Colored Aluminum Sheets for Campers - Versatile Aluminum Sheet/Coil and Foil Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

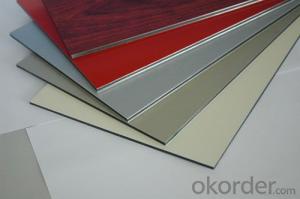

Aluminum sheet coil and foil for versatile application

1).Alloy:1050 1060 1070 1100 3003 3004 3005 5052 5083 5754 8011

2).Temper:O H14 H16 H18 H24 H26 H32 H111

3).Thickness:0.2-8mm

4).Width:50-1900mm

5).Application:Construction, decoration, pipe, packaging, automobile, air conditioning, pot containers, refrigeration, electrical and electronic products, etc.

At present, we can supply 1xxx 3xxx 5xxx 8xxx series aluminum alloy sheet/ plate/ coil/ foil in various specification. With good quality and competitive price, we will furnish you the best product and serive.

Aluminum sheet

| Allloy | Specifications(mm) | Temper | Standard | Application | |

| Thickness | Width | ||||

1070,1060,1145, 1050,1100,1235 | 0.2-6.0 | 900-1900 | O,H12,H22,H14, H24,H16,H26,H18 | GB/T3190-1996 GB/T3880-1997 | Construction,decoration, pipe,packaging,automobile, air conditioning,pot containers,refrigeration, electrical and electrical products,etc. |

| 3A21,3003,3004 | 0.2-6.0 | 900-1900 | O,H14,H24,H18 | GB/T3190-1996 GB/T3880-1997 GB/T3194-1997 | |

| 5052,5A02,5005 | 0.2-6.0 | 900-1900 | O,H12,H22,H32, H14,H24,H34,H16, H26,H36,H18,H38 | GB/T3190-1996 GB/T3880-1997 | |

| 8011 | 0.2-6.0 | 900-1900 | O,H14,H24,H18 | GB/T3190-1996 GB/T3880-1997 | |

Aluminum coils

| Allloy | Specifications(mm) | Temper | Standard | Application | |

| Thickness | Width | ||||

1070,1060,1145, 1050,1100,1235 | 0.2-12 | 25-1900 | O,H12,H22,H14, H24,H16,H26,H18 | GB/T3190-1996 GB/T3880-1997 | Construction,decoration, pipe,packaging,automobile, air conditioning,pot containers,refrigeration, electrical and electrical products,etc. |

| 3A21,3003,3004 | 0.2-12 | 25-1900 | O,H14,H24,H16, H26,H18 | GB/T3190-1996 GB/T3880-1997 GB/T3194-1997 | |

5052,5005, 5754,5083 | 0.2-12 | 25-1900 | O,H12,H22,H32,H14, H24,H34,H16,H26, H36,H18,H38 | GB/T3190-1996 GB/T3880-1997 | |

| 8011 | 0.2-12 | 25-1900 | O,H14,H24,H16, H26,H18 | GB/T3190-1996 GB/T3880-1997 | |

Aluminum foil

| Alloy | Specifications(mm) | Temper | Standard | Application | |

| Thickness | Width | ||||

1100,1200,1050 1060,1070 | 0.0065-0.200 | 15-1200 | O,H22,H14,H24 H16,H26,H18, H19 | GB/T3190-1996 GB/T3198-2003 YS/T430-2000 YS/T95.1-2001 | Air-conditioning,cable, cigarettes,food,medicine, decoration,capacitor, beer,drinks,etc |

| 3003,3004,3005 | 0.012-0.200 | 15-1200 | O,H14,H24,H16 H26,H18 | GB/T3190-1996 GB/T3198-2003 | |

5052 5005 5754 5083 | 0.012-0.200 | 15-1200 | O,H14,H24,H16 H26,H18 | GB/T3190-1996 GB/T3198-2003 | |

| 8011 | 0.0065-0.200 | 15-1200 | O,H22,H14,H24 H16,H26,H18 H19 | GB/T3190-1996 GB/T3198-2003 | |

- Q: I have been doing this science prac at school and I have received some strange results. I measured the density of this metal, which leads me to believe it is Aluminium. Also, its silvery appearance supports this. When I have attempted to react it with Hydrochloric Acid, Sulfuric Acid and the nitrates/chlorides of a few metals, I have received some odd results.Despite having a high reactivity, the only substance it has reacted with so far out of all of the above is Tin Chloride. Am I doing something wrong? Is it possible that it isn't aluminium and rather a similar metal such as zinc? Thanks in advance :)

- Aluminum is very reactive so what happens is that it has a coat aluminum oxide as soon as it comes in contact with oxygen the outer layer forms aluminum oxide Al2O3. That is why Aluminum does not rust. The Al203 coat protects it.

- Q: i went on the apple education site cuz i was gonna order an aluminum today, and it isnt there anymore!!!! i was on it like 2 hours ago and it was...wtf!!! anyone know whuts up?

- No... all of their computers are made of aluminum (except for the old white macbook) so it'd be kind of hard for them to stop selling aluminum computers. Which one were you looking at? the iMac, mac mini, macbook pro? If you were looking for the regular macbook you probably only saw the plastic white one because as of today, apple decided that the 13inch aluminum unibodies were going to be added to the pro line. They saw a slight spec bump and now come with a new and improved battery and I believe faster processors, but all in all, still the same macbook, just with a new name. Check the macbook pro section.

- Q: Are 101 aluminum sheets suitable for outdoor signage?

- Yes, 101 aluminum sheets are suitable for outdoor signage. They are corrosion-resistant, durable, and can withstand various weather conditions, making them a suitable choice for outdoor applications.

- Q: Can aluminum sheets be polished for a mirror-like finish?

- Yes, aluminum sheets can be polished to achieve a mirror-like finish. Aluminum is a relatively soft metal and can be easily polished to a high shine. The process typically involves sanding the surface with progressively finer grits of sandpaper, followed by buffing with polishing compounds and a soft cloth or a polishing wheel. The goal is to remove any scratches or imperfections on the surface and create a smooth, reflective finish. With the right techniques and tools, aluminum sheets can be polished to a mirror-like shine, making them suitable for various applications such as decorative purposes, automotive parts, or reflective surfaces in optical devices.

- Q: Are aluminum sheets suitable for electronics applications?

- Yes, aluminum sheets are suitable for electronics applications. Aluminum is a versatile and lightweight metal that offers excellent conductivity, making it an ideal choice for various electronic components and applications. Aluminum sheets are commonly used in the electronics industry for heat sinks, enclosures, PCB (printed circuit board) substrates, and connectors. Heat sinks made from aluminum sheets help dissipate heat generated by electronic devices, ensuring their optimal performance and preventing overheating. Additionally, aluminum sheets are often used as enclosures for electronic devices due to their durability, corrosion resistance, and ability to shield against electromagnetic interference. They provide a protective casing that ensures the safety and functionality of delicate electronic components. Aluminum sheets are also used as PCB substrates due to their excellent thermal conductivity. They help in dissipating heat generated by the electronic components on the PCB, preventing damage and ensuring the proper functioning of the circuit. Furthermore, aluminum is a cost-effective material compared to other metals commonly used in electronics, such as copper. This makes it a popular choice for various electronic applications, especially for mass production. In conclusion, aluminum sheets are highly suitable for electronics applications due to their conductivity, durability, corrosion resistance, and ability to dissipate heat. They offer numerous benefits and are widely used in the electronics industry for heat sinks, enclosures, PCB substrates, and connectors.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

- Q: Are 101 aluminum sheets suitable for medical equipment?

- No, 101 aluminum sheets are not suitable for medical equipment. Medical equipment requires materials that are highly durable, corrosion-resistant, and have excellent biocompatibility. While 101 aluminum is a strong and versatile alloy, it does not possess the necessary characteristics for medical equipment. Instead, medical equipment manufacturers typically use specialized alloys such as stainless steel or titanium, which offer superior strength, resistance to corrosion, and compatibility with the human body. It is essential to prioritize the safety and effectiveness of medical equipment by selecting appropriate materials that meet the specific requirements of the healthcare industry.

- Q: What are the cost considerations when purchasing aluminum sheets?

- There are several cost considerations when purchasing aluminum sheets. Firstly, the size and thickness of the sheets will affect the price, with larger and thicker sheets generally being more expensive. Additionally, the grade and quality of the aluminum will impact the cost, as higher-grade alloys tend to be pricier. The quantity of sheets being purchased also plays a role, as bulk orders often come with discounts. Finally, transportation and delivery costs should be taken into account, especially if the supplier is located far from the buyer.

- Q: 5052 aluminum plate and LY12 aluminum plate is the same?

- The 5052 series is aluminum magnesium alloy, the magnesium alloy belongs to the lower density alloy, the 5052 alloy aluminum plate density is 2.68

- Q: Are aluminum sheets suitable for high-temperature applications?

- High-temperature applications are generally not suitable for aluminum sheets. Despite its relatively high melting point of 660.3°C (1220.5°F), the strength and mechanical properties of aluminum decrease significantly as the temperature rises. Aluminum tends to soften, deform, and lose its structural integrity at elevated temperatures. Moreover, its relatively low thermal conductivity hinders efficient heat conduction away from the source, resulting in potential overheating problems. Hence, stainless steel or refractory metals like titanium or tungsten are commonly preferred for high-temperature applications due to their superior performance and thermal conductivity.

Send your message to us

Colored Aluminum Sheets for Campers - Versatile Aluminum Sheet/Coil and Foil Applications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords