature should be raised steadily. Some parts to prevent the cold, with other brick protection, to prevent explosion.

Send your message to us

Corundum Mullite Insulating Brick for Ceramics Furnace Lining

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords