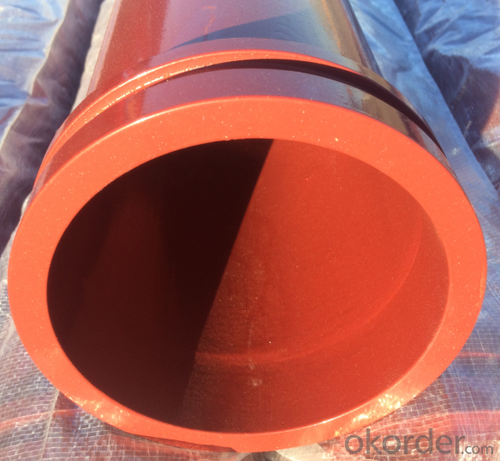

Concrete Pump Truck Parts Delivery Pipe without flange DN125 6MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

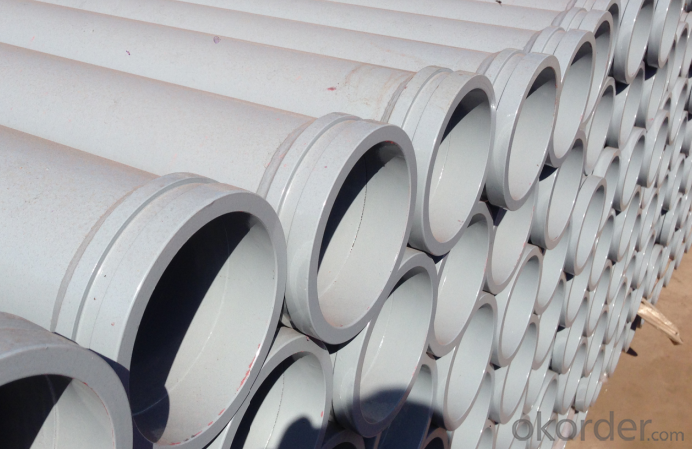

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request.

2. Service life:7000-80000 CBM Concrete.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market.

5. We can supply OEM service and can also produce according to your requirements./ OEM service available.

6. Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

Product Specifications:

Dimension: DN125

Length: 6m

Thickness: 4.1mm

Material: ST52

Weight: 83kg

Characteristics: double-ends flange

Package: Seaworthy packing or as customers’ request.

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products :

- Q: Are there any specific recommendations for the inspection and testing of concrete pump spare parts?

- Yes, there are specific recommendations for the inspection and testing of concrete pump spare parts. It is important to regularly inspect and test the spare parts to ensure their functionality, durability, and safety. Some recommendations include conducting visual inspections for any signs of wear, corrosion, or damage, performing pressure tests to check for leaks or weak spots, and checking the dimensions and specifications to ensure proper fit and compatibility. Additionally, following the manufacturer's guidelines and consulting with experts in the field can provide further guidance on specific inspection and testing procedures for concrete pump spare parts.

- Q: Are there any specific guidelines for the installation of sensors or transmitters in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of sensors or transmitters in concrete pump spare parts. These guidelines typically include ensuring proper alignment and positioning of the sensors or transmitters, securely mounting them to prevent movement or damage, and following manufacturer instructions for wiring and connection. It is important to adhere to these guidelines to ensure accurate and reliable operation of the sensors or transmitters in concrete pump spare parts.

- Q: What is the name of the pump for concrete transportation?

- The power of the concrete pump truck engine power is transmitted to the hydraulic pump or rear axle through the power transfer case, push the piston to drive the hydraulic pump concrete pump. Then use the pump cloth on the rod and delivery pipe, the concrete delivery to a certain height and distance.

- Q: How often should concrete pump pressure gauges be inspected and replaced?

- Regular inspections of concrete pump pressure gauges are necessary to ensure they are accurate and functioning properly. The frequency of inspections and replacements may vary depending on the specific conditions and usage of the pump. However, it is generally recommended to inspect and replace pressure gauges at least once a year or after every 500 pumping hours, whichever comes first. This regular schedule helps prevent any potential accuracy or functionality issues that could impact the safety and efficiency of the pumping operations. It is also essential to adhere to the manufacturer's recommendations and guidelines for pressure gauge maintenance and replacement to maintain optimal performance and longevity.

- Q: How often should a concrete pump spectacle plate be replaced?

- The frequency at which a concrete pump spectacle plate should be replaced largely depends on various factors such as the type of concrete being pumped, the intensity and duration of usage, and the overall maintenance and care given to the pump. However, as a general guideline, it is recommended to inspect and assess the condition of the spectacle plate regularly and replace it if any signs of wear, damage, or deformation are noticed. In some cases, this might be needed every few months, while in others it could be extended to a year or more. It is crucial to follow the manufacturer's recommendations and consult with industry professionals to determine the appropriate replacement schedule for the spectacle plate in order to maintain the optimal functioning and safety of the concrete pump.

- Q: Can I get spare parts for both concrete pumps with and without boom control systems?

- Yes, you can typically get spare parts for both concrete pumps with and without boom control systems. Many manufacturers and suppliers of concrete pumps offer a wide range of spare parts to meet the needs of different types of pumps. Whether it's for a pump with a boom control system or one without, you should be able to find the necessary spare parts from reputable suppliers. It is recommended to contact the manufacturer or supplier directly to inquire about the availability and compatibility of spare parts for your specific concrete pump model.

- Q: How long does it take to receive concrete pump spare parts after ordering?

- The delivery time for concrete pump spare parts can differ based on various factors. It is crucial to acknowledge that the availability of the specific parts you require and the location of the supplier can have a significant impact on the time it takes for them to arrive. Generally, if the spare parts are readily available and in stock, you can expect to receive them within a few days to a week. This assumes that the supplier has an efficient order processing system and prompt shipping arrangements. However, if the spare parts are not in stock, the duration to receive them may be longer. In such instances, the supplier might need to order the parts from a manufacturer or source them from a distributor. This could result in additional lead time for delivery, ranging from a few weeks to several months, depending on availability and the sourcing process. To obtain an estimate of the delivery time, it is advisable to consult with the supplier or manufacturer before placing your order. Additionally, factors like the supplier's location, transportation mode, and potential customs or logistics delays should be taken into consideration. If you require the spare parts urgently, some suppliers may offer expedited shipping options for an extra cost. This can be advantageous in expediting the delivery process. In conclusion, the time it takes to receive concrete pump spare parts after ordering can vary. However, by being proactive, maintaining communication with the supplier, and planning ahead, you can help ensure a smoother and quicker delivery process.

- Q: How can a faulty accumulator affect the pumping efficiency?

- A faulty accumulator can significantly affect the pumping efficiency in a variety of ways. Firstly, an accumulator is a device that stores energy in the form of pressurized fluid. It helps regulate the flow of fluid in a hydraulic system and provides additional power when needed. If the accumulator is faulty, it may not be able to store or release fluid properly, leading to an imbalance in the hydraulic system. This imbalance can cause fluctuations in pressure, flow rate, and overall system performance, resulting in reduced pumping efficiency. Secondly, a faulty accumulator can lead to increased wear and tear on the pump. When the accumulator fails to regulate the pressure properly, it can cause the pump to work harder and operate outside its normal operating range. This additional stress on the pump can lead to premature failure, decreased lifespan, and increased maintenance costs. Ultimately, this affects the pumping efficiency as the pump may not be able to deliver the desired flow rate and pressure due to its compromised condition. Furthermore, a faulty accumulator may result in unstable or inconsistent flow rates. As the accumulator is responsible for maintaining a steady flow of fluid, any malfunction can disrupt this flow pattern. This inconsistency in flow can lead to inefficiencies in the pumping system, such as increased energy consumption, reduced output, and inadequate operation of downstream components. Lastly, a faulty accumulator can impact the overall system response time. Accumulators play a crucial role in providing quick response and compensating for sudden changes in demand. If the accumulator fails to function properly, the system may experience delays in responding to load changes, leading to slower operation, reduced productivity, and potential safety hazards. In conclusion, a faulty accumulator can have a detrimental impact on pumping efficiency. It can cause imbalances in the hydraulic system, increase wear on the pump, result in unstable flow rates, and decrease overall system response time. Regular maintenance, inspection, and timely repair or replacement of faulty accumulators are essential to ensure optimal pumping efficiency and prevent potential system failures.

- Q: What are the safety measures to consider while replacing concrete pump spare parts?

- When replacing concrete pump spare parts, there are several safety measures that should be considered to ensure the safety of the workers and the overall success of the replacement process. 1. Lockout/Tagout: Before starting any maintenance or replacement work, it is crucial to follow proper lockout/tagout procedures. This involves isolating the equipment from its power source and placing lockout devices to prevent accidental startup. This ensures that the equipment cannot be operated while replacement work is being carried out. 2. Personal Protective Equipment (PPE): Workers involved in the replacement process should wear appropriate PPE such as safety goggles, gloves, hard hats, and steel-toed boots. This protects them from potential hazards like flying debris, falling objects, or accidental contact with sharp edges. 3. Equipment Inspection: Before commencing the replacement, the equipment should be thoroughly inspected to identify any potential hazards or defects. This includes checking for damaged or worn-out parts, loose connections, or any signs of deterioration. If any issues are found, they should be resolved or repaired before proceeding with the replacement. 4. Proper Lifting Techniques: Concrete pump spare parts can be heavy and bulky, so it is essential to use proper lifting techniques to prevent musculoskeletal injuries. Workers should be trained on lifting techniques and should use mechanical aids like cranes, hoists, or forklifts when necessary. Additionally, team lifting should be employed when dealing with heavy or awkwardly shaped parts. 5. Secure Work Area: The work area should be properly secured to prevent unauthorized access and ensure the safety of workers. Barricades or caution tape can be used to cordon off the area and warn others of the ongoing replacement work. Adequate lighting should also be provided to ensure clear visibility. 6. Proper Tools and Equipment: Using the right tools and equipment is crucial for safe and efficient replacement work. Workers should be trained on the proper use of tools and ensure that they are in good working condition. Using damaged or faulty tools can lead to accidents or improper installation of the spare parts. 7. Follow Manufacturer's Instructions: It is important to follow the manufacturer's instructions and guidelines for replacing concrete pump spare parts. This includes understanding the correct sequence of steps, torque requirements, and any special precautions that need to be taken. Deviating from the manufacturer's instructions can compromise the safety and performance of the equipment. By following these safety measures, the risk of accidents, injuries, or equipment damage can be minimized during the replacement of concrete pump spare parts. It is crucial to prioritize safety at all times and ensure that all workers involved are properly trained and equipped to carry out the replacement work.

- Q: Can I use alternative materials for concrete pump spare parts?

- Yes, alternative materials can be used for concrete pump spare parts. However, it is important to ensure that these materials meet the required specifications and standards for durability, strength, and compatibility with the concrete pumping system. Additionally, it is advisable to consult with professionals or manufacturers to ensure the safe and efficient functioning of the equipment.

Send your message to us

Concrete Pump Truck Parts Delivery Pipe without flange DN125 6MTR Thick 4.1MM ST52

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords