15x300 Continuous Filament Spunbonded Nonwoven Geotextile Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Continuous Filament Spunbonded Nonwoven Geotextile

Geotextile Description

Polyester filament geotextile acupuncture non-woven geotextile, there is a polyester filament geotextile after high-speed needle acupuncture and into cloth products, do not contain chemical additives in the process of needle, also without heat treatment, is environmentally friendly building materials.

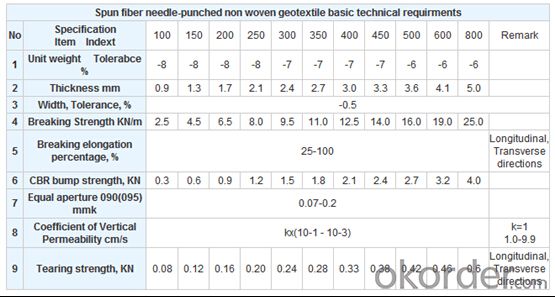

Geotextile Specification

Geotextile Property:

1. Good flexibility, resistant to corrosion, resistant to acids and alkalis, anti-oxidation.

2. Separation, filtration, drainage, reinforcement, protection, and maintenance function.

Geotextile Application:

1. Water conservancy project and hydropower project.

2. Road paving, railway.

3. Airport and port.

4. River bank protection and tunnel

5. Environmental protection, etc.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 sqm.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: What are the advantages of using geotextiles in stormwater management?

- Geotextiles offer several advantages in stormwater management. Firstly, they act as a filter, preventing fine particles and pollutants from entering the stormwater system, thus improving water quality. Secondly, geotextiles provide erosion control by stabilizing soils and preventing soil erosion during heavy rainfall events. Additionally, these materials aid in water infiltration, allowing stormwater to be absorbed into the ground instead of overwhelming drainage systems. Lastly, geotextiles are cost-effective and easy to install, making them a practical and efficient solution for stormwater management.

- Q: What are the applications of geotextiles in civil engineering?

- Geotextiles have various applications in civil engineering, including soil stabilization, erosion control, filtration, drainage, and reinforcement. They are commonly used in road construction, retaining walls, embankments, and landfills to improve the performance and durability of these structures. Geotextiles offer benefits such as increased load-bearing capacity, enhanced drainage, and reduced soil erosion, making them essential components in many civil engineering projects.

- Q: How do geotextiles help in preventing soil contamination from chemicals?

- Geotextiles help prevent soil contamination from chemicals by acting as a physical barrier between the contaminated soil and the surrounding environment. These synthetic materials are placed in soil to serve as a protective layer, preventing the migration of chemicals and pollutants. Geotextiles also aid in filtration, allowing water to flow through while trapping and retaining the harmful substances, minimizing their potential impact on the soil and groundwater.

- Q: What are the standards and specifications for geotextiles?

- The standards and specifications for geotextiles vary depending on the specific application and use of the geotextile. However, some common standards and specifications include physical properties such as tensile strength, elongation, puncture resistance, and filtration properties. Additionally, standards may also address factors like UV resistance, chemical compatibility, and installation guidelines. These standards ensure that geotextiles meet the desired performance requirements and are suitable for their intended use in various geotechnical and civil engineering applications.

- Q: GB waterproof geotextile what price

- GB waterproof geotextile details please see

- Q: Can geotextiles be used for drainage?

- Yes, geotextiles can be used for drainage. They are commonly used in various drainage applications such as road construction, retaining walls, and landfills. Geotextiles help to enhance the drainage system by allowing water to pass through while preventing the loss of soil particles. They also provide filtration and separation, ensuring optimal drainage performance.

- Q: Geogrid Specifications TGSG40-40 What does it mean?

- I tell you, TGSG40-40: two-way stretch plastic geogrid, its vertical, horizontal strength indicators are not less than 40KN, to meet the national standards. We are a professional geogrid manufacturer, you have any questions you can call: 13879 22308, also welcome you to visit the company. Thank you!

- Q: Are geotextiles resistant to fire?

- Yes, geotextiles are generally resistant to fire. They are typically made from materials that have high melting points and are designed to withstand exposure to heat and flames without catching fire or spreading flames. However, it is important to note that the level of resistance may vary depending on the specific type and composition of the geotextile.

- Q: 300g geotextile GB thickness is how much

- 2 to 2.5 mm or so. There are other questions to ask me that I am doing this industry

- Q: Can geotextiles be used in geosynthetic clay liner caps?

- Yes, geotextiles can be used in geosynthetic clay liner caps. Geotextiles are often used as a separate protective layer or as a reinforcement in geosynthetic clay liner caps to enhance their performance and provide additional benefits such as filtration, separation, and erosion control.

Send your message to us

15x300 Continuous Filament Spunbonded Nonwoven Geotextile Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords