Pre-painted Galvanized Steel Coil Color Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

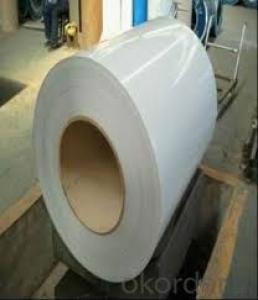

1.Introduction of Prepainted Galvanized Steel Coil:

Galvanized steel coil is a special type of steel coil used in a number of different applications within fabrication and manufacturing environments. Steel coil of any kind is flat stock that is thin enough to be rolled into a coil or wound into a continuous roll.

2.Usages of Prepainted Galvanized Steel Coil:

With excellent cold bending molded manufacturability, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

3.Prepainted Galvanized Steel Images:

4.Galvanized Steel Specification:

Galvanized steel coils | ||

Brand Name: | GANGZHENG Steel | |

Standard: | ASTM;EN;GB;JIS;A755M | |

Grade: | CGLCC /CGCC | |

Size: | Thickness: | 0.14-0.8mm |

Width: | 600mm-1250mm | |

Length: | Coil or Customer's requirement | |

Base plate: | galvanized steel coils | |

Color: | RAL color or according to the sample | |

Coil ID: | 508mm / 610mm | |

Coil Weight: | any tons or client’s requirements | |

Type : | coil or sheets | |

5.Our Factory:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: I have a steel plate 3' long x 2 wide x 3/16 thick. I have a 1/2 diameter hole with the center 3/4 from the end. Tensile strength is 38,000psi. A chain goes through the hole and is connected to a load. how does one determine how much tension the chain can have before it rips through the hole?

- oo that's a tough one. dont remember... just finished that class...sorry

- Q: What are the common methods of joining steel coils?

- Various techniques can be employed to join steel coils, depending on the desired outcome and specific application. Butt welding is a commonly utilized method wherein the two ends of the steel coils are aligned and welded together. Gas welding, electric resistance welding, or laser welding can be employed for this purpose. This technique yields a strong and continuous joint without the need for additional material. For temporary or low-stress applications where disassembly may be necessary, overlapping and stitching is an option. In this technique, one end of the steel coil is overlapped onto the other end and fastened together using mechanical means such as staples, nails, or screws. Mechanical couplings are another means of joining steel coils. These couplings are designed to fit over the coil ends and securely hold them together. They are commonly used in pipelines where the joint must be leak-proof and capable of withstanding high pressure. Adhesive bonding is a method that involves applying a suitable adhesive or bonding agent to the coil ends and pressing them together. This technique results in a clean and visually appealing joint, although the strength may vary depending on the adhesive used. Similar to overlapping and stitching, overlapping and welding involves overlapping the coil ends and welding them together. However, instead of using mechanical fasteners, welding is employed to create a stronger and more permanent joint. This method is frequently employed in structural applications that require high strength and durability. It should be noted that the selection of a joining method depends on factors such as the type of steel, application requirements, and desired joint strength. Careful consideration should be given to ensure that the chosen method is suitable for the specific project.

- Q: How are steel coils used in the production of metal panels?

- Steel coils are used in the production of metal panels as the primary raw material. These coils are fed into a roll forming machine, where they are uncoiled, flattened, and then shaped into the desired panel profiles. This process allows for efficient and continuous production of metal panels with consistent quality and strength.

- Q: What are the different steel coil specifications?

- There are several different steel coil specifications available, including dimensions, thickness, width, and weight. These specifications vary depending on the specific application and industry requirements. Additionally, steel coils can be classified based on their surface finish, such as hot-rolled, cold-rolled, or galvanized.

- Q: How are steel coils used in the manufacturing of power transmission towers?

- Steel coils are used in the manufacturing of power transmission towers by being cut, shaped, and welded together to form the structural components of the towers. The coils provide a strong and durable material that can withstand the weight and stress of the tower, ensuring its stability and longevity.

- Q: How are steel coils used in the production of automotive body panels?

- Steel coils are used in the production of automotive body panels by being processed and shaped into the desired form through techniques like stamping, cutting, and bending. These coils provide the necessary strength and durability required for the structural integrity of the body panels, ensuring the safety and performance of the vehicle.

- Q: How do steel coils compare to stainless steel coils?

- Steel coils and stainless steel coils find extensive use in various industries due to their robustness and durability. Nevertheless, selecting the appropriate material necessitates considering some essential distinctions between the two. One of the primary disparities lies in the composition of the materials. Steel coils, primarily comprising iron and carbon, incorporate additional elements to enhance specific properties. Conversely, stainless steel coils contain iron, carbon, and a substantial amount of chromium, which imparts them with distinctive corrosion-resistant attributes. Owing to the presence of chromium, stainless steel coils outperform regular steel coils in their resistance to corrosion, tarnishing, and rust. This renders stainless steel coils highly suitable for applications within environments characterized by elevated humidity, moisture, or exposure to corrosive substances. On the contrary, steel coils are more susceptible to rust and may necessitate supplementary protective coatings or treatments to avert corrosion. Another notable differentiation concerns the visual appearance of the two materials. Stainless steel coils boast a lustrous and reflective surface, endowing them with an aesthetically pleasing allure. They commonly find application in contexts where appearance holds significance, such as kitchen appliances, architectural structures, or decorative purposes. Conversely, steel coils exhibit a matte or dull finish and are frequently employed in industrial applications where visual aesthetics are of secondary concern. In terms of strength, both steel and stainless steel coils exhibit excellent mechanical properties. However, stainless steel coils generally demonstrate greater tensile strength and enhanced resistance to high temperatures. Consequently, they prove well-suited for applications necessitating strength, such as the construction, automotive, or aerospace industries. Lastly, cost represents a factor warranting consideration while comparing steel coils to stainless steel coils. Steel coils generally offer a more cost-effective option due to the lower expense of raw materials and simpler manufacturing processes. Nevertheless, when factoring in the added value of corrosion resistance and longevity, stainless steel coils may emerge as a more economical choice in the long run, requiring less maintenance and replacement. To conclude, steel coils and stainless steel coils possess distinct properties and characteristics, rendering them suitable for specific applications. Stainless steel coils exhibit superior corrosion resistance, a glossy appearance, and heightened tensile strength, while steel coils prove more cost-effective. Ultimately, the selection between the two hinges on the precise requirements of the application, encompassing factors such as the environment, aesthetics, strength, and budget.

- Q: How do steel coil manufacturers contribute to local economies?

- Steel coil manufacturers contribute to local economies in several ways. Firstly, they create employment opportunities by hiring a significant number of workers, thereby reducing unemployment rates and improving the standard of living in the community. These jobs often include a range of skill levels, from entry-level positions to highly specialized roles, providing a diverse range of employment options for locals. Additionally, steel coil manufacturers contribute to the local economy through their supply chain. They typically rely on local suppliers for raw materials, transportation services, and various support services, fostering business relationships and boosting the local economy. This leads to increased revenue for these suppliers and stimulates economic growth in the region. Moreover, the presence of steel coil manufacturers can attract other businesses to the area, such as logistics companies, distributors, and machine shops, which further enhances the local economy. This expansion of the industrial sector can result in a multiplier effect, generating additional job opportunities and attracting investment from outside the community. Lastly, steel coil manufacturers often engage in corporate social responsibility initiatives, such as supporting local charities, sponsoring community events, or investing in infrastructure development. These contributions not only have a positive social impact but also contribute to the overall economic development and well-being of the local community. In summary, steel coil manufacturers play a crucial role in local economies by creating jobs, stimulating the supply chain, attracting businesses, and investing in community development, all of which contribute to the growth and prosperity of the region.

- Q: How are steel coils used in the production of storage systems?

- Steel coils are used in the production of storage systems as they are transformed into various components such as beams, columns, and shelves. These components are then assembled to create the framework and structure of the storage systems, providing strength, stability, and durability to store items efficiently.

Send your message to us

Pre-painted Galvanized Steel Coil Color Coated

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords