Flat Black Aluminum Sheets - Continuous Casting Aluminium Strips for Food Cookware AA1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Continuous Casting Aluminium Strips for Food Cookware AA1060

Continuous Casting Aluminium Strips for Food Cookware AA1060 are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Continuous Casting Aluminium Strips for Food Cookware AA1060

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

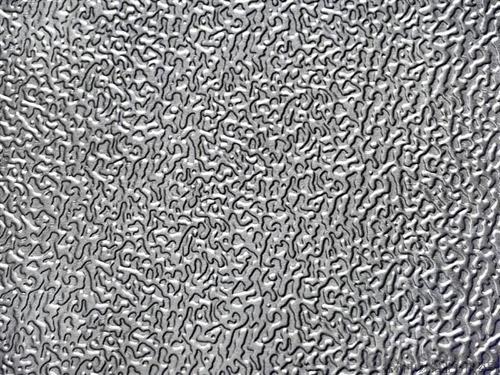

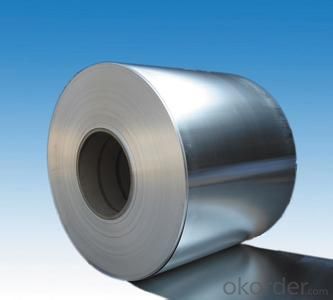

3. Image of Continuous Casting Aluminium Strips for Food Cookware AA1060

4. Product Specification of Continuous Casting Aluminium Strips for Food Cookware AA1060

| Alloy | Temper | Rolling | Thickness | Width |

| AA1060 | F | Hot Rolled | 0.2MM-2MM | 1000MM-1500MM |

5.FAQ of Continuous Casting Aluminium Strips for Food Cookware AA1060

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used for window frames?

- Indeed, window frames can be made using aluminum sheets. The utilization of aluminum for window frames is widespread because of its durability, lightweight characteristics, and ability to resist corrosion. Aluminum frames provide exceptional strength and stability and can be effortlessly tailored to suit any window size or shape. Moreover, aluminum frames necessitate minimal upkeep and can be painted or anodized to match any preferred color or finish. In summary, aluminum sheets serve as a versatile and dependable material for the construction of window frames.

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- They both hurt a lot! Wooden ones are heavier and have more density, while aluminum ones are lighter, but they can swing a lot faster. So really, they both have their things about them that make them very painful. I wouldn't recommend getting smacked with ANY baseball bat - they HURT!!!

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- This okorder ... Now for the bad news, most scrap yards DO NOT accept tabs, they try to say it's a lower grade of aluminium, which is not correct, as it is made out of the same sheet of aluminium as the can was. They just don't want to deal with it, or the people who alway's HEARD SOMEWHERE that tabs have some special value. The truth of the matter is that 1 pound of tabs (1,538 +/- tabs) is only worth about 40 cents. That's it, nothing more. Anybody who say's different is stupid, or a liar, there is no third option. Now, if you want to actually make some money, and your willing to do a little work, this is what I do. I take the tabs that i encounter in daily life, remove all damaged tabs (which are donated to McDonald's House Charities), then I sit there with a pair of needle nose pliars, and I remove that little curly thing that holds the tab to the can (which I save, and yes recycle as aluminium , over 220 pounds to date), now, count your tabs out into 1,000 count ziplock baggies. Each of these bags with 26 cents of aluminium will now sell on E-Bay for $4 plus shipping, which is $6.15 per pound. People need them for arts and crafts, I have sold literally millions on OKorder and my web site. The colored tabs are worth about 2 cents each, MONSTER and NOS tabs are worth about 5 cents each.

- Q: Can aluminum sheet be welded?

- Yes, aluminum sheet can be welded. Aluminum is a versatile metal that can be easily welded using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and resistance spot welding (RSW). However, welding aluminum requires special considerations due to its high thermal conductivity and low melting point compared to other metals. It is important to choose the appropriate welding process, filler material, and shielding gas to ensure a successful weld. Additionally, proper surface preparation, including cleaning and removing any oxide layer, is crucial for achieving a strong and durable weld in aluminum sheet.

- Q: Can aluminum sheets be used for automotive applications?

- Indeed, aluminum sheets find their utility in automotive applications. Being both lightweight and corrosion-resistant, aluminum proves to be an optimal choice for various automotive constituents. Car bodies, engine parts, wheels, and other structural components are commonly constructed using aluminum due to its desirable properties. Aluminum sheets possess an outstanding strength-to-weight ratio, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits commendable thermal conductivity, ensuring efficient heat dissipation in automotive scenarios. Consequently, the utilization of aluminum sheets in automotive production has gained substantial popularity owing to its numerous benefits.

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: when aluminum metal undergoes a combination reaction with O2(g)

- Aluminium metal combines with the oxygen from the air on heating to form aluminium oxide. The reaction can be represented using a balanced equation as 4 Al (s) + 3O2(g) = 2Al2O3(s)

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Generally, aluminum sheets exhibit resistance to corrosion from saltwater. When exposed to air or water, including saltwater, aluminum naturally develops a protective oxide layer. This layer serves as a barrier, preventing additional corrosion and safeguarding the underlying metal. Furthermore, aluminum is both lightweight and durable, making it a favored choice for numerous marine applications such as boats, shipbuilding, and offshore structures. Nevertheless, it is important to acknowledge that the level of resistance to saltwater corrosion may differ based on the specific alloy and surface treatment of the aluminum sheets. Consequently, selecting the appropriate alloy and applying protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: Is it possible to use aluminum sheets for creating personalized designs or artwork?

- <p>Yes, you can use aluminum sheets to create custom designs. Aluminum is a versatile material that can be cut, shaped, and bent to create various designs. It is lightweight, durable, and resistant to corrosion, making it suitable for both indoor and outdoor applications. You can use techniques such as laser cutting, engraving, or bending to personalize aluminum sheets for your specific needs. Additionally, aluminum can be anodized or painted to achieve different colors and finishes, further enhancing the customization options.</p>

- Q: Are aluminum sheets suitable for lightweight structures?

- Indeed, aluminum sheets prove to be a fitting choice when it comes to lightweight structures. Renowned for its low density and impressive strength-to-weight ratio, aluminum emerges as an optimal material for applications requiring reduced weight. Industries such as aerospace, automotive, and construction frequently rely on aluminum sheets due to their exceptional corrosion resistance, durability, and malleability. These properties facilitate effortless fabrication and installation. Moreover, the versatility of aluminum sheets extends to their effortless joining through diverse welding and adhesive methods, thereby bolstering their aptness for lightweight structures.

Send your message to us

Flat Black Aluminum Sheets - Continuous Casting Aluminium Strips for Food Cookware AA1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords