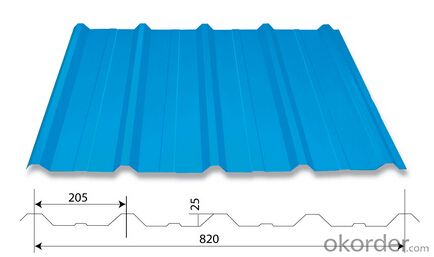

Corrugated Pressed steel plate 820

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corrugated Pressed steel plate 820

Strong concrete bond shear resistance

With Special closed-rib design, good longitudinal shear-bearing capacity, there has never been slippage between the steel bearing plate and the concrete upon closed built-up slabs within design load limit.

Excellent fire performance

The ribs of slab are completely encased in concrete, just like the cast-in reinforcement. Closed built-up slabs can completely replace the positive moment tensile reinforcement in the floor slabs, and an 1.5-hour refractory power can be achieved without need to brush fire-resistant coating

Superior section of built-up slabs

Closed built-up slabs have a higher effective height of the floor slab and a bigger combination stage to provide a more powerful positive moment resistance.

Board(Slab) end slot-type suspension system

For the use of ceilings, ceiling, plumbing installation, etc., no need of drilling or welding; during the building period, it can be moved, removed or reinstalled, according to the need.

Simple, rapid construction

It does not require any plug, with no leakage of mortar, available to shorten the construction cycle.

Even slab bottom appearance

The slab bottom is even, it is beautiful for the buildings not planned for the ceilings .

Effectively reduce the slab height

According to fire regulations and shatterproof requirements, the total thickness of the closed built-up slab is only 110-130 mm, 30-40 mm less than the opening profiled steel plate composite slab, thus getting a reduced self weight, reduced costs, and increased height.

Low cost

The reinforcements bearing the positive moment of the closed built-up slabs are replaced by the profiled steel plates, without need to brush fire-resistant coating, thus reducing the usage of reinforcements and cutting down the costs.

1.New fireproof rock wool sandwich board uses two-layer high quality colored steel sheet or other precision profiled metal plate as the panel board. After the board is rolled and shaped, stripped rock wool should be turned 90°(make its fiber perpendicular to upper and lower steel sheets), and then fire resistant bond with high strength and cohesion should be used for bonding the high quality rock wool with the metal panel together, thereby composing beautiful, smooth and rigid building board. The shaped board has excellent fire prevention, thermal insulation and environmental protection features and provides one superexcellent choice for industrial building enclosure system.

2. POILISOCYANURATE, abbreviated as PIR; composite boards developed by DUOWEI use excessive sulfone isocyanurate, so ring structure of chemical compound and higher sulfone isocyanurate index form the dense PIR, thereby making interior rigid foam more stable and have high heat resistance and flame resistance. Experiment shows that the bubble can endure 200 ℃ in a short time and can endure 160℃ in a long time.

CNBM INERNATIONAL CORPORATION

1. A group corporation enjoying a competitive edge in the field of steel structure and new building boards, was founded in 1983 with the registered capital being 126 million yuan in exporting colored steel sheet, whose headquarters is located in Zhongguancun Fengtai Science Park, Beijing.

2. In the 1980s, CNBM has achieved professional advantages in the field of building metal profiled plates, and thenceforward it rapidly grew into an integrated enterprise group combining with design, manufacturing, construction, services and international trade. It is the main provider and market leader of steel structure and new construction boards in China. CNBM COLORED STEEL PLATE SANDWICH PANEL currently has 16 branches and 10 manufacturing plants respectively in Beijing, Tianjin, Hebei, Shenyang, Harbin, Baotou and Urumqi,

whose products have been exported to over 40 countries and regions around the world.

3 Today, CNBM is now the top 500 Fortun Globe has grown as an enterprise with such honors as Famous Trademark of China, the Best General Service Provider of Steel Structure Building System of China, the Leader of China's New Energy-efficient Construction Board Industry,

4. China’s Top ONE Construction Enterprises in the Steel Structure Industry, the High and New Technology Enterprises in Beijing, the High and New Technology Enterprises in Zhongguancun. DUOWEI is the main co-compiler of 16 national standards and industrial standards, and possesses the National Qualification of Class A in Architectural General Design, the Qualification of Grade A in Steel Structure Engineering Special Design, the Special-grade Qualification of Steel Structure Manufacturing, the Qualification of Class A in Professional Contracting for Steel Structure Projects and the certificate of ISO 9001: 2008 International Quality Management System Certification.

5. CNBM benefits its cooperative partners continuously, like the building owners and investors, with exquisite technologies, high-quality

products and differentiated services. DUOWEI steel structure products featured in high-rise steel structure, space steel structure, heavy frame steel structure and light steel structure, has reached to 250 thousand tons in annual production; the annual production capacity of CNBM polyurethane energy-saving sandwich boards, new fireproof rock wool/glass fiber cotton sandwich boards has reached to 3 million square meters;

6. The annual production capacity of CNBM adjustable steel truss floor support plates and closed composite slabs is 5 million square meters; and the annual production capacity of CNBM colorful profiled steel plates has reached to 30 million square meters.

7.CNBM Group has been making successes in serving PetroChina, Aerospace China,

China Nuclear Power, China FAW, China Guodian, China CNR, China Coal and other super large enterprises, and participating in national key projects, such as Hexie locomotive, National Grand Rocket, National Large Aircraft, Aerospace Coal Gasification, etc., and the group will continuously provide customers with innovative products and high-quality engineering services.

- Q: Are steel sheets resistant to chemical spills?

- Yes, steel sheets are generally resistant to chemical spills. Steel is known for its high chemical resistance and can withstand exposure to various chemicals without corroding or reacting. However, the specific resistance depends on the type and concentration of the chemical involved.

- Q: What are the weight calculations for steel sheets?

- The weight calculations for steel sheets depend on their dimensions, thickness, and specific gravity. The formula used to calculate the weight of a steel sheet is: weight = length × width × thickness × specific gravity. The specific gravity of steel is typically around 7.85.

- Q: What are the different types of finishes available for steel sheets?

- There are several different types of finishes available for steel sheets, each offering unique properties and aesthetic appeal. Some of the most common finishes include: 1. Mill Finish: This is the standard finish that is achieved after the steel sheet has been manufactured. It has a rough, dull appearance, typically with visible surface imperfections. 2. Hot Rolled Finish: This finish is achieved by subjecting the steel sheet to high temperatures during the manufacturing process, resulting in a scaly, rough surface. It is commonly used for structural applications where appearance is not a primary concern. 3. Cold Rolled Finish: This finish is achieved by cold rolling the steel sheet, which smooths out the surface and creates a clean, matte appearance. It is commonly used for applications that require a smooth and uniform surface, such as automotive panels or appliances. 4. Galvanized Finish: This finish is achieved by applying a layer of zinc to the steel sheet through a process called galvanization. It provides excellent corrosion resistance and is commonly used in outdoor applications, such as roofing or fencing. 5. Electroplated Finish: This finish is achieved by electroplating a thin layer of metal, such as chromium or nickel, onto the steel sheet. It provides enhanced corrosion resistance, improved aesthetics, and can be available in various colors. 6. Powder-Coated Finish: This finish involves applying a dry powder coating onto the steel sheet and then curing it with heat. It provides a durable and attractive finish, with various color options available. Powder coating also offers excellent corrosion resistance. 7. Brushed Finish: This finish is achieved by brushing the surface of the steel sheet with an abrasive material, creating a distinctive brushed pattern. It is commonly used for decorative applications, such as architectural elements or kitchen appliances. 8. Polished Finish: This finish involves polishing the steel sheet to create a smooth and reflective surface. It is commonly used for decorative applications that require a high level of aesthetics, such as ornamental pieces or jewelry. Overall, the choice of finish for steel sheets depends on the specific requirements of the application, including factors such as durability, corrosion resistance, aesthetics, and cost.

- Q: What is the average lead time for manufacturing steel sheets?

- The manufacturing of steel sheets can have varying lead times based on a multitude of factors including order size and complexity, manufacturing processes utilized, and the current demand and capacity of the production facility. Generally, lead times can range from a few weeks to a few months. For smaller, standard-sized orders, the lead time is typically shorter, spanning from 2 to 6 weeks. This duration allows for the acquisition of raw materials, processing, and quality control procedures to ensure the final product meets the necessary specifications. Conversely, larger or more intricate orders necessitate longer lead times. This is because additional time is required to customize the steel sheets according to specific dimensions, finishes, or treatments. In such instances, lead times can extend to several months. External factors such as supply chain disruptions, unforeseen delays in raw material procurement, or fluctuations in demand can also impact lead times. Consequently, it is prudent to consult the manufacturer or supplier of the steel sheets to obtain an accurate estimate of the lead time based on the particular requirements of the order.

- Q: Can steel sheets be used for storage tanks?

- Yes, steel sheets can be used for storage tanks. Steel is a commonly used material for constructing storage tanks due to its strength, durability, and resistance to corrosion. Steel sheets are often welded together to form the tank's structure, providing a reliable and long-lasting storage solution for various liquids and gases.

- Q: Can steel sheets be used for automotive manufacturing?

- Yes, steel sheets can be used for automotive manufacturing. Steel sheets are commonly used in the automotive industry for various applications, including body panels, chassis components, and structural parts. Steel offers excellent strength, durability, and formability, making it a preferred material for automotive manufacturers. Additionally, steel sheets can be easily shaped and welded, allowing for efficient fabrication processes in automotive manufacturing.

- Q: How do steel sheets perform in terms of vibration resistance?

- Steel sheets generally offer good vibration resistance due to their high stiffness and density. The inherent properties of steel, such as its strong and rigid structure, enable it to dampen vibrations effectively. Steel sheets have high natural frequencies, which means they can resist a wide range of vibrations and minimize the amplification of vibrations that may occur in other materials. Additionally, steel sheets can be further enhanced with various techniques, such as adding damping materials or using special coatings, to improve their vibration resistance even more. Overall, steel sheets are considered to be a reliable choice when it comes to applications requiring vibration resistance.

- Q: Can steel sheets be galvanized?

- Yes, steel sheets can be galvanized. Galvanizing is a process of coating steel with a protective layer of zinc, which helps to prevent corrosion and extend the lifespan of the steel sheets.

- Q: How thick are steel sheets available?

- Steel sheets are available in various thicknesses, ranging from as thin as 0.4 millimeters to as thick as 150 millimeters, depending on the specific application and requirements.

- Q: Are steel sheets resistant to impact?

- Yes, steel sheets are generally resistant to impact due to their strong and durable nature.

Send your message to us

Corrugated Pressed steel plate 820

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords