Color Coated PPGI Steel Coil or Steel Sheet in High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

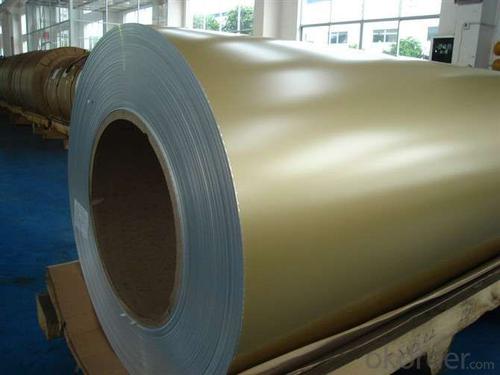

1.Structure of Color Coated GI/GL Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Color Coated GI/GL Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Color Coated GI/GL Steel Coil Images

4.Pre-painted GI/GL Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Color Coated GI/GL Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is it possible to have a 25 room Hotel building with Steel structure. Thay is instead of traditional RCC can we have a 25 room hotel constructed using steel construction? Is it economic and how much time will it take to construct the same? Appraximate area would be 5000sq.ft to 10000sqft.

- Yes you can have a steel structure building, as if it is more economical than RCC, I think it is , and it is much faster in completion than RCC, For such area steel structure is less in time than the RCC by 30% to 40%, my experience could estimate 6months to 8 months duration for steel structure

- Q: For some reason, if you rub iron oxide or lodestone (both very crumbly, dark, mineral-like materials) into soft, unhardened steel, their particles actually get stuck into the surface of the steel (that is, darkening it). My question is, how does this work? How come iron oxide and lodestone can get stuck, and how come other materials (like silicone carbide, for example) do not?My second question is, are there any materials that can get stuck into steel, that is also blue in color, and how would I best obtain it?

- Funny! 100!

- Q: How are steel coils used in the production of steel locks?

- Steel coils are used in the production of steel locks as they provide the raw material needed for manufacturing lock components such as lock bodies, shackle, and tumblers. The steel coils are processed and shaped into various lock parts, which are then assembled to create the final product.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using heavy-duty cranes and specialized equipment. When loading, the coils are lifted from the dockside or storage area using a crane with strong lifting capacity. They are carefully positioned onto the ship's deck, ensuring proper balance and securement to prevent any damage during transit. Unloading is done in a similar manner, with the crane carefully lifting the coils from the ship's deck and placing them onto the dock or designated storage area. Throughout the process, safety protocols are followed to ensure the smooth and efficient handling of these heavy and valuable cargo.

- Q: What are the different types of steel coatings for coil protection?

- There are several different types of steel coatings for coil protection, including galvanized coatings, zinc-nickel coatings, organic coatings, and metallic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface to protect it from corrosion. Zinc-nickel coatings offer enhanced corrosion resistance and improved adhesion properties compared to traditional galvanized coatings. Organic coatings, such as paint or polymer coatings, provide a protective barrier against corrosion and can also offer aesthetic benefits. Metallic coatings involve applying a thin layer of a different metal, such as aluminum or tin, to the steel surface to provide corrosion resistance.

- Q: How are steel coils used in the production of metal shelving?

- Steel coils are an essential component in the production of metal shelving. These coils, which are made from high-quality steel, undergo a series of manufacturing processes to transform them into sturdy and durable shelves. Firstly, the steel coils are unwound and flattened to the desired thickness using a machine called a slitter. This process ensures that the coils are of uniform size and thickness, which is crucial for producing consistent and reliable shelves. Next, the flattened steel is cut into specific lengths using a shear. These cut-to-size pieces are then sent to a press brake, where they are bent and shaped into the desired shelf design. The press brake applies pressure to the metal, allowing it to be folded or formed into different angles and shapes, such as shelves with raised edges or adjustable brackets. Once the shelves have been formed, they go through a process called welding, where any joints or seams are securely fused together. This welding process ensures the structural integrity of the shelves, making them capable of supporting heavy loads and maintaining their shape over time. After welding, the shelves undergo surface treatment to enhance their appearance and protect them from corrosion. This can include processes such as cleaning, sandblasting, and painting. The surface treatment not only improves the aesthetic appeal of the shelves but also extends their lifespan by preventing rust and other forms of deterioration. Finally, the shelves are inspected for quality control to ensure that they meet the necessary standards. This includes checking for any defects, measuring dimensions, and conducting load-bearing tests to ensure the shelves are capable of withstanding the intended weight capacity. In summary, steel coils are used in the production of metal shelving by being unwound, flattened, cut, bent, welded, treated, and inspected. These coils provide the raw material necessary to create strong, durable, and aesthetically pleasing shelves that can be used in various settings such as warehouses, retail stores, and homes.

- Q: What are the different types of steel coil grades?

- Various industries and applications utilize a range of steel coil grades. Some commonly employed types include: 1. Carbon Steel: This fundamental steel variant consists primarily of iron and carbon. Its widespread use in construction, automotive, and manufacturing industries stems from its exceptional strength and durability. 2. Stainless Steel: This specific steel variant incorporates chromium, which imparts corrosion resistance, making it appropriate for applications requiring protection against oxidation and staining. Industries such as food processing, chemical, and medical frequently employ stainless steel. 3. High-Strength Low-Alloy (HSLA) Steel: HSLA steel comprises trace amounts of alloying elements like copper, phosphorus, niobium, and vanadium. This steel variant offers superior strength and improved mechanical properties when compared to carbon steel, rendering it suitable for structural applications. 4. Galvanized Steel: This type of steel undergoes a zinc coating process to safeguard against corrosion. Galvanized steel finds common use in outdoor applications like roofing, fencing, and automotive components. 5. Electrical Steel: Also known as silicon steel, electrical steel possesses high magnetic permeability, low electrical conductivity, and minimal core loss. It finds application in the production of transformers, motors, and other electrical equipment. 6. Tool Steel: Tool steel, a high-carbon steel variant, is specifically engineered for fabricating tools and dies. Its outstanding hardness, wear resistance, and toughness make it appropriate for cutting, forming, and shaping materials. These examples represent merely a fraction of the available steel coil grades. Each grade exhibits its own distinct properties and characteristics, rendering it suitable for specific applications within various industries.

- Q: Why can't you use a lead shot only choke with steel shot or a steel shot only choke with lead shot? I have used a lead only choke with steel shot and my shotgun shot fine and there was no damage to the choke.

- The reasoning behind lead shot only is that those chokes (usually) have a very tight constriction. It can cause severe and dangerous pressure spikes when a charge of steel shot (almost impossible to compress compared to lead) gets slammed through them. Another reason could be that the tubes are either very soft steel or very thin and steel shot will damage them quickly. I personally haven't seen any steel shot ONLY tubes before just ones marked for lead and/or steel or ok for steel shot.

- Q: Perform three sets of 15 repetitions several times a week and you will soon have buns of steel.

- Means you will have a nice booty, but the true question is... What does Buns of Steel mean by several times and SOON? Good luck.

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are transformed into structural components such as beams, plates, and girders. These coils are processed and shaped into the desired forms, providing the necessary strength and durability for the bridge's construction.

Send your message to us

Color Coated PPGI Steel Coil or Steel Sheet in High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords