Coated Surface Treatment Mental steel /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Coated Surface Treatment Mental steel Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of Coated Surface Treatment Mental steel

.Used as roof panel, wall panel in steel structure in warehouse, factories exhibition hall container houses, cold storage

.It is also mainly used in light industry, automobile, construction, animal husbandry, fishery and commerce, etc,

3.Product Introduction information:

| Product | Coated Surface Treatment Mental steel |

| Base Material | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| Color | All RAL Color,or be customized |

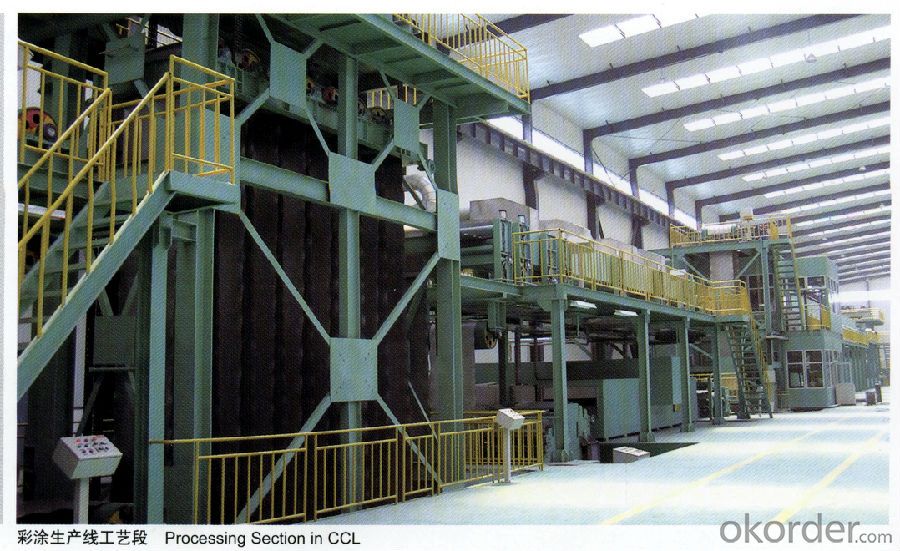

| Equipment | Double coating double baking; three coating three painting |

| Production Capacity | 500,000 Tons per Year |

| Size | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| Zinc Coating | 30g/m2-150g/m2 |

| Thickness | Top Side: 10-25 microns; Back Side: 4-8 microns |

| Coil Weight | Normally 5 Tons per Coil, aslo as required by customer |

| Coil ID | 508mm/610mm |

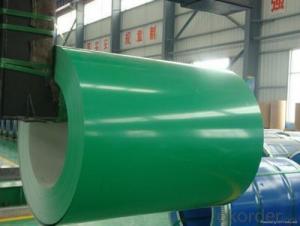

4.Color Coated Galvalume Steel Coil image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the weight of a standard steel coil?

- The weight of a standard steel coil can vary depending on its size and thickness. However, a typical range for a standard steel coil is between 5,000 to 10,000 pounds (2,268 to 4,536 kilograms).

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- From what I understand m390 is a new steel (at least for benchmade) so there doesn't seem to be a consensus on how it performs. Looking at the table, it should be very corrosion resistant. I'd guess it could be classified as a stainless steel. Sorry I don't have more info for you. EDIT: here's a link from the steel manufacturer. I hope this info helps.

- Q: How are steel coils used in the production of industrial equipment?

- The utilization of steel coils is essential in the manufacturing of industrial equipment. These coils, which are large sheets of steel that are flat and rolled, serve as vital raw materials for various manufacturing processes. To begin with, steel coils are employed for the purpose of fabrication. They are cut, shaped, and welded together to form the structural framework of industrial equipment. This encompasses machinery, heavy-duty vehicles, storage tanks, and other components utilized in industries. The coils provide the necessary strength and durability to withstand the demanding conditions faced by industrial equipment. Furthermore, steel coils are frequently molded into specific shapes to produce various parts and components used in industrial machinery. These parts may include gears, shafts, bearings, brackets, and many others. The malleability of steel allows for easy manipulation and fabrication into different sizes and shapes, making it an ideal material for such applications. Moreover, steel coils are also utilized in the construction of industrial equipment, particularly in the production of boilers, heat exchangers, and pressure vessels. These coils are typically fashioned into tubes or pipes, which are then welded or brazed together to create the necessary structure for such equipment. The high strength and heat resistance properties of steel make it the preferred material for these applications, ensuring the safe and efficient operation of industrial processes. In conclusion, steel coils play a pivotal role in the manufacturing of industrial equipment. They serve as raw materials for fabrication, are transformed into parts and components, and are used in the construction of crucial equipment like boilers and pressure vessels. The durability, strength, and versatility of steel make it an indispensable material in the manufacturing industry.

- Q: How are steel coils used in the manufacturing of medical equipment?

- Steel coils are used in the manufacturing of medical equipment as they provide strength, durability, and flexibility for various components. These coils are often used in the production of surgical instruments, medical devices, and diagnostic equipment where precision and reliability are crucial.

- Q: Does the solution change, or does only the steel wool change color?

- once you upload water to anhydrous copper(II) sulphate it turns blue because of the fact that's going to become hydrous copper(II) sulphate. Then, in case you upload water greater, that's going to proceed to be blue, could be slightly darker.

- Q: What are the factors that determine the price of steel coils?

- The price of steel coils is determined by various factors. 1. Raw material costs have a direct impact on steel coil prices. The prices of iron ore and coal, which are used in steel production, can fluctuate and affect the final price of steel coils. 2. Energy costs, such as electricity and fuel, play a significant role in determining the price of steel coils. Changes in energy costs, like oil or electricity price fluctuations, can influence the overall price. 3. The demand and supply dynamics in the steel industry are crucial in determining steel coil prices. When demand is high and supply is limited, prices tend to increase. Conversely, when demand is low and supply exceeds demand, prices tend to decrease. 4. Market conditions, including economic factors and trends, can impact steel coil prices. Economic growth, industrial production, and construction activities influence the demand for steel and therefore its price. 5. Production and labor costs, including labor wages, equipment, maintenance, and transportation, contribute to the final price of steel coils. Technological advancements and production efficiency can affect these costs and, subsequently, the price. 6. Trade policies and tariffs can also affect steel coil prices. Higher import tariffs can lead to increased domestic steel prices, while lower tariffs may result in lower prices due to increased import competition. 7. Currency exchange rates can impact steel prices as it is a globally traded commodity. If the currency in which steel is priced strengthens against other currencies, it can result in higher prices for steel coils. It is important to consider that these factors are interconnected and can vary based on market conditions, geographical location, and other external factors.

- Q: How are steel coils used in the production of steel plates?

- Steel coils are a critical component in the production of steel plates. They serve as the primary raw material for manufacturing steel plates. The process begins with the production of steel coils, which are created by heating and cooling molten steel to form thin, flat strips. These coils are then processed further in a rolling mill, where they are passed through a series of rollers to reduce their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are then uncoiled and straightened. This process involves feeding the coils through a machine that removes any curvature or deformities, ensuring the strips are completely flat. The straightened coils are then cut into specific lengths to suit the required dimensions of the steel plates. After being cut, the coils undergo another crucial step known as leveling. This process involves passing the strips through a leveling machine, which eliminates any residual stress or warping that may have occurred during the production process. Leveling ensures that the steel plates have a uniform thickness and are free from any distortions, making them suitable for various applications. Once the leveling process is complete, the steel coils are finally transformed into steel plates. These plates can be further processed based on the desired end-use. They may undergo additional treatments such as heat treatment, surface finishing, or coating to enhance their strength, durability, and corrosion resistance. In summary, steel coils are the starting point for the production of steel plates. They undergo several crucial steps, including rolling, uncoiling, straightening, cutting, and leveling, to transform them into flat, uniform steel plates. These plates can then be further processed and customized for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: How are steel coils inspected for chemical composition?

- Steel coils are inspected for chemical composition through a process known as spectroscopy. Spectroscopy involves the use of a spectrometer, which is an instrument that analyzes the light emitted or absorbed by a sample to determine its chemical composition. In the case of steel coils, a small sample is usually taken from the coil and prepared for analysis. This sample is then placed in the spectrometer, which emits a beam of light onto the sample. The light interacts with the atoms and molecules in the sample, causing them to emit or absorb specific wavelengths of light. The spectrometer measures the intensity of the emitted or absorbed light at different wavelengths and creates a spectrum, which is essentially a unique fingerprint for the sample. This spectrum is then compared to a database of known spectra for different elements and compounds to determine the chemical composition of the steel. The spectroscopic analysis can identify the presence and concentration of various elements such as carbon, manganese, phosphorus, sulfur, and other trace elements that may be present in the steel. These elements play a crucial role in determining the steel's properties, strength, and suitability for different applications. Inspection for chemical composition is essential in the steel industry to ensure that the steel meets the required specifications and standards. Any deviation from the desired chemical composition can affect the steel's performance and may lead to structural failures or other defects. Overall, spectroscopy provides a highly accurate and reliable method for inspecting steel coils for their chemical composition, helping to ensure the quality and integrity of the steel products.

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- I'm afraid you have opened a can o'worms. Aluminum as a material is roughly 1/2 the weight of steel. Aluminum as a material is also roughly 1/3 the strength of steel. his means you need 3 times more aluminum to make a frame as strong as steel which makes the aluminum frame 25% heavier. That being said, well designed and more expensive aluminum frames can easily weigh less than low zoot steel. Buying a cheap bike with an aluminum frame will ALWAYS weigh more than a middle of the road bike with a steel frame. ...and THAT being said, high end steel can easily weigh less than a high quality aluminum frame... note we are talking frames in the $2000 range- just for the frame. So, based on your explanation and attendant budget of the bikes you are considering, buy the steel bike. You won't be losing or gaining anything... except saving money.

- Q: How are steel coils tested for dimensional accuracy?

- Steel coils are tested for dimensional accuracy through various methods such as measuring their width, length, thickness, and diameter using specialized tools like calipers, micrometers, or laser measurement systems. These measurements are compared against the specified tolerances provided by the manufacturer to ensure that the steel coils meet the required dimensional standards.

Send your message to us

Coated Surface Treatment Mental steel /Roofing Application Colour Steel coil/AL-Zn PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords