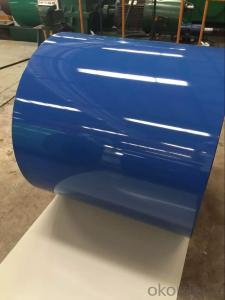

color steel coil/prepainted galvanized steel coil/PPGI for roofing and construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | waterproof paper+steel sheet+outer/inner protective circles+side protective guard+wood pallet |

| Delivery Detail: | within 30 days after received deposit or L/C at sight |

Specifications

1.color steel coil

2.thickness:0.12-2.0mm

3.width:900-1250mm

4.certificate:ISO 9001:2008

5.manufacturer

Company introduction of color steel coil :

Shandong Luli Steel Co. Ltd, founded in 1993, is a holding company of Luli Group, located in Weifang city, Shandong

province,China. It is a joint steel manufacturer with 2 PPGI production line,1 GI and Aluzinc production line,

15 different kinds of corrugated steel roofing sheet machines and 5 different kinds of load bearing plate

machines.Products have passed ISO9001 international quality system authentication.Leading products include:

(1)0.12mm-2.0mm*900mm-1250mm*C prepainted galvanized steel coil

(2)0.15mm-2.0mm*900mm-1250mm*C hot dipped galvanized steel coil and aluzinc steel coil

(3)0.30mm-1.0mm*750mm-1075mm*C corrugated steel roofing sheets

(4)0.80mm-1.2mm*600mm-720mm*C load-bearing plates

Products have exported to Korea, Japan and Southeast Asia with good reputation.Luli Steel Co., Ltd warmly welcomes

all the customers to come to visit factory.If you are interested in our products,pls feel free to contact me.You could

also add me on SKYPE or WHATSAPP to contact in time.Detail contact information as follow:

Contact person | |

SKYPE | |

Trademanager | |

Moble | |

Tel. | |

Fax. | |

Website |

Production introduction of color steel coil :

Commodity | PPGI/PPGL |

Standard | JIS G3302, JIS G3313, ASTM A653, GB/T2518-88, GB11253-89,, BS, ect. |

Grade | SGCC,CGCC,SGCD,SPCC,DX51D,DX52D,DX53D |

Thickness | 0.12mm-2mm |

Width | 900-1250mm |

Coil ID | 508mm/610mm |

Coil Weight | 3-6tons |

Zinc Coating | Z20-Z270g/m² |

Color | sea blue,white grey , bright red or according to RAL color system |

Thickness of coating | Top coating:12-25 microns,back coating:5-8microns |

Technique | Cold rolled galvanized steel coil,galvalume steel coil |

Surface Production | PE,PVDF,SMP,HDP,ect. |

Application | Roofing, Corrugated Roofing Making,Outside of the buildings,Structure,Wall, Deep Drawn |

Delivery time | About 30 working days after received client deposit or irrevocable L/C at sight |

Shipment | Container or bulk |

Payment Term | L/C,T/T |

Production line instruction of color steel coil :

loading coil-uncoil-stitching machine-entry looper-first time alkali cleaning-second time alkali

cleaning-first time hot water washing-second time hot water washing-epoxy primary coating-primary coating drying-first time water quenching-polyester top coating-high tempreture top coating dry-second time water quenching-outlet looper-cut down-unloading coil-weighing-packing and warehousing

- Q: How are steel coils affected by global trade policies?

- Steel coils are significantly affected by global trade policies as they are subject to various tariffs, quotas, and trade restrictions imposed by different countries. These policies can impact the cost, availability, and competitiveness of steel coils in the international market. Changes in trade policies can lead to fluctuations in demand and supply, impacting the prices and trade volumes of steel coils.

- Q: Steel roofing info. Pros and cons on steel roofing?

- Steel roofing Pro...life of product is much longer then Asphalt shingles....Looks great...multi colors.......Just love the stuff... Cons....More costly then singles at first but since it last longer it is really a better buy.......

- Q: What are the dimensions of steel coils used in the transportation equipment industry?

- The dimensions of steel coils used in the transportation equipment industry can vary depending on the specific requirements and applications. However, there are some common dimensions that are widely used. The width of steel coils used in the transportation equipment industry typically ranges from 600mm to 2000mm (24 to 78 inches). This width is chosen to ensure compatibility with the machinery and equipment used for transportation, such as trucks, trailers, and railcars. The thickness of steel coils can vary greatly depending on the specific application and the desired strength of the material. However, common thickness ranges for transportation equipment industry steel coils are typically between 0.5mm and 6mm (0.02 to 0.24 inches). The inner diameter of steel coils used in the transportation equipment industry is typically standardized at either 508mm (20 inches) or 610mm (24 inches). This standardization allows for easy handling and compatibility with the machinery used in the industry. The outer diameter of steel coils can vary depending on the width and thickness of the coil. However, common outer diameter ranges for transportation equipment industry steel coils are typically between 1000mm and 2200mm (39 to 87 inches). It is important to note that these dimensions are not fixed and can be customized based on specific requirements and applications within the transportation equipment industry.

- Q: What are the different methods of coil leveling?

- The different methods of coil leveling include roller leveling, stretcher leveling, and temper leveling.

- Q: What are the different methods of steel coil surface cleaning?

- There are several different methods of steel coil surface cleaning, including mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials or brushes to remove dirt, rust, and other contaminants from the surface of the steel coil. Chemical cleaning involves using chemicals or solvents to dissolve or remove contaminants from the surface. High-pressure water cleaning uses water jets at high pressures to remove dirt and debris from the surface. Each method has its own advantages and is chosen based on the specific requirements and condition of the steel coil.

- Q: How are steel coils used in the production of doors and windows?

- Steel coils are used in the production of doors and windows as they provide the raw material for manufacturing the frames and components. The coils are processed and shaped into the desired profiles, which are then used to construct the frames, sashes, and other structural elements of doors and windows. This ensures strength, durability, and stability in the final products.

- Q: How are steel coils used in the manufacturing of seat structures?

- Steel coils are used in the manufacturing of seat structures by being shaped and molded to create the framework and support system of the seats. The coils provide strength and stability to the structure, ensuring durability and comfort for the users.

- Q: How are steel coils inspected for hardness using hardness testers?

- To assess the strength and durability of steel coils, hardness testers are employed to examine their hardness. Hardness testers are specialized devices used to gauge a material's resistance to indentation or penetration. For steel coils, Rockwell or Brinell testers are commonly utilized. Both methods entail exerting a precise force onto the surface of the coil and measuring the depth of indentation or size of the impression made. In the case of Rockwell testing, a steel ball or diamond cone is pressed onto the coil's surface with a predetermined force. The depth of penetration is then measured and compared to a standardized scale in order to determine the hardness value. Different scales are employed based on the size and type of indenter in use. On the other hand, Brinell testing involves using a spherical indenter made of tungsten carbide or hardened steel. This indenter is pressed onto the coil's surface with a known force, and the resulting indentation is measured and compared to a standardized table to determine the hardness value. Both methods provide a quantitative measure of the steel coil's hardness, which serves as an indicator of its ability to resist deformation, wear, and cracking. The hardness test results are subsequently utilized to ensure that the steel meets specific quality standards or customer requirements. It is important to note that the inspection process may involve sampling, where representative sections of the steel coil are tested, or it may involve testing the entire coil, depending on the specific inspection requirements. Additionally, accurate and reliable results necessitate proper calibration and maintenance of the hardness testers.

- Q: Ive been playing with my ping i3 graphite irons for 6 years now and some days i can hit it and some days i cant. Then i tried out my friends irons the other day and he had steel and i was hitting the ball anywhere i wanted it to go..Is that a fluke or is steel irons just better than shaft? I was thinking about trading my graphites for steel, is that a good idea??

- Graphite is a lot lighter and will allow you to generate more swing speed and probably greater distance. I hit my graphite clubs about one club longer than my steel shafts. But, my steel shafts are far more accurate. I find I hit a lot more greens in regulation using my steel shafted irons than I do with my graphites. Since accuracy is far more important than distance for most people, I choose the steel shafted irons most of the time. You will NEVER see a professional or a low handicapper using graphite irons for this reason.

- Q: How are steel coils used in the manufacturing of wind turbines?

- Steel coils are used in the manufacturing of wind turbines to create the main structural components, such as the tower and the nacelle. These coils are shaped and welded to form the strong and durable framework that supports the turbine's blades and houses the generator. Additionally, steel coils are also used to fabricate other essential parts, such as the hub and the base, ensuring the stability and efficiency of the wind turbine.

Send your message to us

color steel coil/prepainted galvanized steel coil/PPGI for roofing and construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords