Color Coated Steel Sheet (ASTM A755) for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:Ral 3012

Standard:AISI

Steel Grade:ASTM A755

Surface Treatment:Coated

Technique:Cold rolled, Hot dipped, Pre-painted

Export Markets:Global

Additional Info.

Packing:Standard Sea Worthy Package

Standard:ASTM A755

Origin:China

HS Code:72107000

Production Capacity: 18, 000~25, 000 Tons Per Month.

Product Description

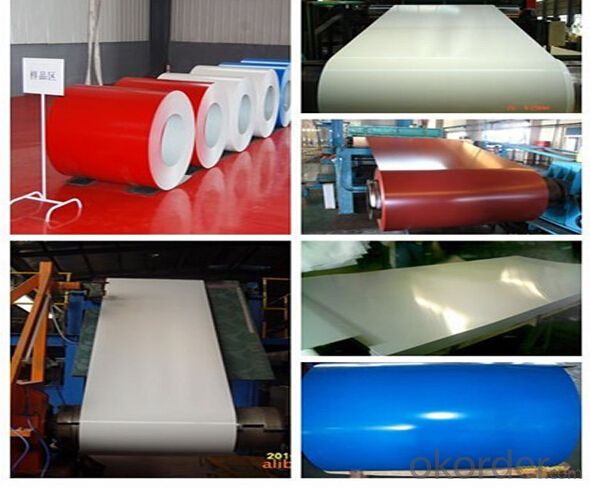

NAME: Prepainted Steel Coil\Colour Coated Coil\Coil coated steel\PPGI

SIZE:

Thickness: 0.18-1.50mm

Width: 10mm-1500mm(STD914mm,1000mm, 1200mm, 1219mm, 1250mm, 1500mm)

Thickness tolerance: +/-0.05 mm

Width tolerance: -2.0/5.0mm

ZINC, PAINT & COLOR:

Zinc coating: 60-275G/M2

Paint thickness: Top 15-25um + Back 5-10um

Paint: polyester, silicone polyester, acrylic, fluoropolymer, plastisol, or polyurethane

Color: As the RAL color standard or customer's sample

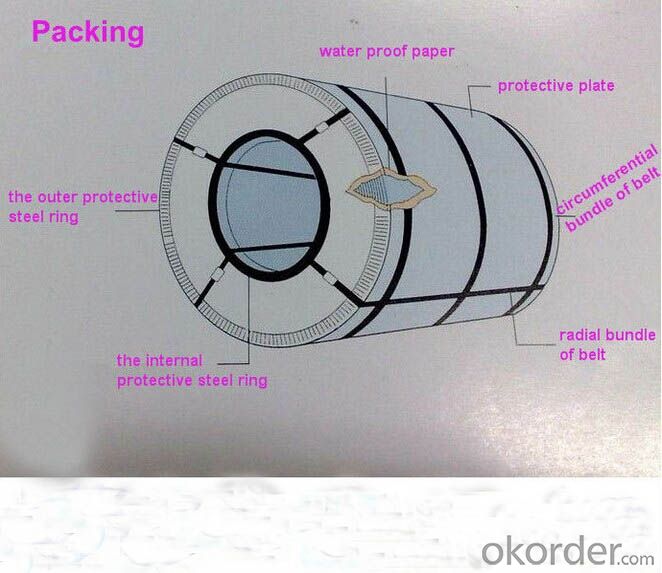

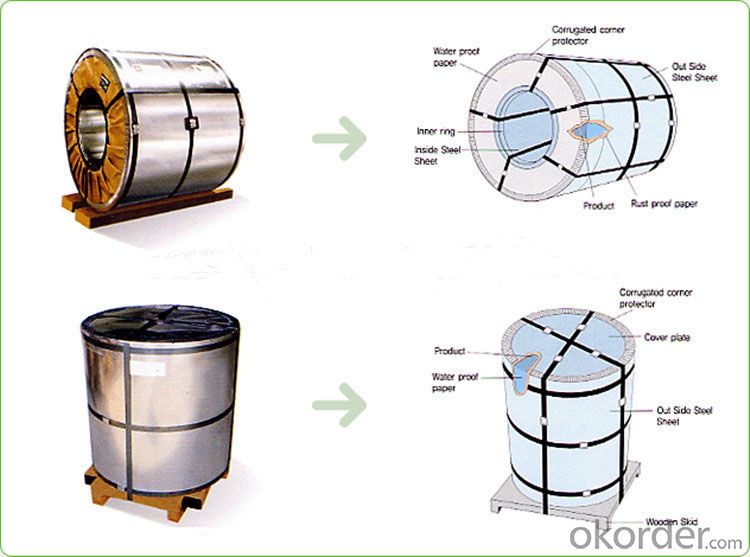

PACKING:

Coil weight: 3-10tons

ID: 508mm\610mm

Standard sea worthy package

STANDARD:

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: SGCC, CGCC, DC51D+Z, Q195,etc

Quality: CQ DQ

Lifespan: 10-15 years

APPLICATION:

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door\Door of garage\Roller shutter door\Booth\Persian blinds\Cabana\Refrigerated wagon and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\Sliding door\Folding screen\Ceiling\ Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C,

Acceptable price term?

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are the common methods of protecting steel coils from corrosion?

- Common methods of protecting steel coils from corrosion include applying a protective coating, such as zinc or paint, using corrosion inhibitors, storing coils in a controlled environment with low humidity, and implementing proper handling and packaging techniques to prevent moisture exposure.

- Q: How many pounds can steel lift?

- much too vague. Need the shape and thickness of the steel, where it is supported, and where the load is placed.

- Q: I am wondering if i can use my western guitar as a kind of steel-guitar, read something about it on Wikipedia.

- If you decide to get a true pedal steel, plan on spending some big money. Look on eBay for a Carter Starter. It will be the best guitar to start on...and not outgrow too fast.

- Q: How are steel coils used in the production of steel knobs?

- Steel coils are used in the production of steel knobs by being fed into a stamping machine, where they are cut into the desired shape and size. The coils provide a continuous supply of steel material, ensuring efficiency and consistency in knob production.

- Q: I remember my dad saying something about steel toed boots but I forgot =#92; I went and checked out all the stores and got a pair with good ankle support but they also have steel toes. Would this interfere with the shifter or anything? I figure if anything my dirt bike shoes have the steel toes too. Any opinion?

- My work boots are steel caps i ride to work and home in them. I also wear them when I'm too lazy to change into my proper boots.I don't see any dramas with you wearing them they do come in handy for dogs that try to latch onto you. Ride safe.

- Q: How are steel coils used in the manufacturing of machinery?

- Steel coils are used in the manufacturing of machinery as they provide a reliable and durable material for various components and structures. These coils are often shaped, cut, and formed into desired parts such as gears, shafts, frames, and supports. The high strength and versatility of steel coils allow them to withstand heavy loads and harsh conditions, ensuring the machinery's efficiency and longevity.

- Q: What are the advantages of using pre-painted steel coils?

- There are several advantages to using pre-painted steel coils. Firstly, pre-painted steel coils have a protective coating applied during the manufacturing process, which makes them resistant to corrosion and increases their lifespan. Additionally, the pre-painted coating provides a smooth and aesthetically appealing finish, eliminating the need for further painting or finishing. This saves time and money on additional coatings or treatments. Moreover, pre-painted steel coils are available in a wide range of colors and finishes, allowing for greater design flexibility and customization. Lastly, pre-painted steel coils are easy to install, lightweight, and have excellent durability, making them an ideal choice for various applications in construction, automotive, and other industries.

- Q: like the steel industry and the effects it had on industrial growth, 10 points!

- The single most important important advance in steel production was learning to accurately control carbon content. This was done through the Bessemer Process in which air was blown through molten iron to burn out impurities and excess carbon. Low carbon iron (wrought iron) could be easily worked into shapes. Medium carbon iron could be cast into useful and durable shapes. High carbon steel could be used for structural uses (beams and girders). Adding alloys such as nickel and silicon could produce very tough steels and steels resistant to rust. Adding vanadium to steel engine parts allowed Ford to produce finely machined engines in huge numbers with existing machinery.

- Q: In what ways can steel fail in use of buildings ad what can be done to prevent it?

- we fireproof steel in buildings now if thats what your talking about

- Q: Why is the steel tape tape head not fixed?

- It makes sense to be irregular;You can see the standard ruler of steel roll head is a gap, when you take the time to object quantity, the head will indent the gap, so you measure is the size of the head from the head of steel;When you hook the object, the head will pull apart and you'll take the dimension from the end of the steel head.

Send your message to us

Color Coated Steel Sheet (ASTM A755) for Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords