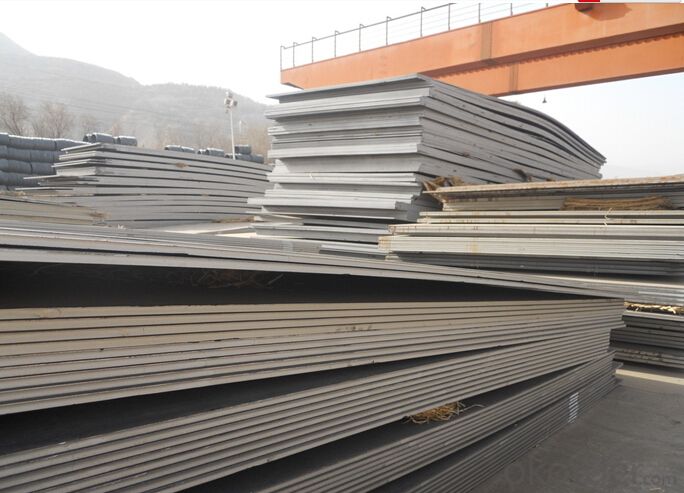

Plate Use for Boilers and Containers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plate Use for Boilers and Containers

GRADE:National standards,or in accordance with customer requirements

ADVANTAGES:Excellentseries, specifications series,low weldingcrack sensitivity, highheatinputwelding,welding performancevarieties

Aplication: Production of boilers,pressure vessels,chemical equipment, LNGstorage tanks and oiltanks

Category Arrangingrepresentative Grade Thickness

Used for Boiler and Pressure Vessel Q245R/Q345R/15Cr1MoVR/12Cr2Mo1R GB713 6-80

Pressure vesselsquenched and temperedhigh strength steel 12MnNiVR GB19189 12-40

Low-temperaturelow-alloy steelplatesfor pressure vessels 16MnDR/09MnNiDR GB3531 8-80

Lowtemperaturepressure vessel9% Nisteel 9Ni490/9Ni590A/9Ni590B GB24510 6-36

- Q: What are the safety precautions when handling steel sheets?

- When handling steel sheets, there are several safety precautions that should be followed to ensure the well-being of individuals and prevent accidents. These precautions include the following: 1. Personal Protective Equipment (PPE): It is essential to wear the appropriate PPE when handling steel sheets. This typically includes safety goggles or glasses, gloves, and steel-toed boots. PPE helps protect against potential injuries such as cuts, burns, and eye damage. 2. Proper Lifting Techniques: Steel sheets can be heavy and awkward to handle, so it is crucial to use proper lifting techniques to avoid strain or injury. Lift with your legs, not your back, and use team lifting when necessary. Avoid any sudden or jerky movements while handling the sheets. 3. Secure Storage and Transport: When storing or transporting steel sheets, ensure that they are properly secured to prevent them from shifting or falling. Use appropriate equipment such as straps or chains to secure the sheets, and make sure they are evenly distributed to maintain balance. 4. Clear Work Area: Before handling steel sheets, ensure that the work area is clear of any obstacles or debris. This will help prevent tripping or slipping hazards and provide a clear path for moving the sheets. 5. Adequate Lighting: Proper lighting is essential to ensure good visibility when handling steel sheets. Insufficient lighting can increase the risk of accidents and injuries, so make sure the work area is well-lit to avoid any potential mishaps. 6. Training and Education: It is important for individuals handling steel sheets to receive proper training and education on safe handling procedures. This includes understanding the weight and dimensions of the sheets, as well as the correct techniques for lifting and moving them. 7. Awareness of Sharp Edges: Steel sheets often have sharp edges, which can cause cuts or lacerations. Always handle the sheets with caution and be aware of any sharp edges. If necessary, use protective guards or edge protectors to minimize the risk of injury. 8. Regular Maintenance and Inspection: Regularly inspect the steel sheets for any signs of damage, such as sharp edges, rust, or structural weaknesses. Replace or repair any damaged sheets to ensure safe handling. By following these safety precautions, individuals can minimize the risk of accidents and injuries when handling steel sheets. It is important to prioritize safety and take the necessary steps to protect oneself and others in the work environment.

- Q: What is the price range of steel sheets?

- The price range of steel sheets can vary greatly depending on factors such as the type of steel, thickness, size, and market demand. It is advisable to check with suppliers or conduct research to get specific and up-to-date pricing information.

- Q: What is the typical yield strength of stainless steel sheets?

- The yield strength of stainless steel sheets can vary based on factors such as the grade and thickness of the material. On average, stainless steel sheets possess a yield strength within the range of 30,000 to 80,000 psi. It should be noted that the yield strength differs among various grades of stainless steel, such as 304, 316, or 430. Moreover, the thickness of the sheet also impacts the yield strength, with thinner sheets generally exhibiting lower yield strengths when compared to thicker sheets. Therefore, it is advisable to refer to the manufacturer or supplier's specific grade and thickness specifications to ascertain the precise yield strength of a given stainless steel sheet.

- Q: What is the maximum width of a steel sheet?

- The maximum width of a steel sheet may differ due to several factors, including the manufacturing process, equipment capabilities, and industry standards. Typically, steel sheets can be manufactured in widths ranging from a few inches to several feet. Nevertheless, in specific specialized applications, wider steel sheets beyond 100 inches or more might be accessible. To ascertain the maximum width choices available, it is advisable to consult steel manufacturers or suppliers, as it can vary based on the particular necessities and capabilities of the production facility.

- Q: What are the common applications of steel sheets?

- Steel sheets are commonly used in a wide range of applications such as automotive manufacturing, construction, infrastructure projects, appliances, shipbuilding, and the production of various metal components.

- Q: What are the different certification standards for steel sheets?

- There are several certification standards that exist for steel sheets, each with their own specific requirements and criteria. Some of the most commonly recognized certification standards for steel sheets include: 1. ASTM International: ASTM A1008/A1008M is a standard specification for cold-rolled, carbon steel sheets. This certification standard ensures that the steel sheets meet specific mechanical properties, chemical composition, and dimensional requirements. 2. American Society of Mechanical Engineers (ASME): ASME SA240 is a specification for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and general applications. This certification standard ensures the quality and safety of stainless steel sheets used in various industrial applications. 3. International Organization for Standardization (ISO): ISO 3574 is a standard specification for cold-reduced carbon steel sheet of commercial and drawing qualities. ISO 3574 certification ensures that the steel sheets have specific mechanical properties, surface finish, and dimensions. 4. European Committee for Standardization (CEN): EN 10025 is a European standard for hot-rolled structural steel products. This certification standard covers various grades and dimensions of steel sheets used in construction and engineering applications. 5. Japanese Industrial Standards (JIS): JIS G 3141 is a Japanese standard for cold-reduced carbon steel sheets and strips. This certification standard ensures that the steel sheets meet specific mechanical properties, chemical composition, and dimensional requirements. These are just a few examples of the certification standards available for steel sheets. Depending on the intended application and geographical location, there may be additional regional or industry-specific certification standards that need to be met to ensure the quality and suitability of the steel sheets.

- Q: What is the difference between a black and pickled steel sheet?

- Distinguishing a black steel sheet from a pickled steel sheet primarily lies in their surface finish and the processes they undergo. To begin with, a black steel sheet, also referred to as hot-rolled steel, is manufactured through a technique known as hot rolling. In this procedure, the steel is heated beyond its recrystallization temperature and passed through rollers to achieve the desired thickness. Consequently, the resulting sheet exhibits a dark, rough, and scaly surface, which is why it is referred to as "black steel." The dark appearance is a consequence of the oxidation that transpires during the hot rolling process. On the contrary, a pickled steel sheet is produced by means of pickling. Following the hot rolling stage, the black steel sheet undergoes a treatment where it is immersed in an acidic solution, typically hydrochloric acid or sulfuric acid. This pickling process eradicates the oxide scale from the surface of the black steel sheet, resulting in a smooth and clean surface. Additionally, the pickling process aids in enhancing the steel's resistance to corrosion. The selection between a black steel sheet and a pickled steel sheet is contingent upon the intended application. Black steel sheets are often favored for structural components, such as beams and columns, where the surface appearance is not a crucial factor. On the other hand, pickled steel sheets, with their smooth and clean surface, are commonly utilized in applications that demand a high-quality finish, such as automotive panels, appliances, and architectural elements. In conclusion, the primary disparity between a black steel sheet and a pickled steel sheet lies in their surface finish. A black steel sheet possesses a rough and scaly surface due to oxidation during hot rolling, while a pickled steel sheet exhibits a smooth and clean surface subsequent to undergoing a pickling process to eliminate the oxide scale.

- Q: How do steel sheets compare to stainless steel sheets in terms of corrosion resistance?

- Stainless steel sheets have superior corrosion resistance compared to steel sheets, thanks to the presence of chromium that forms a protective layer against corrosion.

- Q: Can steel sheets be used for storage racks?

- Yes, steel sheets can be used for storage racks. They are durable, strong, and can safely support heavy loads, making them an ideal material for storage rack construction.

- Q: What is the process of cold rolling steel sheets?

- The process of cold rolling steel sheets involves passing hot-rolled steel through a set of rollers at room temperature to reduce its thickness and improve its surface finish. This process is typically done in multiple passes, gradually reducing the thickness of the steel while maintaining its strength. Cold rolling also imparts desirable mechanical properties to the steel, such as increased hardness and improved dimensional accuracy.

Send your message to us

Plate Use for Boilers and Containers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords