Color Coated Pre-Painted Steel Coil in Yellow

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1:Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,degrease , chemical treatment and liquid dope with several layers of color ,then after fring and cooling ,finally become pre-painted galvanized/aluzinc steel with good capable of decoration,molding,corrosion resistance,superior workability,durability and weather resistance.

2:Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

Paint | Standard PE,PVDF,PU | Color | RAL Scale | Coil Weight | 3mt-7mt |

3:Packaging & Delivery

Packing: Export Standard Packing (full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips)

Delivery:30-45 Days

Detail Images:

Size can be customized

Financial support with max 180 days unsance L/C

Prime quanlity, competitive price

Fast delivery time.

4:PPGI / GI Steel Sheet

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Aluzinc Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Steel | TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

2) OUR SPECIFICATION OFPPGI/PPGL (Prepainted Galvanized/Aluzinc Steel Coils)

Thickness | Width | Length of plate | Inner diameter of coil | |

0.16-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Base plate | Available Coated Mass(g/m^2) |

Galvanized Steel | 80, 100, 120, 160, 180, 200, 275 |

Galvalume Steel | 50, 70, 150 ect. |

Available Painting OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 20+5microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

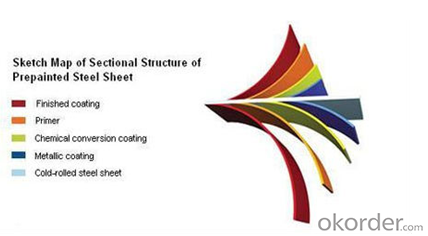

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

- Q: How are steel coils used in the production of gutters and downspouts?

- Steel coils are used in the production of gutters and downspouts as they are uncoiled and fed into a roll-forming machine. This machine shapes and cuts the steel into the desired gutter or downspout profiles. The steel coils provide the necessary raw material for creating durable and long-lasting gutters and downspouts that effectively channel rainwater away from buildings.

- Q: How are steel coils used in the manufacturing of structural components?

- Steel coils are used in the manufacturing of structural components as they are typically used to form and shape various structural elements such as beams, columns, and trusses. These coils are unwound, flattened, and then processed through a series of machinery to be cut, shaped, and welded into the desired structural component. The steel coils provide a reliable and strong material base for the manufacturing process, ensuring the durability and stability of the final structural components.

- Q: Does anyone know the lyrics to steel driving man by Dailey and Vincent. I would really appreciate it

- watch man of steel full movie online free adf.ly/dfxYD

- Q: I am making a sword of 1060 carbon steel and would like to know how to heat treat it once it's ready, could anyone help please?

- Heat treating easy, HA! It is the most critical part of bladesmithing. Done wrong and all those hours of work go up in smoke (or a snap of the steel). You'll need a bucket of oil, preferably one that is deep enough to go in point first. If not you'll have to go in edge first, not recommended on a double edged blade, ok for single edge. You'll need to build a charcoal fire long enough for the blade. You will need to blow air under the fire to get it hot enough, the challenge is getting the heat even. You get the fire going and established, put the blade in turning it back and forth (if you keep turning it in the same direction when it heats up you could work a twist in it). When it starts turning red pull it out and touch it with a magnet, if the magnet sticks put it back. Keep heating and repeating until the magnet no longer sticks. Heat a little more, then quench rapidly point first. Don't let the blade lean to one side as warpage will occur. When it cools enough to touch, check with a file. If the doesn't file cut then you've properly hardened the steel and it's ready for temper. Now comes the really hard part. Grind the scale off carefully,preferably with a side grinder with a flap wheel. I've had hard wheel break freshly hardened blades. After cleaning you'll need to put it in an oven (preferred) or use a torch and carefully heat the blade. Watch the temper colors (oven temp 500-550F) or with the torch as the steel turns colors blue to purple for a double edged weapon. Any warpage that occurs needs to be worked out at temping temp.

- Q: hello guys. im totally new to this metalwork things. i need to do it for my project. i need to join stainless steel wires to build some kind of structure (eiffel tow. for example).i already have the wire and the torch. now the question is: where do i get silver solder? is it expensive? and what is flux for? is it necessary? what does it do? is it expensive?thank u for ur time guys! :)

- You can buy it on Ebay . The flux cleans the surface so the solder will stick . Check with a welding supply to see if this process will work on stainless.

- Q: Can steel coils be cut or trimmed after delivery?

- Yes, steel coils can be cut or trimmed after delivery. Steel coils are typically delivered in large sizes and can be easily cut or trimmed to the desired length or shape using various cutting methods such as shearing, slitting, or laser cutting.

- Q: They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

- Q: The length of a steel beam increases by 0.78 mm when its temperature is raised from 22 degrees C to 35 degrees C. What is the length of the beam at 22 degrees C (in meters)?I used: L = (0.78 mm)/[(9/5)(.00000645 F)(13)] = 5.17 meters but Mastering Physics said Not quite. Check through your calculations; you may have made a rounding error or used the wrong number of significant figures. I'm confused because this is how we learned this kind of problem in class, so if anybody knows what I did wrong, feel free to correct my errors! Thanks

- we may use the formula ΔL=α(Lo)(Tf-To) where Lf is the length of steel at temp. Tf Lo is length at To α is the coefficient of linear expansion of steel which is 11x10^-6/°C ΔL=0.78mm (the change in length) Lo=? ΔL=α(Lo)(Tf-To) Lo=ΔL/[α(Tf-To)] Lo=(0.78x10^-3m)/[(11x10^-6/°C)(35°C-2...? Lo=5.455m answer

- Q: I just started playing guitar last year. I never changed the chords. When my sister started taking guitar lessons her teacher said that she needed to change the chords. When i bought the guitar it came with steel strings but i bought nylon strings because they are easier on the fingers. The problem is i already tuned up the guitar but it sounds really bad like if it was not tuned. What can i do about this?

- Guitars okorder /

- Q: How are steel coils used in the production of household appliances?

- Steel coils are used in the production of household appliances as they are a primary material for manufacturing various components like frames, panels, and cabinets. The coils are typically processed and formed into the desired shapes, providing strength, durability, and structural stability to appliances such as refrigerators, washers, dryers, and ovens.

Send your message to us

Color Coated Pre-Painted Steel Coil in Yellow

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords