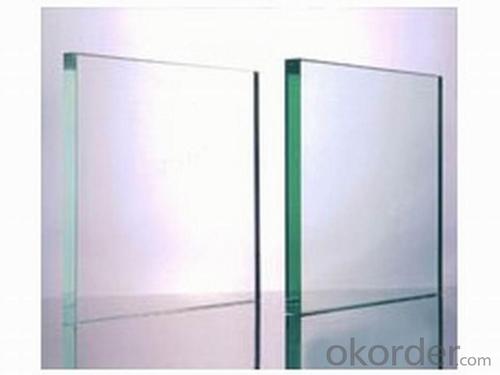

Clear Heat Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

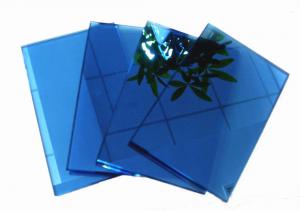

Heat-Reflective Coating Glass, also called Solar Control Coating Glass, is a kind of coated glass which has a specific coating deposited by online CVD (Chemical Vapor Deposition) or offline PVD (Physical Vapor Deposition), making the optical performances of the glass change and producing the required reflective color.

Features of Clear Heat Reflective Coated Glass:

1. Effectively limit the incident amount/incidence of the solar radiation with obvious shading effect.

2. Have a good view-obscured function for indoor objects and building components.

3. Save energy and reduce the running expenses of air conditioners.

4. Have a good decorative effect for the external walls of buildings.

5. Have a fine view-shielding function for indoor objects and construction components.

6. Designed for single use or composite use into coated laminated glass, coated tempered glass, coated insulating glass or other coated composite glass.

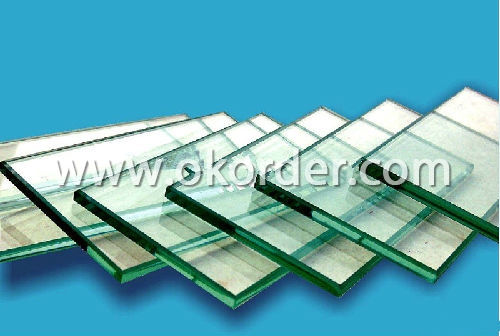

Specifications of Clear Heat Reflective Coated Glass:

Thickness: 3mm;4mm;5mm;6mm;8mm;10mm;12mm;15mm;19mm

Size:

2440*3660mm

2400*3300mm

2100*3300

customized size

Applications of Clear Heat Reflective Coated Glass:

Heat-Reflective Coating Glass is mainly used for curtain walls.

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Spray glaze workshop generally volatile material is relatively small, so, as long as a good protection, do not spray out of the glaze and lungs can be. Ceramic factory occupational disease is mainly pneumoconiosis, but now most of the ceramic dust prevention in this area is much better than before.

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- Mosaic is mainly divided into glass mosaic (raw materials for glass) and ceramic mosaic two. Mainly used for decorative wall.

- Q: Is the production of glass materials as thin as possible? Why?

- Glass production is very strict to the granularity of various raw materials, and there is a usable range. Generally, refractory materials are finer, such as sand and feldspar. Some of them are coarse, such as dolomite and limestone. However, the most taboo is "superfine powder""!

- Q: Raw material, processing method and ratio of glass fiber reinforced plastic

- The proportion of glass fiber reinforced plastic material is the business secret of each glass fiber reinforced plastic processing enterprise, and will not be easily informed.

- Q: What are the cutting and cutting of acrylic and aluminum-plastic plates?

- Acrylic comes from English Acrylic, generic name for Acrylic acrylic and methacrylic acids chemicals. Including monomers, plates, aggregates, resin and composite material, acrylic acid methyl ester by methyl monomer (MMA) polymerization, namely polymethylmethacrylate (PMMA) organic glass plate, "organic glass" from the name "Oroglas" (a PMMA), from the "Organic Glass" (organic glass).

- Q: The main raw material for the impact of float glass cost?

- About the 70% main components of float glass is silica, the main raw material is corresponding to the sandstone or silica sand (sand), the raw material price level will seriously affect the glass manufacturing cost.

- Q: What kind of material is made of automobile glass?

- Compared with ordinary glass, automotive glass is glass, broken is very small granular, may reduce damage. Automobile front windshield PVB interlayer, strong ability uprising.

- Q: What is the raw material of glass glue?

- Mainly divided into two categories: neutral acid silicone rubber polyurethane adhesive can be indoor and outdoor weathering 107 RTV silicone rubber and calcium carbonate, silica, additives, mixing, vacuum glass glue chemical formula: 107RTV+SiO2+CaCO3= glass glue according to the technical requirements of the chemical equipment selection will differ.

- Q: What raw material is the front bumper of the car made of?

- The front bumper of the car is made of toughened glass.

- Q: Mobile phone film new flexible toughened glass membrane, really is the glass?

- Glass membrane materials: ab. Because the plastic protective film glass film unlike can electrostatic adsorption on the mobile phone screen, with a thin layer of flexible double-sided adhesive tape in the glass film layer, this thin layer of flexible double-sided adhesive is called ab.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 1994 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | Asia; Oceania; Mid East; Eastern Europe; North America; South America; Africa; |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 61% - 80% |

| No.of Employees in Trade Department | Above 1000 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Clear Heat Reflective Coated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m2 m²

- Supply Capability:

- 10000 m2 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords