Pre-Painted Galvanized Steel Sheet,Coil with High Quality Yellow Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

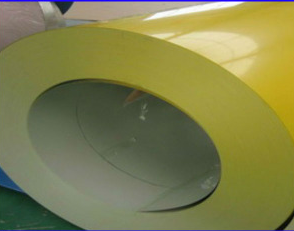

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How do steel coils contribute to the construction sector?

- Steel coils contribute to the construction sector in several ways. Firstly, they are used to manufacture structural components such as beams, columns, and steel frames, which provide strength and support to buildings and infrastructure. Secondly, steel coils are used to produce reinforcement bars that are embedded in concrete, enhancing its tensile strength and durability. Additionally, steel coils are utilized in the construction of bridges, pipelines, and other large-scale projects that require robust and long-lasting materials. Overall, steel coils play a vital role in the construction sector by providing the necessary materials for sturdy and resilient structures.

- Q: How are steel coils coated?

- Steel coils are typically coated through a process known as coil coating, which involves applying a protective layer to the surface of the steel. This is done by passing the coil through a series of rollers that apply the coating material evenly across the entire surface. The coating can be applied using various methods such as roll coating, spray coating, or electrostatic coating, depending on the desired finish and properties. The coated steel coils are then cured or baked to ensure the coating adheres properly and provides the desired level of protection and durability.

- Q: What are the different types of steel alloys used in coils?

- There are several different types of steel alloys commonly used in coils, each with its own unique properties and characteristics. Some of the most common types include: 1. Carbon Steel: This is the most basic and widely used type of steel alloy in coils. It contains a low amount of carbon and is known for its strength and durability. Carbon steel coils are often used in applications where high strength is required, such as automotive parts, construction materials, and machinery components. 2. Stainless Steel: Stainless steel coils are made from an alloy of iron, chromium, and other elements. They are highly corrosion-resistant and have excellent strength and heat resistance properties. Stainless steel coils are commonly used in applications where resistance to corrosion and staining is important, such as kitchen appliances, medical equipment, and transportation components. 3. Galvanized Steel: Galvanized steel coils are made by coating regular carbon steel with a layer of zinc. This coating provides excellent corrosion resistance and protects the underlying steel from rusting. Galvanized steel coils are commonly used in outdoor applications, such as roofing, fencing, and automotive body parts. 4. Alloy Steel: Alloy steel coils are made by adding various alloying elements, such as manganese, nickel, chromium, or molybdenum, to carbon steel. This enhances the strength, hardness, and wear resistance of the steel. Alloy steel coils are often used in applications where high strength and toughness are required, such as in the manufacturing of machinery, tools, and construction equipment. 5. Electrical Steel: Electrical steel coils are specifically designed for use in electrical equipment, such as transformers and electric motors. They have low electrical resistance and high magnetic permeability, allowing them to efficiently conduct electricity and create magnetic fields. Electrical steel coils are typically made from a silicon alloy, which improves their electrical and magnetic properties. Overall, the choice of steel alloy for coils depends on the specific requirements of the application, such as strength, corrosion resistance, electrical conductivity, or heat resistance.

- Q: What are the challenges in coil slitting?

- Coil slitting, also known as coil cutting, involves the process of cutting large metal coils into narrower strips. However, there are several challenges associated with this process. One challenge is maintaining precision during slitting, as any deviation can result in uneven strip widths or poor edge quality. Another challenge is managing the tension of the coil throughout the slitting process to prevent material distortion or breakage. Additionally, handling and transporting the slit coils can be challenging due to their length and weight. Overall, ensuring accuracy, maintaining proper tension, and effectively handling the slit coils are some of the key challenges faced in coil slitting.

- Q: How long do steel coils last?

- The lifespan of steel coils can vary depending on several factors, including usage, maintenance, and environmental conditions. However, with proper care and regular maintenance, steel coils can typically last for several decades.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q: I know there is soft steel and sturdier steel they use in products. The sturdier often used for equipment that requires more durability when in operation.

- It kind of depends on the application. It can be anywhere from simple to very difficult depending on what exactly you are talking about. Hardening a small piece of carbon tool steel for a chisel or punch consists of simply heating it till its red hot and then quenching it in water. This is done after the tool is formed. Hardening also means making the steel brittle, so it must be tempered after hardening to make it hard and strong. Hardening large or huge pieces like that used for equipment is done at the foundry, where they have equipment to do such a job.

- Q: Steels like YHB-2, MVS-8, and SK-5. Also if you know anything about these steels that would be helpful.

- White steel is a common shorthand name for white paper steel (shirogami hagane) which can be any of several fairly simple high carbon, water hardening steel grades. The carbon content varies by grade, and runs from 0.8 to 1.4%. The range of carbon content within a grade is a tight 0.1%. For example, the carbon content of Shirogami Hagani No1A is specified to be between 1.3 and 1.4%. Each grade also contains 0.1-0.2% silicon and 0.2-0.3% manganese, and only trace amounts of the impurities sulfur and phosphorus. Blue paper steel (aogami hagane) is also offered in several grades, with carbon content ranging similarly to the white grades. However, blue steel contains the additional alloying elements chromium and tungsten, and one grade (aogami super) also contains molybdenum and vanadium. The blue steels can be quenched in water or oil, whereas most of the white grades need a faster quench and require water.

- Q: What are the applications of steel coils in automotive manufacturing?

- Steel coils have a wide range of applications in automotive manufacturing due to their unique properties and characteristics. They are commonly used in various parts and components of vehicles, offering numerous benefits and contributing to the overall performance, safety, and reliability of automobiles. One of the primary applications of steel coils in automotive manufacturing is in the production of body panels. Steel coils are used to create the outer body structure of vehicles, including doors, hoods, fenders, and roofs. The high strength and durability of steel make it an ideal material for these components, as it provides protection against impacts and enhances the overall structural integrity of the vehicle. Steel coils are also used in the manufacturing of automotive chassis and frames. The strong and rigid nature of steel makes it an excellent choice for these critical components, as it can withstand heavy loads and provide stability to the vehicle. Steel coils ensure that the chassis and frames have the necessary strength and stiffness to support the weight of the vehicle and withstand the forces experienced during driving. Moreover, steel coils are utilized in the production of various suspension and steering components, such as springs, stabilizer bars, and control arms. These components require high strength and resistance to fatigue, as they are subjected to constant stress and vibrations. Steel coils provide the necessary toughness and flexibility to these parts, ensuring smooth and controlled vehicle handling. In addition, steel coils are used in the manufacturing of engine parts and exhaust systems. The high-temperature resistance and corrosion resistance of steel make it an ideal material for these applications. Steel coils are formed into various shapes, such as tubes and pipes, and used to create exhaust manifolds, catalytic converters, and mufflers. They play a crucial role in improving the performance and efficiency of the engine, as well as reducing harmful emissions. Overall, steel coils are vital in automotive manufacturing due to their strength, durability, and versatility. They are used in the production of body panels, chassis, suspension components, engine parts, and exhaust systems. The use of steel coils in these applications ensures that vehicles are safe, reliable, and perform optimally, making them an indispensable material in the automotive industry.

- Q: How are steel coils coated to prevent rust and corrosion?

- Steel coils are coated to prevent rust and corrosion through a process called galvanization. This involves immersing the coils in a bath of molten zinc, which forms a protective layer on the steel surface. This zinc coating acts as a barrier, preventing oxygen and moisture from coming into contact with the steel, thus reducing the risk of rust and corrosion.

Send your message to us

Pre-Painted Galvanized Steel Sheet,Coil with High Quality Yellow Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords