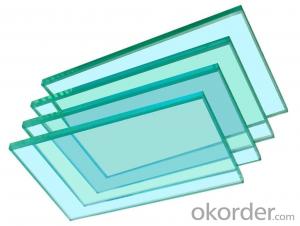

Colored Patterned Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Colored Patterned Glass is a kind of decorative translucent flat glass with embossed patterns on one or both surfaces. With the special properties of decorations, patterned glass can fully allow the light to pass through and on the other hand it can limit or prevent a clear view effectively, leading to a good "secret" result and a beautiful decorative effect.

Features of Colored Patterned Glass:

1. Diversified and colorful patterns including Karatachi, Flora, Mistlite, Nashiji, Kasumi, Chinchilla, Moran, Aqualite, Masterlite, Millennium, Raindown, etc.

2. Distinctive and original design.

3. Stereoscopic effects and never-fading patterns.

4. Easy to be processed (cutted, ground, drilled, tempered, laminated, screen-printed, etc.)

Colors for you to choose from:

dark green, Euro bronze, dark blue, Euro grey, French green, ocean blue,etc.

Specifications of Colored Patterned Glass:

Thickness: 3-5.5mm

Size: customized size

Applications of Color Patterned Glass:

Patterned Glass is widely used in all kinds of public and private places, such as offices, meeting rooms, hotels, hospitals, gymnasiums, bathrooms, washrooms, etc. It can also be applied in inlaid doors, glass furniture, shower rooms, colored crystal glass, glass partitions, bathroom doors and windows and other areas.

- Q: What kind of raw materials should be used in making FRP?

- The glass steel base material is a physical and chemical change of reinforcing material coated and firmly bonded component materials. Glass steel base material made of synthetic resin and auxiliary materials, wherein the synthetic resin is the main component. Matrix materials in FRP is the load transfer between fibers, and the load balancing. The properties of the matrix materials, such as corrosion resistance, heat resistance, directly affect the performance of FRP. Glass steel process determines the forming process of its choice.

- Q: What kind of glass is alkali free high borosilicate?

- With low density, high chemical durability, and excellent thermal stability, it also has the surface clean, widely used in TFT-LCD LCD glass substrate, excellent flatness characteristics of up to 92% of the visible light transmittance, and excellent alkali precipitation, widely used in optical coating industry, semiconductor industry.

- Q: Not man-made destruction, why toughened glass suddenly broken?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.It blew the concept of rate, the national standard of our country only glass project on the wall, I do not know whether the other foreign industry to use the toughened glass also has detailed provisions.

- Q: Raw material, processing method and ratio of glass fiber reinforced plastic

- Raw material:Glass fiber reinforced plastics (FRP), also known as GFRP, that is, fiber reinforced plastics, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastics made from glass fiber or its products are referred to as glass fiber reinforced plastics or glass fiber reinforced plastics.

- Q: Aluminum alloy window glass tape, how fast loading?

- The above two methods can only use single material, that is dry material or wet material. If the wet material is used, the first side is fixed and the other side is injected with glue and then injected onto the side. Both the inner mounting method and the outboard mounting method are best for both sides using wet material. The watertight and air tightness and the best effect of glial sickness, it is best to use silicone sealant for good. For ordinary simple aluminum alloy doors and windows, the use of single glass, fixed glass, both inside and outside the use of dry materials. For the Aluminum Alloy windows advanced commonly used sandwich or hollow glass, glass raw materials used by the heat absorbing glass processing or colored glass, glass were used for fixing the wet material or mixed material.

- Q: What material can not be sprayed on the glass?

- 1.. First spray the glass and then stick it on the outside with a transparent adhesive tape..2. uses the special printing ink for the glass product, 3. uses the glass glue to adjust the soluble pigment and the dye toner. 4. go to the print shop and do the writing, then glue it on. I hope my answer will be of some help to you

- Q: What's the price of 0.85mm thick plexiglass, please?

- Import plate material is better, about 900, but the price is more expensive, generally do not consider adopting, unless their own customers request, and canAt an accepted price.

- Q: What kind of material is made of automobile glass?

- Ordinary glass breaks can be irregular chunks

- Q: What are the ingredients of photovoltaic solar glass? What's the function of each?

- Finally, the combination of carbon and Glauber's salt, the two combination, the main role is to act as a clarifier to exclude the bubbles in the glass, the glass bubble as little as possible, to improve the glass transmission rate.

- Q: What's the difference between three kinds of glass fiber board, epoxy board and FR4 board?

- FR4 is the pure epoxy board of NEMA standard. The normal color should be dark green. This is the color of epoxy. There are also yellow, generally called yellow FR4 called yellow material, white (green) called white material.FR4 is more expensive than epoxy board and fiberglass board cannot confirm the price.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2010 |

| Annual Output Value | Above US$ 1 Million |

| Main Markets | Domestic Market Patterned Glass, Float Glass, Sheet Glass, Mirror 95.80 Southeast Asia Float Glass, Sheet Glass 0.15 Africa Mirror 0.02 Eastern Asia Patterned Glass 2.20 South Asia Patterned Glass, Float Glass 1.83 |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 2 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Colored Patterned Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100m2 m²

- Supply Capability:

- 10000m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords