Constantan-type with high strength a quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Continuous use up to

...1300F (704C)

Single Exposure up to

...1600F (871C)

Good Moisture, Chemical

...And Abrasion Resistance

High Temperature Stability

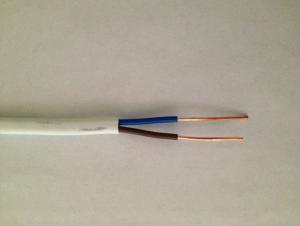

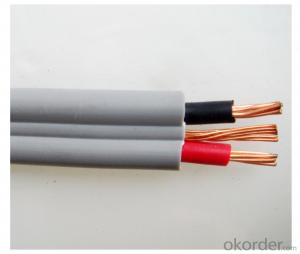

Conductor: Solid or stranded thermocouple wire per

ASTM E230 & ANSI MC96.1

Insulation: Braided fiberglass with high

Temperature impregnation*

(24 to 30 AWG Served Glass)

Construction: Parallel conductors

Jacket: Braided fiberglass with high

Temperature impregnation*

Operating temperature: +1300F (+704C) continuous

+1600F (+871C) single exposure

Limits of error: Conforms to ASTM E230, IEC 584

And ANSI MC 96.1

Shanghai Tankii Alloy Material Co., Ltd.

- Q: 16 square millimeters of wire how rough how to calculate

- Re-in charge of wiring, ordinary lighting and socket with 16 tubes (that is, the British 4 in charge), 2.5 square line is not more than 3 is appropriate; air conditioning tube should be used 20 tubes (that is, the British 6 in charge), 4 square Line is not more than 3 is appropriate, air conditioning line to be set up a separate circuit.

- Q: How do you work this out from the voltage or fuse size using a formally?

- ALL appliance come WITH a cable and wire attached, all you do is plug it in!

- Q: I saw a show about how it can affect the way you feel temperature, and light touches. There were a few cases in which the electrical wiring needed to be fixed, and that ultimately resolved the situation of the supposed paranormal. Anybody experienced this?

- Yes, the garage in my building is very weird. There's a laundry room and I go in there to wash clothes and I always feel like I'm being watched. It's not a paranormal feeling though. I don't sense any spirits down there or anything like that. The garage is pretty empty as far as feeling goes, it's mainly a space for storage, cars and trash bins. I noticed that right behind me in the ceiling are a lot of electric lines and a square box almost directly aligning with me when I am putting clothes in the wash, at which point my back is turned. When I am putting clothes in the dryer, I am out of view of that box and I don't feel watched then. It took me a while to figure it out because although I've heard of EMF's having this effect on people, I'd never experienced it for myself. For a while there I just thought it was really odd and thought that maybe I was just afraid of other tenants sneaking up on me. The feeling persists but I ignore it now. Once I determined for myself that it wasn't paranormal, I was less bothered by it.

- Q: going to roll out attic insulation between the ceiling joists. what do I do when I come across wires that go through the joists? Can I roll the insulation over the wires or should I cut it and leave the wire exposed and start the roll again on the other side of the wire?

- There are some people that shouldn't give advise if they don't know what they are talking about. Please, please don't ever cover an electrical wire with insulation. Jim W is right on! Heat will destroy electrical wire. The NEC's acceptable method of workmanship manner is to (actually) take the time and PULL the insulation under the wire.

- Q: I am putting all my lighting on a single circuit, and have a question. The main feed from the panel to the lights first goes to a double gang switch, one switch controls the lights on half of the main room in the basement, the other controls the lights in the other half of the main room in the basement. Then I need the main feed to continue to three other switches in three other rooms in the basement. Do I just wire nut the black wired and wire nut the white wires, and continue running to the next switch. So if that is the case, then am I correct in saying that in the double gang switch I will have one wire nut with the ground wires, one wire nut with 4 black wires, and one wire nut with 4 white wires? Please help with this matter, I want to do this correct, so my house doesn't burn down.By the way I am using 14/2 wire.

- Yes,this will work. The rule of thumb is to break the Black for lights and switches, and to keep the white wire pure (contiuous). I hope this helps. I know that wiring can get confusing trying to wire in more than one switch on a line, so good luck.

- Q: 3000W of the electrical use of the wire

- This is based on the current, single-phase current I = P / U = 3000/220 = 13.6A three-phase current I = P / (1.732 * U * 0.8) = 3000 / (1.732 * 380 * 0.8) = 5.69A You can choose the appropriate wire according to the standard, see below

- Q: Please guess a riddle: a beautiful ride on the wire. (Hit a plant) Rural visible

- Sorghum (pretty) should be the case The The The The Do the job. The The

- Q: I know they shouldn't be allowed to view pornography, but what about electrical wiring videos as well?If they do, and they learn how to do electrical work, would that make them want to experiment and try things at home? If they did that, they might get electrocuted.

- You are right. I think we should ban husbands and children from those videos. Nothing good comes from it.

- Q: I have a '49 ford truck, w/350 v8 Chevy engine. The fan is currently hot wired straight to the battery. How do I connect it to the ignition so the fan goes off when I shut off the engine?

- Install okorder

- Q: For example if I put a screw in the wall and it goes through an electrical wire will that screw cause electrical leaks. Another example is everytyhing in house was unplugged and shut off and power meter was still running, what could be the cause?

- yes and no, when it comes to comms gear between wired handsets, you can have a pull off or a leak if the wire gets wet, this happens with the emf field which is generated by flow of electrons. when you pull on the emf, you create an amperage draw, which can result in a leak. in a house, you have a lot of appliances that draw a small ammount even when off.if its an older meter, they run off detecting emf through magnets, an old trick was to put a magnet against the ones that spin and watch it slow down, or even reverse if the magnet is strong enough since it is providing an emf. and the screw on the wall will not cause a leak in itself, unless it hits a grounded object to make a return path. the insulation on wire is not like a pipe for water or gas, it does not prevent electricity in a low voltage setting( low voltage is 600 volts or lower) from escaping, it prevents it from hitting anything to ground out. in high voltage there is no insulation, because it will not stop the emf field. when these wires get wet they hum due to creating decently unnatural waves on the electromagnetic spectrum and cause the air to vibrate around it, this is also a slight drain. transfomers also hum due to the fact they are basically an emf generator and an emf catcher, with the catcher pulling whatever amperage is needed out of it to the facility it powers

Send your message to us

Constantan-type with high strength a quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m

- Supply Capability:

- 1000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords