Corundum-Mullite Brick with High Refractoriness for Metallurgic Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Mullite Brick

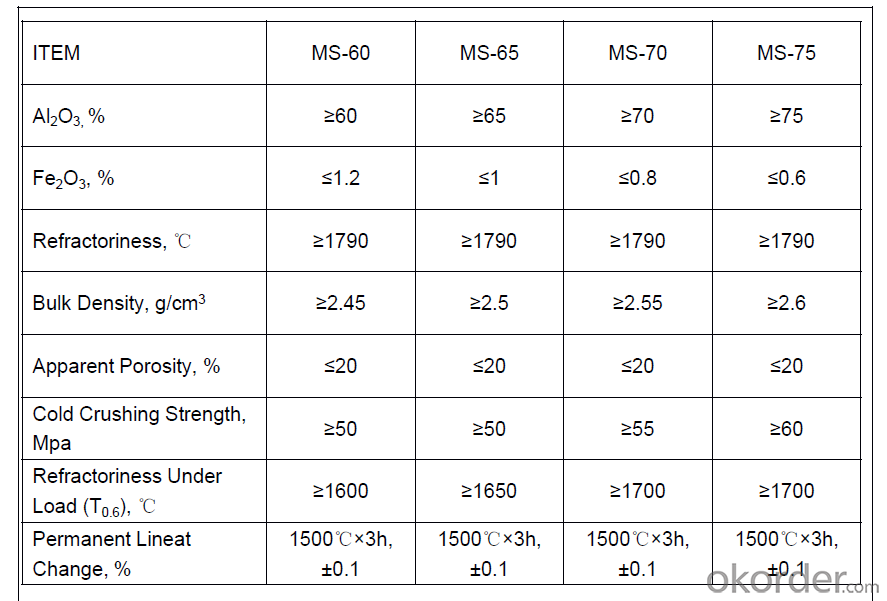

CMAX mullite brick is a kind of high alumina refractory brick which takes the mullite (3Al2O3 ? 2SiO2) as the basic crystalline phase. Alumina content is generally between 65% to 75%

Feature of Mullite Brick

High refractoriness

High compressive strength

Application of Mullite Brick

Glass furnace

Heating furnace

Chemical kiln

Metallurgic furnace

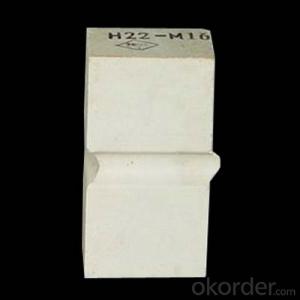

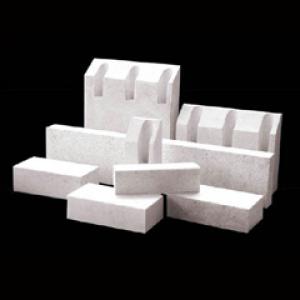

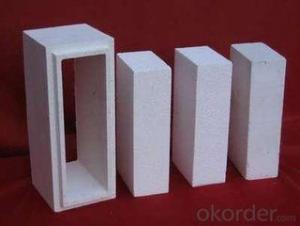

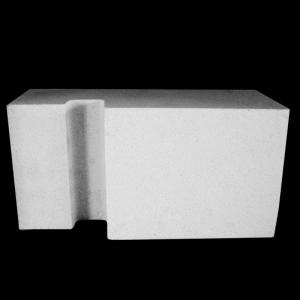

Images of Mullite Brick

Technical Data of Mullite Brick

Company Introduction

Who CNBM is

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

What CNBM Can Do

We can supply ALL KINDS OF REFRACTORIES BRICK/CASTABLE and CERAMIC FIBER PRODUCTS in high quality and competitive price.

What Certification CNBM Have

FAQ

If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

How do you control the products quality?

With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervisor.

I’m not satisfied with the refractory materials I used before, can you propose more suitable pro

Yes. Please give us the problems you faced, your requirements and the technical data of the products you used before. That we will give you our suggestion and propose the solution based on your special requirements.

What’s the lead time for my order?

It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Can you offer Door-to-Door delivery?

Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

What is the minimum quantity?

There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: Mullite bricks in alumina alumina is what?

- With mullite as main crystalline phase of high alumina refractory products. Mullite bricks containing Al2O3 64%~75%, refractoriness >1790? C, normal temperature compressive strength 70~260MPa, softening the starting point for 1600~1700 degrees. The manufacturing method for casting and sintering process.

- Q: What are the properties of corundum mullite?

- Lightweight materials have uniform internal structure, high compressive strength, corrosion resistance, heat shock resistance, oxidation resistance, high temperature and low thermal conductivity. Dongshin refractories manufacturers manufacturers supply, price is appropriate

- Q: Corrosion mechanism of iron on refractory materials

- But you can do refractory additives. Iron oxide paints are widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color. For example: 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more

- Q: 2000 degree of high temperature materials, which belong to high temperature insulation materials?

- What can withstand 2000 degree high temperature materials on the market? What are the materials belong to high temperature materials? High temperature insulation material the most common are the following: calcium silicate shell, aluminum silicate cotton felt, glass surface, diatomite, vermiculite, foamed cement etc.. Among them, the first three are the most common, especially the aluminum silicate cotton felt, which can withstand 650 degrees of high temperature.

- Q: What material is heat insulated and not afraid of fire?

- According to the different raw materials are divided into rock wool and slag cotton. In 1840, the United Kingdom to achieve the melting of slag after the formation of fibers, produced slag cotton, used for building insulation, so far more than 160 years of history. Features are: thermal insulation performance, also has the fire characteristics, good sound absorption and vibration damping effect, but different materials of mineral wool class containing asphalt, glue or other organic material, easy to produce harmful substances and environmental pollution, low intensity, as the maintenance of the structure of the thermal insulation layer is easy to collapse, the production process is more complicated has been replaced by other materials.

- Q: What are the high temperature insulation materials?

- Followed by a variety of lightweight bricks, alumina hollow ball, lightweight brick is relatively high temperature, about 1600 degrees. The others are low.Then there's the heavy brick. Heavy alumina brick, corundum mullite, can withstand 1750 degrees -1800 degrees. Mullite, cordierite lower lows.

- Q: What kind of refractory material is used in the hearth of reverberatory furnace?

- The use of temperature ceramic fiber long 950-1260 in general, there are many domestic manufacturers do not understand the deceive customers, often in accordance with the classification of temperature to the material sold to customers, such as zirconium ceramic fiber belongs to the 1400 type, but the long-term use temperature of 1260 degrees or less, impossible to maintain 1400 degrees to 1260 degrees, so the equipment in order to use ceramic fiber, high grade can only be used on polycrystalline fiber

- Q: What material is good for refractory bricks?

- The mineral composition of high alumina refractory brick and high alumina refractory brick is corundum, mullite and glass phase. The raw materials are high alumina and sillimanite natural ore. They are also made of fused alumina, sintered alumina, synthetic mullite and calcined alumina in different proportions with clay. It is produced by sintering process. But the products are casting brick, brick, brick fused grain and unshaped refractory brick. High alumina refractory brick is widely used in iron and steel industry, non-ferrous metal industry and other industries.

Send your message to us

Corundum-Mullite Brick with High Refractoriness for Metallurgic Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords