Color Steel Color Rolled/ Printed Color Galvanized Steel Coilfor Sandwich wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Military Printed Color Galvanized Steel Coil

1. Techinical standard: EN10169

2. Grade: TDX51D, TSGCC

3. Color: Ral standard or according to customers' requirment

4. Thickness: 0.14-0.8mm (the most advantage thickness)

5. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250)

6. Base metal: Galvanized / galvalume steel / cold rolled

7. Finish Painting: 15-20miu PE on top

Back painting: 5-8miu EP on back

8. Type of PPGI: PPGI with military pattern

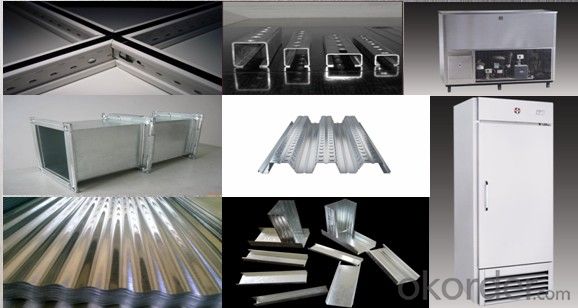

Product category and properties: The products can be divided into the following sorts in the light of their specific manufacturing and processing methods:

1. Hot-dip galvanized steel coil. Its the most common galvanized steel product at present.

2. Hot-dip galvalume steel coil. Al-Zn galvanized steel sheet. General use, construction industry, household appliance industry, automobile industry and industrial instruments.

3. Color coating steel coil. Any color according to the requests of customers. General use, for drawing, structure, construction industry (outdoor), factory building, agricultural warehouse, prefabricated ports of residence, title roof and furniture appliance.

4. Guardrail. Highway guardrail/fence can be used for both sides of highway and road. Available in any different sizes. Hot-dipped galvanized or galvalume steel sheet. Spraying plastics in your exact specifications.

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| commodity | Color-coated Galvanized Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness)) |

| Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

Q&A What is the validity of your quotation?

ANSWER: Normally 2 days

- Q: What is the role of steel coils in HVAC systems?

- Steel coils play a crucial role in HVAC (heating, ventilation, and air conditioning) systems as they are responsible for facilitating the transfer of heat between the air and the refrigerant. In HVAC systems, steel coils are typically used in two main components: the condenser coil and the evaporator coil. The condenser coil is located in the outdoor unit of an HVAC system and its primary function is to release the heat from the refrigerant into the surrounding air. This coil is made up of multiple steel tubes that are bent into a serpentine shape and are attached to aluminum fins. As the hot refrigerant flows through these tubes, the steel coils ensure maximum surface area contact with the surrounding air, allowing for efficient heat transfer. Through this process, the heat is dissipated into the outdoor environment, resulting in the cooling of the refrigerant. On the other hand, the evaporator coil is situated in the indoor unit of the HVAC system and its role is to absorb heat from the air inside the building. Similar to the condenser coil, the evaporator coil consists of steel tubes that are connected to aluminum fins. The refrigerant, in a cold state, flows through these tubes, and as warm air from the building passes over the coils, the heat is transferred from the air to the refrigerant. This heat absorption process cools down the air, which is then circulated back into the building, providing the desired cooling effect. Overall, steel coils in HVAC systems are essential for heat transfer between the air and the refrigerant. Their design and placement allow for efficient cooling or heating of the air, depending on the system's mode of operation. Without steel coils, HVAC systems would not be able to effectively regulate the temperature and provide the desired comfort levels in residential, commercial, and industrial buildings.

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: My boyfriend is a loyal follower of this guy called Dr. Steel.

- Dr. Steel is an extremely complex phenomenon, a bit of a metaphorical nesting doll. On the surface, Dr. Steel can appear to some as simply a method actor musician with an over-the-top gimmick. Just underneath that facade lies an enigma; he makes some people wonder if he's really serious, just trying to entertain, or completely barking mad. But underneath the second facade, Dr. Steel is really acclaimed comic-book writer and chaos magickian, Grant Morrison. Make no mistake, he really thinks he is Dr. Steel. He has taken method acting and ceremonial magick to the highest levels, and fully intends to take over (or make over) the world. What's more, in the three short years since handing over his comic-book authorship to a ghost writer, he has amassed tens of thousands of followers worldwide. I've done several polls among Dr. Steel fans, and the results show that for every one person who has officially signed up, there are ten more loyal followers who have not.

- Q: What are the common tests performed on steel coils?

- The common tests performed on steel coils include dimensional inspection, visual inspection, chemical composition analysis, mechanical testing (such as tensile and hardness tests), coating thickness measurement, and surface quality assessment.

- Q: I don't know why but I'm having a VERY difficult time finding the melting point of 1008 steel.

- 1. okorder 2. Input (melting point 1008 steel) as the search string 3. Check the links; the third one showed the answer in an MSDS

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks by being shaped and cut into the desired hook shape. The coils are uncoiled and fed into a machine where they undergo various processes such as bending, shaping, and welding to form the hooks. The strength and durability of the steel coils contribute to the quality and reliability of the final steel hooks.

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- This Site Might Help You. RE: Whats better chrome vanadium steel or carbon stainless steel? I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Q: How are steel coils used in the production of metal signs?

- Steel coils are used in the production of metal signs as they are processed and shaped into flat sheets that serve as the base material for the signs. These coils are unrolled and flattened, then cut and formed into the desired shape before being painted or coated for aesthetics and protection.

- Q: How are steel coils used in the production of doors and windows?

- Steel coils are vital components in the production of doors and windows due to their strength and versatility. These coils are typically made from high-quality steel and are used in various stages of the manufacturing process. Firstly, steel coils are used to create the frame of the doors and windows. The coils are unrolled and cut into specific lengths, depending on the desired dimensions of the frame. The steel is then bent and shaped into the required frame design, ensuring that it is strong and durable. Next, the coils are used to produce the panels or glass holders for the doors and windows. The steel is cut and formed into the desired shape, and then it is either welded or attached to the frame. This ensures that the doors and windows have a sturdy structure and can handle the weight and pressure of the glass or panels. Additionally, steel coils are also used to create the hinges and other hardware components of the doors and windows. The coils are cut and shaped into the necessary parts, ensuring that they are strong enough to support the movement and functionality of the doors and windows. Furthermore, steel coils can be used for decorative purposes. They can be embossed or coated with different finishes to enhance the appearance of the doors and windows. This allows for a wide range of design options, enabling manufacturers to create doors and windows that suit various architectural styles and preferences. In summary, steel coils play a significant role in the production of doors and windows. They are used to create the frame, panels, hinges, and other hardware components, ensuring strength, durability, and functionality. Additionally, they can be used for decorative purposes, allowing for customization and aesthetic appeal.

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets as they serve as the primary raw material. The coils are processed through various manufacturing techniques such as cutting, bending, and welding to shape and form the brackets. The high strength and durability of steel coils ensure that the brackets maintain their structural integrity and can withstand heavy loads or harsh conditions.

Send your message to us

Color Steel Color Rolled/ Printed Color Galvanized Steel Coilfor Sandwich wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 18000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords