Cold Rolled Stainless Steel Sheet With Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled Stainless steel sheet and hot rolled stainless steel sheet , and stainless steel plate/slab are all widely used in the field of construction and decoration field, etc.

The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

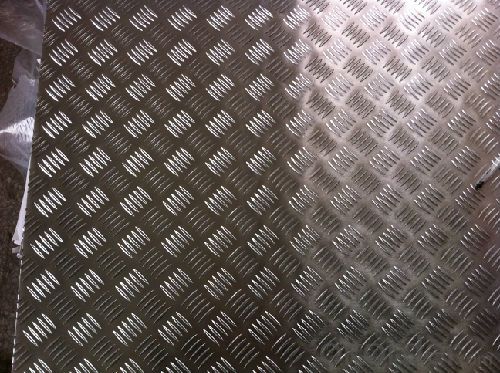

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 3 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: What is the width of the carbon steel coil and the width of the stainless steel coil, one is 1250, and the other is 1219?

- Domestic stainless steel rolling mill is generally 1219, but the design standard is 1300, so there will be flash board 1250, that is not the standard board, belonging to the flash, waste materials, many products manufacturers are also in 1219 as a reference size, product development, if the plate width will be wasted, a lot of scrap production the process, so the business order is generally around 1219 stainless steel coil.

- Q: What are the color options for stainless steel sheets?

- The color options for stainless steel sheets are typically limited to the natural silver-gray hue of stainless steel itself. However, certain surface treatments and coatings can be applied to stainless steel sheets to create different colors such as black, gold, bronze, and even vibrant shades like blue and red.

- Q: Are stainless steel sheets suitable for elevator buttons?

- Indeed, elevator buttons can be made from stainless steel sheets. The reason behind this preference for stainless steel lies in its remarkable durability, resistance to corrosion, and effortless upkeep. Given that elevator buttons are frequently pressed by countless individuals throughout the day, stainless steel can endure the strain and continuous usage without compromising its visual allure. Moreover, stainless steel boasts simple cleaning and sanitizing procedures, rendering it an excellent hygienic option for elevator buttons. In summary, stainless steel sheets represent a superb choice for elevator buttons, delivering both resilience and a stylish, contemporary look.

- Q: Are stainless steel sheets suitable for heat transfer equipment?

- Yes, stainless steel sheets are indeed suitable for heat transfer equipment. Stainless steel has excellent thermal conductivity, which allows for efficient heat transfer. It also has high corrosion resistance and can withstand high temperatures, making it a reliable choice for various heat transfer applications.

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat pieces of metal made from stainless steel, a type of alloy that contains chromium, nickel, and other elements. These sheets are highly versatile and widely used in various industries for their excellent corrosion resistance, durability, and aesthetic appeal. They are manufactured through a process called hot rolling or cold rolling, which involves passing the steel through a series of rollers to achieve the desired thickness and finish. Stainless steel sheets are commonly used for applications such as construction, automotive manufacturing, kitchenware, appliances, and architecture. They come in different grades, surface finishes, and sizes to cater to different requirements. Whether it's for decorative purposes or functional applications, stainless steel sheets offer a reliable and long-lasting solution.

- Q: How are stainless steel sheets finished?

- Stainless steel sheets are finished through various processes such as grinding, polishing, and buffing, which result in different surface textures and appearances.

- Q: What are the different types of stainless steel sheet finishes for industrial applications?

- There are several types of stainless steel sheet finishes for industrial applications, including 2B, No. 4, No. 8, BA, and brushed finishes.

- Q: What's the difference between 201 and 204 stainless steel plates? Thank you

- Price, 04 is far higher than the price of 01, according to the use of the environment, product quality requirements to choose the right material

- Q: Are stainless steel sheets resistant to scratches?

- Yes, stainless steel sheets are generally resistant to scratches. Stainless steel is known for its durability and strength, making it highly resistant to scratching or denting. However, it's important to note that no material is completely scratch-proof, and stainless steel can still develop minor scratches over time with regular use. However, these scratches are usually superficial and can often be easily removed or minimized with proper cleaning and maintenance. Additionally, the level of scratch resistance can vary depending on the grade and finish of the stainless steel sheet.

- Q: Can stainless steel sheets be custom-cut?

- Yes, stainless steel sheets can be custom-cut to fit specific sizes and dimensions. Stainless steel is a highly versatile material that can be easily manipulated and shaped according to individual requirements. Custom-cutting stainless steel sheets is a common practice in various industries, such as construction, manufacturing, and fabrication. This process ensures that the stainless steel sheets perfectly fit the intended application, whether it is for architectural purposes, machinery parts, or kitchen appliances. Professional metal fabricators or specialized service providers typically use advanced cutting techniques, such as laser cutting, waterjet cutting, or shearing, to accurately customize stainless steel sheets to the desired specifications.

Send your message to us

Cold Rolled Stainless Steel Sheet With Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords