colored steel plate3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Model Number: | Type: | |||

| Technique: | Surface Treatment: | Application: | |||

| Material: | Certificate: | Design: | |||

| galvanized steel coil: | galvanized steel sheet: |

Packaging & Delivery

| Packaging Detail: | Naked package or loose package for steel structure |

| Delivery Detail: | According to customers' requirements & our actual producing pla n |

Specifications

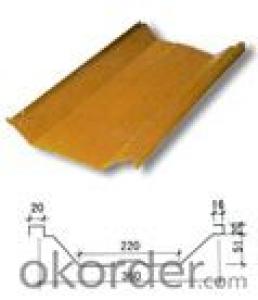

price mild steel sheet:

1. Strong and reliable Galvanized Steel Sheet

2. Antiseismic

3.Meeting different requests

Commodity | price mild steel sheet |

Thickness: | 4mm-120mm |

Width | 1500mm-3600mm |

Length | Random length as your request |

Technique | Hot Rolled and Cold Rolled |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045 |

Surface Treatment | Galvanized |

Application | Construction filed, ship building, chemical industry, food processing,etc. |

MOQ | 5 tons |

Supply Ability | 3000 tons |

Delivery | Within 7-15 days after confirmation |

Packaging | In standard export packing or as your request. |

Payment | L\C or T/T |

- Q: What are the different edge treatments for steel sheets?

- There are several different edge treatments that can be applied to steel sheets depending on the desired functionality and aesthetics. Some of the common edge treatments for steel sheets include: 1. Deburring: This process involves removing any burrs or sharp edges that may have formed during the manufacturing process. Deburring is done to improve safety and prevent injuries during handling and installation. 2. Beveling: Beveling is the process of creating a sloping edge on the steel sheet. It is often done to facilitate welding or joining of multiple sheets together. Beveled edges provide a smooth transition and increase the strength of the joint. 3. Chamfering: Similar to beveling, chamfering involves creating a beveled edge on the steel sheet. However, chamfering is primarily done for aesthetic purposes to provide a finished and polished look to the edges. 4. Hemming: Hemming is a technique used to bend the edge of a steel sheet back onto itself. It is commonly used in automotive and appliance industries to create a safe and smooth edge that eliminates the need for additional finishing or edge protection. 5. Rolled edges: Rolled edges are achieved by bending the edge of the steel sheet in a curved or rounded shape. This type of edge treatment is often employed to enhance structural integrity, reduce the risk of injury, and improve the overall appearance of the sheet. 6. V-grooving: V-grooving is a process of cutting a V-shaped groove along the edge of the steel sheet. This treatment is commonly used for decorative purposes or to create a clean and precise joint when multiple sheets are being joined together. 7. Flanging: Flanging involves bending or folding the edge of the steel sheet at a specific angle. This treatment is often used to increase rigidity and strength along the edge, especially in applications where the sheet needs to support weight or resist bending. Each of these edge treatments serves a specific purpose and can be selected based on the specific requirements of the project. It is important to consider factors such as functionality, safety, aesthetics, and ease of fabrication when choosing the appropriate edge treatment for steel sheets.

- Q: Can steel sheets be used for solar panel structures?

- Yes, steel sheets can be used for solar panel structures. Steel is a popular choice for constructing solar panel structures due to its strength, durability, and versatility. Steel sheets can be easily fabricated and shaped to meet specific design requirements, making them suitable for various types of solar panel installations. Additionally, steel has excellent load-bearing capabilities, which is crucial for supporting the weight of solar panels. It is also resistant to corrosion and can withstand harsh weather conditions, making it a reliable material for long-term use in outdoor settings. Overall, the use of steel sheets for solar panel structures is a practical and cost-effective solution.

- Q: Can steel sheets be used in architectural applications?

- Yes, steel sheets can be used in architectural applications. Steel sheets are versatile, durable, and offer structural integrity, making them suitable for various architectural uses such as roofing, cladding, and facades. Additionally, steel sheets can be easily shaped, allowing for creative and unique designs in architectural projects.

- Q: What are the advantages of using steel sheets in automotive manufacturing?

- There are several advantages of using steel sheets in automotive manufacturing. Firstly, steel sheets provide high strength and durability, making them ideal for withstanding the harsh conditions and stresses experienced by vehicles on the road. This strength allows for safer and more reliable vehicles, as steel sheets provide a strong protective structure that can absorb impact energy in the event of a collision. Secondly, steel sheets offer excellent formability, which means they can be easily shaped and molded into various complex designs required for automotive parts. This versatility allows for the creation of intricate and precise components, ensuring a perfect fit and optimal performance. Additionally, steel sheets have good corrosion resistance properties, which is crucial for automotive applications. Vehicles are subjected to various environmental factors such as moisture, salt, and chemicals, which can lead to rust and corrosion. By using steel sheets with protective coatings, manufacturers can ensure that their vehicles have a longer lifespan and maintain their aesthetic appeal. Moreover, steel sheets are readily available and cost-effective compared to other materials used in automotive manufacturing. Steel is a widely used material in various industries, which means there is a well-established supply chain for steel sheets. This availability not only guarantees a consistent supply for automotive manufacturers but also helps keep production costs manageable. Lastly, steel sheets provide excellent thermal conductivity, which is essential for heat dissipation in automotive applications. Vehicles generate a significant amount of heat, especially in the engine and exhaust systems. Steel sheets help in efficiently transferring and dissipating this heat, preventing overheating and ensuring optimal performance. In conclusion, the advantages of using steel sheets in automotive manufacturing include high strength and durability, excellent formability, good corrosion resistance properties, cost-effectiveness, and efficient heat dissipation. These factors make steel sheets a preferred choice for producing safe, reliable, and long-lasting vehicles.

- Q: Are steel sheets fire resistant?

- Yes, steel sheets are fire resistant as they have a high melting point and do not contribute to the spread of fire.

- Q: Can steel sheets be used for heat exchangers or boilers?

- Yes, steel sheets can be used for heat exchangers or boilers. Steel is a commonly used material in the construction of heat exchangers and boilers due to its high strength, durability, and resistance to corrosion at high temperatures. Additionally, steel sheets can be easily formed and welded to create the required shapes and structures for efficient heat transfer.

- Q: Can steel sheets be used for storage shelves?

- Yes, steel sheets can be used for storage shelves. Steel is a strong and durable material that can withstand heavy loads, making it suitable for storage shelving systems. Steel sheets can provide a sturdy platform to store items and can be easily customized to fit the desired dimensions and specifications.

- Q: Can the steel sheets be easily folded or creased?

- It is not possible to easily fold or crease steel sheets. Steel, being a robust and inflexible material, demands considerable force for bending or creasing. Its durability and resistance to deformation make it a popular choice in construction and manufacturing. Nevertheless, if the steel sheets are sufficiently thin, they might have enough malleability to be bent or creased by utilizing suitable tools and techniques.

- Q: What are the common thicknesses for hot-rolled steel sheets?

- The common thicknesses for hot-rolled steel sheets range from 1.6mm to 20mm, with some variations depending on specific industry requirements and applications.

- Q: What are the different coating options for steel sheets (powder coating, paint, etc.)?

- Steel sheets have a variety of coating options that each have their own unique benefits and characteristics. Some commonly used coating options include: 1. Powder coating: Dry powder coating material is applied to the steel sheet and then cured under heat to create a protective layer. This coating offers excellent durability, corrosion resistance, and aesthetic appeal. It is also environmentally friendly as it does not contain solvents or VOCs. 2. Paint: Liquid paint is applied to the surface of the steel sheet and dries to form a protective layer. Paint coatings come in a wide range of colors and finishes, making them suitable for different applications. However, they may require regular maintenance and can chip or peel. 3. Galvanizing: Galvanizing is a popular method for coating steel sheets, particularly when corrosion resistance is important. A layer of zinc is applied to the steel surface through a hot-dip process, creating a protective barrier against corrosion and rust. Galvanized coatings are highly durable and long-lasting. 4. Epoxy coatings: Epoxy coatings are known for their excellent chemical resistance and adhesion properties. They provide a tough and durable finish that protects steel sheets from corrosion, chemicals, and abrasion. Epoxy coatings are commonly used in industrial settings with harsh conditions. 5. Chromate conversion coatings: Chromate conversion coatings are applied to steel sheets to enhance their corrosion resistance and improve paint adhesion. These coatings are usually thin and translucent, giving a clear or slightly yellowish appearance. They are often used as a pre-treatment before painting or powder coating. 6. Ceramic coatings: Ceramic coatings offer exceptional heat resistance and durability. They are commonly used in high-temperature applications such as exhaust systems or industrial ovens. Ceramic coatings can withstand extreme temperatures, corrosion, and abrasion, making them ideal for demanding environments. There are many other coating options available for steel sheets. The choice of coating will depend on factors such as the intended application, desired appearance, environmental conditions, and budget. Seeking advice from a coating specialist or manufacturer can help determine the most suitable option for specific requirements.

Send your message to us

colored steel plate3

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords