Steel Cuplock Scaffolding System for Concrete Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Steel Cuplock Scaffolding System for Concrete Building Construction

Name Cuplock Scaffold System Size Many sizes or as your request Main Material Q235/345 Steel Surface Treatment High Protected Painted, Powder Coating, Electric Gavenized, Hot Dip Gavenized. Color Silver, Orange, Red Certificate SGS, EN12810. Service OEM Service available MOQ 50T Payment T/T, Western Union Delivery Time 15-25 days after deposite Packing in bulk or steel pallet or as your request production capability 50 tons per day Main Market Africa, South America, the Middle East and Asia

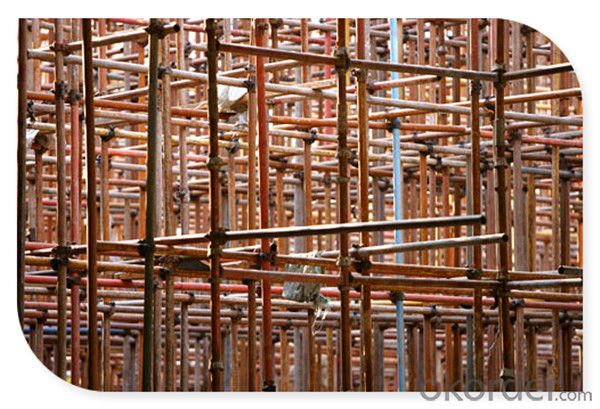

Descriptions of Steel Cuplock Scaffolding System for Concrete Building Construction

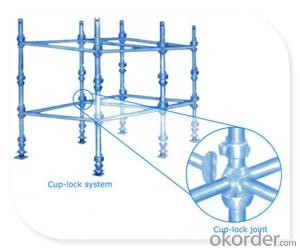

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Steel Cuplock Scaffolding System for Concrete Building Construction

1.Cuplock scaffold system is simple in structure,including top cup,bottom cup and ledger blade.

2.Quick installation of horizontals and verticals,you can easily fit the ledger blade into the cups with a hammer.

3.Cuplock scaffold system standards are made from higher quality steel tube which allow more than 58KN load per leg.

4.Cuplock scaffold system is a multi-functional scaffolding system which is suitable for all forms of access and support structures,especially used in bridege building.

5.People can fasten joint of ledgers by putting two extra ledger blades in the cups.

6.This cuplock scaffold system are interlocked by cups and ledgers which is very safe and stable steel scaffolding system.

7.This is a heavy duty scaffold system which can load about 16tons for each cuplock scaffolding system.

8.Cuplock scaffold system can be used both interior or outerior high-rise building construction project, expecially for arc shape building such as bridge, tunnel, subway, or gym building. it's multifunctional.

9.This is a galvanized cuplock scaffold system which surface is hot dip galvanized, it can keep a longer working life.

10.Gavanized cuplock scaffold system is water-proof scaffold sysem which can prevent the air and water to damage the cups and ledgers very effectively.

11.Cuplock scaffold system can be quick to errect by interting the cuplock blade into bottom cup, then swivel the top cup to fixed it.

12.Suitable for transportation and storage: Single cuplock scaffold system standard and ledger occupy less space. Wiht no extra parts.

The Measures of Steel Cuplock Scaffolding System for Concrete Building Construction

Standard: 3000mm, 2500mm, 2000mm, 1500mm, 1000mm, 500mm.

Ledger: 3000mm, 2000mm, 1780mm, 1500mm, 1000mm, 500mm.

Diagonal brace: 3000X2000mm, 1780X2000mm, 1000X1500mm, 1000X2000mm, 1500X2000mm,

Tube specification: Φ 48.3X4.0mm, φ 48.0 X3.25mm, φ 48.0 X3.0mmFAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: What issues need to pay attention to the construction of high-level scaffolding

- The use of the end of the scaffolding (including the construction of accessories) should be returned to the library, classified storage. Open dumps, the site should be smooth, good drainage, under the support pad, and covered with a sheet, accessories, parts should be stored indoors. Wuxi Dongfang scaffolding scaffolding factory products strictly according to JOD-1999 and OD15001-1205 standards, a type of mobile scaffolding scaffolding, scaffolding, roulette scaffolding, scaffolding and scaffolding accessories.

- Q: The role of the external scaffolding and the relevant provisions?

- Scaffolding outside the building in the construction of the building is an indispensable important tool for erection. Its role: first, can make the construction personnel in different parts of the operation of the high; two is to ensure the safety of construction personnel in the high altitude operation

- Q: hi guys i got my scaffold piercing a couple of days ago and it keeps bleeding on and off and there was dry blood but i removed it and its bleeding more what could i do step by step to keep total care of my piercing to get rid of all these problem please help it will really be appreciated

- leave the dry blood let it heal be patient

- Q: Which kind of scaffolding is the most convenient and time-saving?

- The advantages of the new scaffold (compared with the bowl button) are as follows:1, with sufficient mechanical strength, stiffness and stability, safe and reliable work.2, the node connection without frame degree, has the ability to self lock, installation and disassembly flexible and quick, easy to grasp, support, removal efficiency than the bowl buckle type multifunctional scaffolding about three times, can save labor, labor, save time. In the process of construction, opening and closing channels at any time.

- Q: Can you identify Scaffold Grade Aluminum tubing by looking at it.?

- The grade or type of Aluminum Alloy materials can not be identified visually because they are almost all the same in appearance. Normally these materials are marked with there Alloy number or designation like, 6061- T6, at certain intervals so that users can distinguish them.

- Q: 21M high full scaffold erection scheme

- 2 should be based on the results of the inspection to improve the construction organization design of the demolition of the order and measures, approved by the competent authorities before the implementation;3 removal of debris and ground barriers on the scaffold.4.2 removal of scaffolding, should meet the following requirements:

- Q: I know people have different pain thresholds. But I was wondering if it was more painful than a lobe piercing? It will be done with a needle and are they aloud to freeze it? Or is it not needed?

- I got my lobes pierced 5 years before my industrial so I can't compare the pain but everyone says industrial. Idk if they can freeze or not. The pain is completely tolerable.

- Q: A 67.0- painter is on a uniform 21- scaffold supported from above by ropes. There is a 3.8- pail of paint to one side. The ropes are 1m inside the scaffold on each side. The pail is 1m away from the left rope and 3m from the right rope. The scaffold is a 6m. How close to the right end can he approach safely? How close to the left end can he approach safely?

- First of all...no units, no answer. Second of all...according to OSHA (Occupation Safety and Health Administration), NO ONE can walk on a scaffold beam outside the support ropes OR SET ANY OBJECT DOWN outside the support ropes. Hence the answers for both questions are 1 meter. It doesn't matter what a calculation will yield...NO ONE can walk on the beam outside the support ropes safely. Even if a torque balance yields that it will not put the ropes in compression and buckle them...it still isn't considered to be safe by OSHA if the painter is outside the ropes.

- Q: He pushes a can over the scaffold at 15 meters and it takes 3.25 seconds for it to land.I keep doing the problem over and over. the Correct answer is 20.5 m/s, however I keep arriving to the solution of 17 m/s. I solved it by doing Vf^2 = Vi^2 + 2adwhere the initial velocity is zero and the acceleration is -g. I made my coordinate system so that down is negative in which the distance will be negative. This however, did not give me the correct answer. Am I right or is the book right?

- The initial velocity is not zero since the scaffold is moving upward when the can gets pushed over. And final velocity, vf, does not represent the speed of the scaffold (if that is what you're trying to solve). y = (vo)(t) - (1/2)gt? 15 m = (vo)(3.25 s) - (1/2)(9.81 m/s?)(3.25 s)? vo = +20.5 m/s

- Q: along with this question, -what does she think about during this time period?-how does she apprear on the scaffold? -who does she see and how does she feel?THANKS!!=]

- Read the book and find out! I think she's up on the scaffold sometime in spring, but as I said, READ it and make sure.

Send your message to us

Steel Cuplock Scaffolding System for Concrete Building Construction CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords