Corrugated Sheets /Steel Manufacturer/ /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

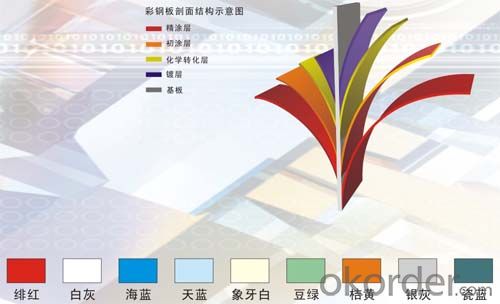

1.Corrugated Sheets Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications Corrugated Sheets :

* Used as roof panel, wall panel in steel structure in warehouse, factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction, animal husbandry, fishery and commerce, etc,

3.Corrugated Sheets information:

Product | Coated Surface Treatment Mental steel |

Base Material | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

Color | All RAL Color,or be customized |

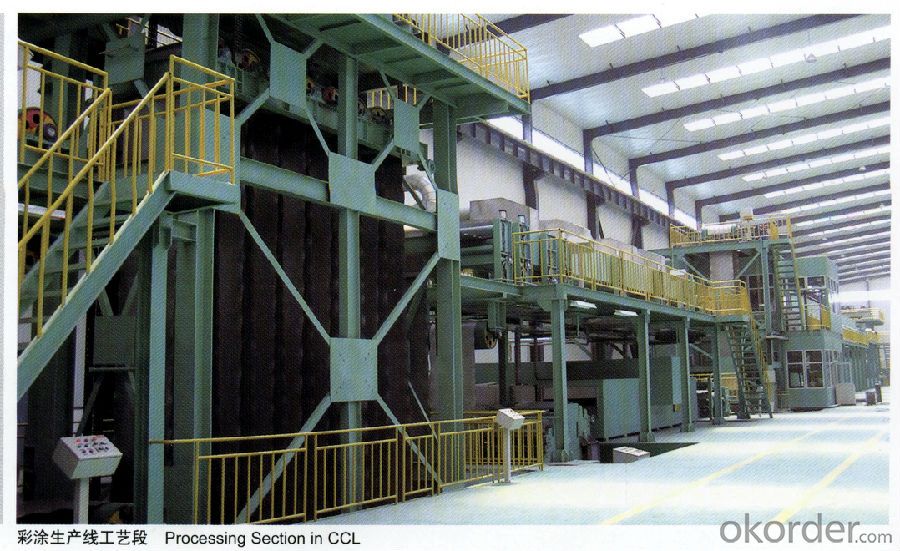

Equipment | Double coating double baking; three coating three painting |

Production Capacity | 500,000 Tons per Year |

Size | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

Zinc Coating | 30g/m2-150g/m2 |

Thickness | Top Side: 10-25 microns; Back Side: 4-8 microns |

Coil Weight | Normally 5 Tons per Coil, aslo as required by customer |

Coil ID | 508mm/610mm |

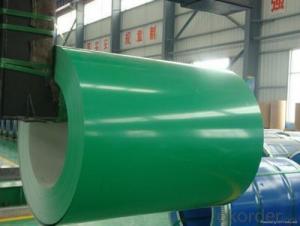

4.Corrugated Sheets image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Ok, lately I've been taking to making things out of stainless steel chain mallie rings. The problem is that when i make a bracelet or something, the area around the fastener always looks pretty bad. I'm thinking to have a friend who also does chain mallie finish the weave all the way around. This would make it look good but make it impossible to remove.Are there any long term problems with stainless steel on skin? I know some metals will change the color of the skin or make the skin absorb some of the metal. Is this something to worry about with stainless steel?

- Stainless steel contains both nickel and chromium. These two alloys are responsible for most of contact dermatitis in people. Some of my co-workers making steel had such bad reactions to chromium that they had to quit their jobs. Their skin was always inflamed. People don't react to finished stainless steel the same way because the alloys are bonded tightly in the heat treating process. But if you are grinding it and getting the dust on your skin, you could get a contact dermatitis if you are sensitive. I don't think it would absorb into your blood stream or do any long term damage to your skin. If you do get a reaction, you would have to cease your exposure or in a worse case scenario risk getting a body wide reaction like my coworkers. I would not worry about any exposure making rings out of stainless steel. After all, stainless steel is used in sugical implants and most people are fine.

- Q: So, I'm looking into steel toe paddock boots. I'll be using them around horses, horses that I don't know and that are rescue horses. I'm currently looking at Equitector the Moorland paddock boots. They're $200, and I think I have to order them online. I like boots that are this style (the Moorland style)... Is there any other brand of boots that has steel toe paddock boots, that are cheaper or that I can buy in stores?

- I personally know a trainer who is friends with a cowboy who got his toes amputated by a horse stepping on his steel toed boot. I personally prefer a broken toe or a bruised toe. I wouldn't recommend them. If you get your toe stomped and you happen to be standing on pavement or other hardpacked surface...you're going to regret you ever bought them. there's a reason why not a lot of horse people wear them. As for price....$200 is an average price for good boots of any kind. My first western leather boots were Tony Llamas and they were $200. I bought them YEARS ago and they're still just great.

- Q: What is the difference between steel coils and steel sheets?

- Steel coils and steel sheets differ primarily in their form and dimensions. Steel coils are long, continuous rolls of steel that have been wound up after being processed. They are typically produced in large quantities and are used in various industries, such as automotive and construction. Steel sheets, on the other hand, are flat pieces of steel that have been cut from coils or directly produced in a flat form. They come in different sizes and thicknesses, making them more suitable for specific applications such as roofing, cladding, or fabrication. In summary, while steel coils are the raw material for steel sheets, the main distinction is that coils are long rolls, while sheets are flat pieces of steel.

- Q: What are the different methods of testing the mechanical properties of steel coils?

- There are several methods for testing the mechanical properties of steel coils. Some commonly used methods include tensile testing, hardness testing, impact testing, and bend testing. Tensile testing measures the strength and ductility of the steel by applying a tensile force until it breaks. Hardness testing determines the resistance of the steel to indentation or scratching. Impact testing measures the ability of the steel to withstand sudden forces or shocks. Bend testing evaluates the flexibility and resistance to cracking of the steel by bending it to a specific angle. These methods help assess the quality and performance of steel coils in various applications.

- Q: How are steel coils coated for corrosion resistance?

- Steel coils are typically coated for corrosion resistance using various methods such as hot-dip galvanizing, electroplating, or applying a protective layer of paint or powder coating.

- Q: What is the difference between a steel strip and a coil? The steel strip is flat steel, and the steel coil is made of steel. Is that correct?

- A steel strip is a steel strip of relative range, and can be called a steel strip when the width is less than 1000.

- Q: I work at a tool store. I told my boss last week we needed more pruning shears so he did get more of all kinds. Thing is out of all of the shears he brought Two of different kinds say they are made out of Japanese steel. I have never heard of Japanese steel so now i ask you (the public) whats the difference between it and steel from the US or any other country? Those shears are worth more then the ones he gets from Mexico and China and even more than Black and Decker, Fiskars, etc but not more then Corona brand ones.

- I doubt japanese steel has any special quality in its own, but they might just be higher quality shears. For example, Chinese qualities are good depending on what they are, but are usually not professional made with the greatest equipment. Same for Mexico. The company that makes them might just put more effort into making sturdier and sharper shears and thus make them more expensive, but Corona might make them a bit better so they are priced less than Corona's.

- Q: What are the dimensions of steel coils used in the metal container industry?

- The dimensions of steel coils used in the metal container industry can vary depending on the specific requirements of the industry and the type of container being produced. However, typical dimensions for steel coils used in this industry range from 0.3mm to 3mm in thickness and 600mm to 2000mm in width. The coils are typically wound in a continuous spiral shape, with diameters ranging from 600mm to 1500mm. These dimensions allow for efficient production and handling of the steel coils during the manufacturing process of metal containers.

- Q: I have a knife with 154cm steel on it and I always here that you should put oil on it to keep it from rusting but I am just wondering what kind of oil? And how do I apply it and do I just leave it on there?

- It's stainless steel so it doesn't really need to be oiled. Anything will do for oil if you want to wipe it down. Just put a little on a paper towel and give it a once-over.

- Q: What are the common welding defects in steel coils?

- During the welding process, various defects can occur in steel coils. These defects encompass: 1. Porosity: Gas entrapment during welding results in small holes or voids in the weld metal. This defect weakens the weld and increases its vulnerability to corrosion. 2. Insufficient fusion or incomplete penetration: Inadequate fusion between the base metal and weld metal or incomplete penetration of the joint leads to this defect. A weak or brittle weld is the consequence. 3. Cracks: Cracks can manifest in the weld metal or the heat-affected zone (HAZ) of the base metal. They are caused by factors like high stress levels, improper cooling, or insufficient preheating. Cracks significantly reduce the weld's strength and integrity. 4. Undercutting: Excessive melting of the base metal at the weld's toe creates a groove or depression known as undercutting. This defect weakens the weld and concentrates stress, potentially leading to failure. 5. Excessive spatter: The welding arc expels small droplets of molten metal, which can land on the steel coil's surface. Too much spatter results in a rough or uneven surface finish and necessitates additional cleaning or grinding. To minimize these welding defects in steel coils, it is vital to ensure proper weld preparation, including thorough cleaning to remove any contaminants from the steel's surface. Moreover, utilizing the correct welding parameters, such as appropriate heat input and travel speed, helps minimize defects. Regular inspection and quality control measures also aid in detecting and addressing defects before they escalate into more serious issues.

Send your message to us

Corrugated Sheets /Steel Manufacturer/ /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords