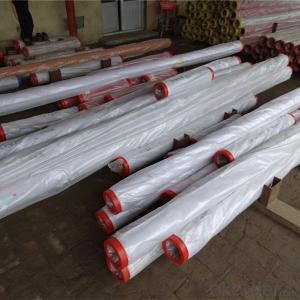

Concrete Pump Pipeline

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Size: DN125 133mm*4.5mm*3000mm/ 140mm*7.0mm*3000mm

Material: ST52, 45Mn2, Double-Wall

Flange:SK(Putzmeister-Putzmeister)/ZX(Schwing-Putzmeister)/ FM(Schwing-Schwing) Flanges

Other products:

1) Putzmeister/ Schwing/ Zoomlion/ SermacRam Pistons

2) Putzmeister/ IHI/ Kyokuto/ Zoomlion/Sany Seperated Piston

3) Wear-resisting board and Cuts ink

4) Coupling and seal ring for Putzmeister,Schwing, Sany

5) Rubber hose

6) Cleaning seriesand others- Q: How often should concrete pump hydraulic filters be inspected and replaced?

- Concrete pump hydraulic filters should be inspected on a regular basis, ideally at least once every three months. However, the frequency of inspection and replacement may vary depending on the specific conditions and usage of the concrete pump. If the pump is operating in particularly harsh environments or is being used extensively, more frequent inspections and replacements may be necessary. It is important to monitor the condition of the hydraulic filters closely and replace them whenever they become clogged, damaged or worn out. Neglecting to inspect and replace the filters as needed can result in decreased performance and efficiency of the concrete pump, as well as potential damage to the hydraulic system.

- Q: Can concrete pump spare parts be painted or coated for increased durability?

- Concrete pump spare parts can achieve greater durability by undergoing painting or coating. This protective measure shields them from corrosion, wear, and other types of harm. Applying a layer of paint or coating enhances their resistance against harsh environmental conditions, chemicals, and moisture. Furthermore, certain paints or coatings can provide extra advantages like heat resistance or non-stick properties, further bolstering the spare parts' durability and performance. It is crucial to utilize appropriate paints or coatings that are specifically formulated for the materials and conditions the spare parts will encounter, guaranteeing optimal adhesion and longevity.

- Q: Are there any specific guidelines for the installation of control valves or solenoids in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of control valves or solenoids in concrete pump spare parts. These guidelines typically include proper alignment, mounting, and connection procedures to ensure optimal performance and longevity of the components. Additionally, it is important to follow manufacturer's instructions and recommendations for the specific model of control valve or solenoid being installed.

- Q: What is the purpose of a concrete pump remote control battery?

- The primary function of a battery for a concrete pump remote control is to supply power and mobility to the remote control device that operates the concrete pump. By using the remote control, the operator can conveniently control the movements and functions of the concrete pump from a distance, eliminating the need to physically be at the pump location. The battery provides the required electrical energy to the remote control, enabling it to transmit wireless signals and commands to the concrete pump. This grants the operator the freedom to move around the construction site while still maintaining complete control over the concrete pump. Additionally, the battery ensures uninterrupted operation of the remote control, guaranteeing efficient and precise control over the concrete pump's functions.

- Q: How can a faulty agitator motor affect the concrete mixing process?

- The concrete mixing process can be significantly affected by a faulty agitator motor in several ways. To begin with, the rotation of the mixing drum, which is crucial for thoroughly blending all the ingredients in the concrete mix, is the responsibility of the agitator motor. If the motor is not functioning properly or is faulty, it can lead to inadequate mixing. This can cause inconsistencies in the concrete mixture, with certain portions being over-mixed while others are under-mixed. Consequently, the concrete may not achieve the desired level of strength, durability, or uniformity. Additionally, a faulty motor can cause irregular or insufficient agitation, resulting in the formation of lumps or clumps in the concrete mix. These lumps can have a negative impact on the quality of the final product as they can create weak spots or air pockets within the concrete. Moreover, the presence of lumps can compromise the overall workability of the mix, making it more challenging to handle and place. This, in turn, can affect the efficiency and productivity of the construction project. Moreover, an uneven distribution of materials within the mixing drum can occur due to a faulty agitator motor. This can cause variations in the proportions of aggregates, cement, water, and additives, all of which are crucial for achieving the desired properties of the concrete. Inconsistent material distribution can result in concrete with inadequate compressive strength, reduced durability, and increased susceptibility to cracking or other forms of damage. Lastly, a malfunctioning agitator motor can lead to increased mixing time as it may take longer to achieve the desired level of homogeneity in the concrete mix. This can have an impact on the overall productivity of the concrete mixing process, resulting in delays in construction schedules and increased costs. In summary, a faulty agitator motor can have a significant impact on the concrete mixing process. It can lead to inadequate mixing, the formation of lumps, uneven material distribution, and increased mixing time. All these factors can contribute to a decrease in the quality of the final concrete product, compromising its strength, durability, workability, and overall performance.

- Q: What is the importance of a good quality concrete pump seal?

- There are several reasons why a high-quality concrete pump seal is of utmost importance. Firstly, it guarantees the efficient and dependable operation of the concrete pump. The seal's main responsibility is to prevent any leakage or loss of pressure during the pumping process, which can cause delays, inefficiencies, and even damage to the pump itself. Furthermore, a top-notch seal helps to maintain the integrity of the concrete being pumped. Concrete is composed of various materials, including water, cement, aggregates, and additives. To achieve the desired strength and durability, it is essential that the concrete remains in its optimal state without any contamination or dilution. A superior seal effectively blocks any external elements, such as water or air, from entering the pumping system and affecting the composition of the concrete. Moreover, a reliable seal contributes to the safety of the pumping operation. Construction sites often utilize concrete pumps, where workers and equipment are present. Any failure or malfunction of the seal can result in unexpected incidents, injuries, or damage to property. Therefore, investing in a high-quality seal provides peace of mind and reduces the risk of accidents. Lastly, investing in a top-quality concrete pump seal can lead to significant time and cost savings in the long run. A durable and efficient seal minimizes the need for frequent replacements or repairs, reducing maintenance costs and downtime. It also ensures a smooth and uninterrupted pumping process, allowing construction projects to be completed more efficiently and on schedule. In conclusion, prioritizing the selection and installation of a reliable concrete pump seal is crucial for ensuring the efficient operation, integrity of the concrete, safety, and cost-effectiveness of a pumping project. Therefore, it is essential to give utmost importance to choosing a high-quality seal to guarantee the success and longevity of concrete pumping projects.

- Q: How can a faulty battery affect the operation of the pump?

- The operation of a pump can be significantly affected by a faulty battery. Firstly, inadequate power supply from a faulty battery can lead to slow or weak pumping action. This can result in the pump's inability to generate the required pressure or flow rate, causing inefficient or ineffective operation. Moreover, intermittent power supply caused by a faulty battery can cause inconsistent pumping action, with the pump starting and stopping unpredictably. These interruptions can create inefficiencies, diminish the pump's performance, and potentially harm the equipment or system being operated. Furthermore, a faulty battery may have a limited charge retention capacity. This can restrict the pump's operating time, necessitating frequent recharging or battery replacement. In situations where continuous or prolonged pump usage is necessary, a faulty battery can disrupt operations, resulting in downtime and reduced productivity. Additionally, the overall lifespan of the pump can be affected by a faulty battery. If the battery fails to consistently provide the required power, the pump may experience strain or excessive wear, potentially shortening its operational life. In conclusion, a faulty battery can have numerous unfavorable effects on the operation of a pump, including reduced performance, inconsistent pumping action, limited operating time, potential damage, and decreased equipment lifespan. It is crucial to conduct regular maintenance and promptly replace faulty batteries to ensure optimum pump performance and longevity.

- Q: What are the potential risks associated with the installation and replacement of concrete pump spare parts?

- The potential risks associated with the installation and replacement of concrete pump spare parts include: 1. Safety hazards: Improper installation or replacement of spare parts can lead to accidents and injuries, as concrete pumps involve heavy machinery and high-pressure systems. Inadequate training or lack of knowledge can result in mishandling of equipment, leading to accidents for both the operators and nearby personnel. 2. Equipment damage: If the spare parts are not installed correctly, it can cause damage to the concrete pump or other components. This may result in costly repairs and downtime for the equipment, impacting productivity and project timelines. 3. Performance issues: Using incorrect or low-quality spare parts can affect the overall performance and efficiency of the concrete pump. It may result in reduced pumping capacity, increased wear and tear, and decreased reliability, compromising the quality of the concrete being pumped. 4. Warranty and liability concerns: Installing unauthorized or incompatible spare parts can void the manufacturer's warranty, leaving the responsibility for repairs and maintenance solely on the user. In case of any accidents or damages caused by faulty installation, the liability may fall on the individuals or companies responsible for the installation or replacement. To mitigate these risks, it is crucial to ensure proper training and certification for the personnel involved in the installation and replacement of concrete pump spare parts. Adhering to manufacturer guidelines, using genuine spare parts, and regularly inspecting and maintaining the equipment can also minimize potential risks and ensure safe and efficient operations.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Yes, spare parts for concrete pump boom arms and pipes are available. Many manufacturers and suppliers offer a wide range of spare parts specifically designed for concrete pump boom arms and pipes. These spare parts can be easily found and purchased from authorized dealers or online stores. It is important to ensure that you provide accurate specifications and details of your concrete pump model to find the correct spare parts for replacement or repair.

- Q: How does the concrete pump work?

- Pump in place should be flat and solid, without obstacles around, no overhead transmission line. The pump shall not be parked on the slope.

Send your message to us

Concrete Pump Pipeline

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords