Colored Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated Glass is made of high quality float glass, coated glass of various colors, Low-E glass, tempered glass, thermo-strengthening glass and bent/tempered glass. It is a product integrated with two or more glass sheets and one or more layers of organic polymers like PVB, EVA, SGP, etc. It is processed by the tablet machine under high pressure and high temperature, making it unite into one lastingly.

Features of Colored Laminated Glass:

1. Safety glass

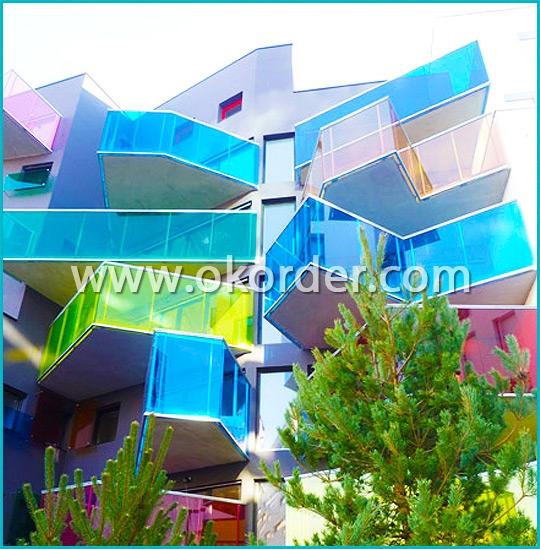

2. Fine light control and heat insulation when using coated glass

3. Sound insulation and noise reduction

4. Good structural feature

5. In order to guarantee the quality of laminated glass, the PVB films are imported from Dupont of the USA or Sekisui of Japan.

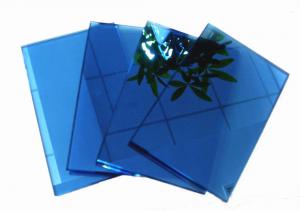

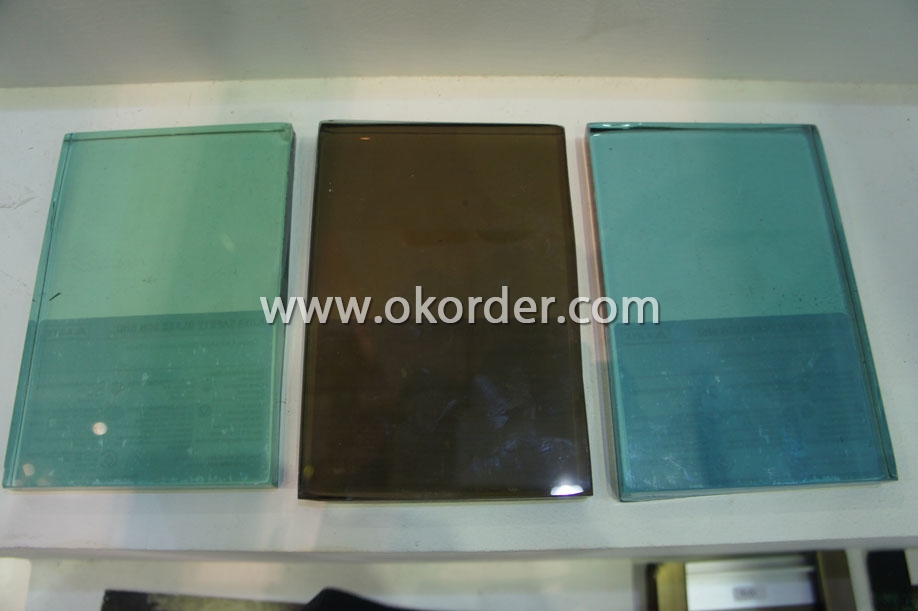

6. The colors of the films include clear, milk, blue, dark grey, light green, bronze, etc.

Specifications of Colored Laminated Glass:

Thickness of Glass: 3mm+3mm; 4mm+4mm; 5mm+5mm; 6mm+6mm; 8mm+8mm; 10mm+10mm; 12mm+10mm

Thickness of PVB film: 0.38-3.04mm

Size:

Min Size: 300*300mm

Max Size: 3000*8000mm

customized size

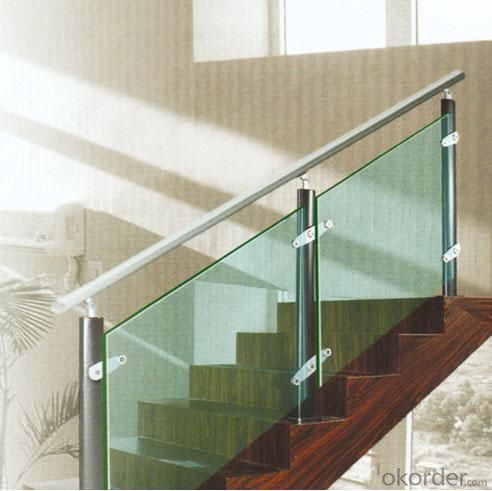

Applications of Colored Laminated Glass:

Laminated Glass is applied in curtain walls, hotels, banks, airports, sunshades, lighting roofs, windows and gates, sprung roofs, indoor glass partitions, glass furniture, show windows, bars, jewelry shops, elevators and so on.

- Q: How is the glass made?

- Glass cup making process:1: silk;2: blow the ball;3: skin opening;4: inner opening and back cover;5: interface;6: back cover;7: affixed trademarks;8: annealing.Glass (glass) is the raw material is a glass of glass, usually raw material is high borosilicate glass, after more than 600 degrees of high temperature firing, it is a new type of environmentally friendly tea cup, more and more people's favor.

- Q: How can glass frosting be formulated? What raw materials do you use?

- Preparation of water-based environment-friendly frosting liquid, according to the A Group 8, B group of 2, the proportion with 5 copies of the preparation of tap water (25kg water frosting powder add 12.5Kg, preparation of tap water) according to the proportion of A group and B group into a plastic bucket, then according to the proportion of entering tap water (if prepared with 80 degrees above water could shorten the curing time more than half) with plastic (or bamboo sticks) stir until evenly, liquid will be prepared to cover seal, so that in the outdoor temperature under natural curing for 24 hours. The newly formulated frosting is thicker and the temperature drops. After ripening, the viscosity and temperature of the liquid can be restored to normal. When the preparation amount is large or the weather is cold, the aging time should be prolonged appropriately.

- Q: Why is toughened glass broken?

- There are a variety of predisposing factors. Tempered glass explodeFor example, A. before the installation of glass is accidentally damaged, like chipping, knocked the feet, because the glass is tempered around the weak area, its strength even weaker than the non tempered glass, but this part of the damage are not likely to cause the glass immediately burst, but changed the internal stress of glass. When the upper wall is used, the internal stress changes gradually, which breaks the glass.B. such as differences in temperature after installation. As you say, temperature, weather, and so on, will make the internal pressure of the glass partial uneven, thus causing burst.Is there a correct size for the C. installation?. If the installation is too tight, the specifications are not appropriate, it will cause stress changes inside the glass, causing a burst.D. the rest is external force, including impact, extrusion and so on. It's not just human impact, or other things, or even wind in nature. If the glass does not fall on the ground, there will be the point of impact (if it is obvious, there will be explosive, Hu Dieban) these can be invoked, but if in the proceedings can only be said to be a possibility, because you have no evidence to prove that. In the domestic situation, the glass manufacturers generally compensate for the glass trouble.

- Q: What is resin glass fiber reinforced plastic?

- Resin is the main raw material of glass fiber reinforced plastics. The so-called FRP is a kind of composite material made of glass fiber reinforced fiber and its products (glass cloth and band) as reinforcing material and chorus resin as matrix

- Q: There are several appearances of the quality defects of ordinary flat glass

- There in the flat glass some prominent particles, called big lump or small stones, called sand. It mainly affects the optical properties of glass and makes it difficult to cut glass.

- Q: Why a broken glass film

- A ton of glass raw materials, at least 3-4 of nickel sulfide crystals, the number of tons of glass made of pieces of a square size glass, which will have 3-4 to explode, which is self depicting the image of.

- Q: What are the raw materials for making glass?

- Sandstone fused glass has a bright luster, and has a good transparency, acid resistance and mechanical strength.

- Q: What does GF30 represent in plastic PP GF30?

- Polypropylene reinforced by glass fiber, mechanical properties, creep resistance and dimensional stability can be improved,.PP-GF30T has a good low-temperature resistance and high impact strength, PP-GF30 heat resistance

- Q: What kind of glass material is used in the aquarium?

- Ordinary glassEmerald green, fragile, transparency is not high, rain, exposure, aging, deformation, and do not amount to the production of fish tanks.

- Q: Which brand of thermos cup is safe, double glass is not really glass, there is no other add, affect health?

- Insulation cup is generally made of ceramic or stainless steel containers with vacuum layer made of water, the top cover, seal, vacuum insulation layer can make the liquid inside the slow cooling, in order to achieve the purpose of preservation.

1. Manufacturer Overview

| Location | Jiangsu, China |

| Year Established | 2008 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | Northern Europe, Africa |

| Company Certifications | Certificate for China Compulsory Product Certification |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 9 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered; Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

Colored Laminated Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords