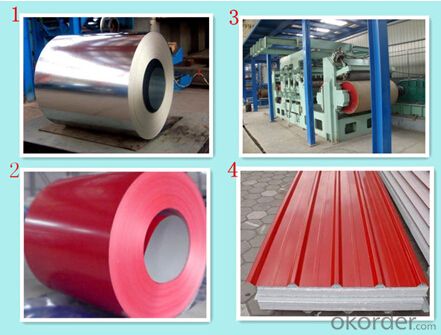

Hot Rolled Color Coated Pre-Painted Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

description:

Model NO.:thickness 0.15-0.8mm

Type:Steel Plate

Technique:Cold Rolled

Certification:ISO, SGS

Standard:ASTM, GB, JIS

Stock:Stock

Surface Treatment:Coated

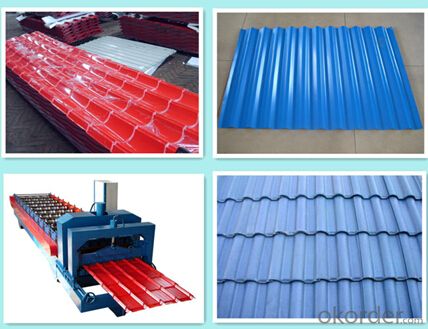

Special Use:Roofing

PPGI/ PPGL:Width: 610/724/820/914/1000/1200/1219/1220/1250mm

Thicness:0.13mm-0.8mm

Width:610mm-1250mm

Zinc Coating:Az40-150, Z40-275G/M2

Paint Coat:Front 5+15 Back 5-7um

ID:508mm

Spangle:Regular/Mini/Zero/Big

Surface:Chromed/Dry/Unoil or Oil/Anti-Figer

Export Markets:North America, South America, Eastern Europe, Southeast Asia, Africa, Mid East, Eastern Asia

Product Description

1.Pre-painted Galvanized corrugated steel sheet general information

1.Thickness:0.13mm to2.0mm

2.Length: 1m to 11.8m.

3. Color: navy blue,white grey and any RAL colors.

4. Certification: ISO9001:2000.

5.Material : cold rolled galvanized steel coil.

6. Standard: JIS,DX51D,SGCC,Q235.

7. advantage: waterproof,light weight, high strength,best price.

8. HS code: 7210700000

9. usage: it is used as the roofing of the house.

| Back painting: | 5-7 mic. EP |

| Color: | According to RAL standard |

| commodity | Color-coated Galvanized Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Thickness | 0.14-1.0mm(0.16-0.8mm is the most advantage thickness)) |

| Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z60-150g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

- Q: I bought stainless steel appliances a year ago. I have two kids who like to put their hands all over the fridge and they always leave dirty marks all over it. I bought stainless steel cleaner but it doesn't do a good enough job. Anyone know any other cleaning remedies?

- You can try Stainless Steel wipes. Weiman is a good brand

- Q: I went to the store to get metal to make a knife and they had weldable steel and plate steel. Which one would be best/ which steels would be best for what i want to do?

- Weldable steel is a generic term for steel with low carbon content which makes it easy to weld, form, and machine. If you're looking for a knife blade material, you need either a stainless steel or a high carbon steel which is not at all weldable. The more carbon in steel, the better it responds to heat treatment like hardening, tempering, etc. Plus, the high carbon steel will hold an edge better. Hope this helped.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide strength and durability to the ducts. These coils are shaped and formed into the desired ductwork design, providing a rigid structure that can withstand the pressure and movement of air. The steel coils also ensure that the ductwork maintains its shape over time, preventing any deformation or collapse.

- Q: is a 1962 steel penny worth anything?

- 1962 D Penny

- Q: Can steel coils be coated with RFID technology?

- Yes, steel coils can be coated with RFID technology. This technology allows for tracking and identification of the steel coils, improving supply chain management and providing real-time information on their location and status.

- Q: What are the different methods of cut-to-length shearing for steel coils?

- There are several methods of cut-to-length shearing for steel coils, each with its own advantages and applications. Some of the commonly used methods are: 1. Rotary Shearing: This method involves the use of a rotating shear blade that cuts through the coil. It offers high precision and can handle a wide range of material thicknesses. Rotary shearing is suitable for high-volume production and can achieve high cutting speeds. 2. Guillotine Shearing: In this method, a straight blade is used to cut through the coil. It is a versatile method that can handle various material thicknesses and widths. Guillotine shearing is relatively simple and efficient, making it a popular choice for many applications. 3. Slitting: Slitting involves making multiple longitudinal cuts in the coil to create narrower strips. It is commonly used when a coil needs to be divided into several smaller coils or when narrower strips are required for specific applications. Slitting can be done using either rotary or straight blades. 4. Laser Cutting: Laser cutting utilizes a high-powered laser beam to melt or vaporize the material, resulting in a clean and precise cut. It is ideal for cutting complex shapes or patterns and can handle both thin and thick steel coils. Laser cutting offers high accuracy and minimal material distortion. 5. Waterjet Cutting: Waterjet cutting uses a high-pressure stream of water mixed with abrasive particles to cut through the coil. This method is suitable for a wide range of materials, including steel, and can achieve high accuracy. Waterjet cutting is often used for cutting thick coils or when heat-affected zones need to be minimized. Each method has its own strengths and limitations, and the choice depends on factors such as material thickness, required precision, production volume, and specific application requirements. The selection of the most appropriate method is crucial to ensure efficient and high-quality cut-to-length shearing for steel coils.

- Q: What is the difference between hot-rolled and cold-rolled steel coils?

- The main difference between hot-rolled and cold-rolled steel coils lies in the production process. Hot-rolled steel coils are made by heating the steel above its recrystallization temperature, causing it to become malleable and allowing it to be rolled into the desired shape. This process results in a thicker and less precise product with a rough surface. On the other hand, cold-rolled steel coils are made by cooling the hot-rolled steel and then passing it through rollers at room temperature. This process enhances the steel's strength, durability, and dimensional accuracy, resulting in a thinner and smoother product that is ideal for applications requiring precision.

- Q: We have a stain from a pot or bowl in our new expensive stainless steel sink. It looks like a water mark that happens when you leave a glass on a table without a coaster. It's a mark in the shape of the bowl or pot that was there. We left it there overnight:( It's not rust either. Help!

- use bar keepers like some recommended , then polish with pledge furniture polish, sounds weird, but it brings back the luster to stainless and helps prevent marks if you do it again, wipe down dry and use a rag with pledge every time you finish in the kitchen to keep your sink beautiful for years to come

- Q: I'm in the middle of a remodel and buying appliances. Is there any way to ensure that the stainless steel is the same tone if you get different brands?

- Stainless steel is pretty much stainless steel. The differences in tone you can get is when you get stainless steel look appliances. They tend to be a bit more like a charcoal color than true stainless steel color. When I bought my house, it had a stainless steel GE microwave, dishwasher, and stove, and a Braun stainless steel range hood. When we remodeled last year, we got a Maytag Ice20 stainless steel refrigerator and a Kholer stainless steel sink. They all look fine together.

- Q: Can steel coils be used in the production of HVAC systems?

- Yes, steel coils can be used in the production of HVAC (heating, ventilation, and air conditioning) systems. Steel coils are commonly used in the manufacturing of HVAC equipment such as air handlers, condenser coils, evaporator coils, and heat exchangers. Steel coils provide durability and strength, making them suitable for withstanding the high pressures and temperatures involved in HVAC operations. Additionally, steel coils offer good heat transfer properties, allowing for efficient heat exchange between the refrigerant and the air being conditioned. Overall, steel coils are a reliable and commonly used component in the production of HVAC systems.

Send your message to us

Hot Rolled Color Coated Pre-Painted Steel Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords