Color Coated Galvanized Steel Coils PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Surface Treatment:Coated

Technique:Galvanized

Standard:JIS

Application:Container Plate

Edge:Mill

Stock:Stock

Steel Grade:CGCC, Dx51d, SGCC

Color:Ral 1015, 5002, 6005, 8017, 9002, 9006, 9010 etc.

Thickness:0.16-1.0mm

Width:914/1000/1200/1219/1220/1250mm

Base Metal:Galvanized or Galvalume Steel

Zinc-Coating:Z50-150G/M2 or Az40-100G/M2

ID Coil:508mm

Coil Weight:3-5 Mt

Painting:20-25miu on Top / 5-8miu on Back

Type of Coating:PE Smp PVDF

Export Markets:North America, South America, Southeast Asia, Eastern Asia

Additional Info.

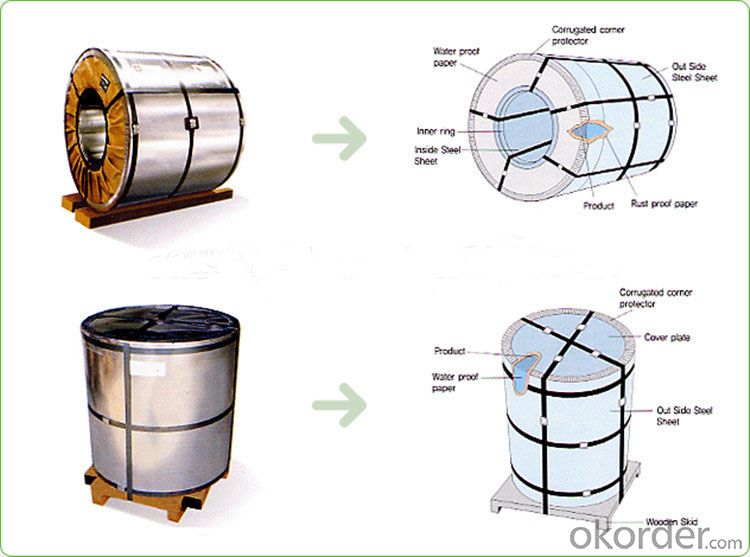

Packing:Standard Export Seaworthy Packing In20′′ Container

Standard:0.14-1.0*914-1250*C

Origin:China

HS Code:72107010

Production Capacity:100000tons Per Year

Product Description

Color-coated Galvanized/Galvalume Steel Coil (PPGI/PPGL)

1. Techinical standard: EN10169

2. Grade: TDX51D, TSGCC

3. Color: Ral standard or according to customers' requirment

4. Thickness: 0.14-1.0mm (0.16-0.8mm is the most advantage thickness)

5. Width: 600-1250mm (610/724/820/914/1000/1200/1219/1220/1250mm)

6. Base metal: Galvanized / galvalume steel

7. Finish Painting: 15-20miu PE on top 5-8miu EP on back

8. Color: Ral standard

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: What are the different types of steel coil surface coatings?

- There are several different types of steel coil surface coatings that are used to enhance the durability, corrosion resistance, and aesthetic appearance of the steel. Some of the commonly used coatings include: 1. Zinc Coatings: Zinc coatings are widely used to protect steel from corrosion. Galvanized steel coils are coated with a layer of zinc to provide a barrier against moisture and other environmental elements. 2. Galvannealed Coatings: Galvannealed coatings are a combination of zinc and iron. This coating provides enhanced corrosion resistance and also improves paint adhesion, making it suitable for applications where painting is required. 3. Aluminum Coatings: Aluminum coatings are used to provide a lightweight and corrosion-resistant surface. Aluminum-coated steel coils are often used in the automotive industry for body panels and other parts that require high strength and resistance to corrosion. 4. Organic Coatings: Organic coatings are typically applied as a layer of paint or powder coating. These coatings provide protection against corrosion and also offer a wide range of color options for aesthetic purposes. They are commonly used in the construction industry for roofing and cladding applications. 5. Metallic Coatings: Metallic coatings such as tin, nickel, and chromium can be applied to steel coils to provide specific properties like improved electrical conductivity, increased hardness, or enhanced resistance to wear and tear. 6. Ceramic Coatings: Ceramic coatings are used to provide high-temperature resistance and thermal barrier properties. They are often used in applications where steel coils are exposed to extreme heat or in industrial processes that require thermal insulation. Each type of coating has its own unique properties and advantages, and the choice of coating depends on the specific requirements of the application. Manufacturers and engineers carefully consider factors such as cost, durability, corrosion resistance, and aesthetic appeal when selecting the appropriate coating for steel coils.

- Q: Are steel coils affected by magnetic fields?

- Yes, steel coils can be affected by magnetic fields. Steel is a ferromagnetic material, which means it can be magnetized or attracted to magnets. When a magnetic field is applied to a steel coil, it can induce a magnetic field within the coil, causing the coil to become magnetized. This can have several effects depending on the strength and duration of the magnetic field. If the magnetic field is strong and the coil is exposed to it for a significant amount of time, it can cause the steel coil to retain some magnetism even after the magnetic field is removed. This can be problematic in certain applications where a non-magnetic material is required, as the magnetized steel coil may attract or interfere with other nearby objects. On the other hand, if the magnetic field is rapidly changing or fluctuating, it can induce electrical currents within the steel coil through electromagnetic induction. These induced currents, known as eddy currents, can generate heat within the coil, leading to energy losses and potential damage to the coil. Therefore, it is important to consider the effects of magnetic fields on steel coils in various applications. Protective measures such as shielding or demagnetizing processes may be necessary to minimize the impact of magnetic fields on steel coils when required.

- Q: What is the weight of a steel coil?

- The weight of a steel coil can vary depending on its size and thickness. Generally, a steel coil can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: How are steel coils used in the production of storage shelves?

- Steel coils are a vital element in the manufacturing of storage shelves. Typically composed of carbon steel, these coils undergo various processes to achieve the desired form. To begin using steel coils for storage shelves, the coil must be unrolled and flattened. This operation is executed by a decoiler machine, which unwinds the coil and guides it through a series of rollers to flatten the metal. Once the coil is flattened, it is prepared for further processing. Following this, the flattened steel is cut into specific lengths using either a shearing machine or a saw. These cut pieces are then bent and shaped to fit the appropriate dimensions required for the storage shelves. The bending process is typically carried out using a press brake or a roll former, which applies pressure to the metal to achieve the desired shape. Once the steel has been shaped to the correct dimensions, it is welded together to form the structure of the storage shelf. This welding procedure guarantees the strength and durability of the shelves, enabling them to support heavy loads. Upon completion of the welding process, the storage shelves may undergo additional treatments to enhance their appearance and protect them against corrosion. These treatments can include processes like powder coating, galvanization, or painting. In summary, steel coils play an indispensable role in the production of storage shelves. They provide the essential raw material and their versatility allows for a wide range of shapes and sizes to be created. The strength and durability of steel make it the ideal choice for storage shelves, ensuring that they can endure heavy loads and provide long-lasting storage solutions.

- Q: What are the challenges in coil blanking?

- Coil blanking, a process used to cut flat metal sheets from coiled stock, presents several challenges that need to be addressed for efficient and accurate production. Some of the key challenges in coil blanking include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality. These variations can affect the cutting process and result in inconsistent blanks. Proper material selection and control are crucial to ensure consistent quality and dimensional accuracy. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature). These imperfections can cause alignment issues during the cutting process, leading to misalignment and inaccurate blanks. Specialized equipment and techniques, such as straighteners and leveling systems, are required to minimize these shape imperfections. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Adequate edge conditioning techniques, such as deburring or edge trimming, need to be employed to ensure clean and straight edges for the final blanks. 4. Slitting and shearing forces: The forces exerted during the coil blanking process can induce stresses and strains in the material, potentially leading to deformation or springback. These factors can result in dimensional variations and affect the overall quality of the finished blanks. Careful consideration of the slitting and shearing forces, along with proper tooling design and machine settings, is necessary to minimize these effects. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and minimizing material waste are critical challenges in coil blanking to optimize production efficiency and reduce costs. Efficient nesting algorithms and real-time monitoring systems can help optimize material utilization and minimize waste. 6. Automation and productivity: Coil blanking processes often require high-speed and high-volume production to meet market demands. Implementing automation systems, such as robotic material handling and advanced control systems, can enhance productivity. However, integrating and synchronizing these automation components with the cutting process can be challenging and requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking requires a combination of proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: How do steel coils contribute to the energy storage industry?

- The energy storage industry benefits greatly from the use of steel coils in multiple ways. Initially, steel coils are instrumental in the fabrication of energy storage systems like batteries. Through their steel casing, batteries are provided with both structural support and protection for the battery cells, ensuring their safety and longevity. If not for steel coils, batteries would be more susceptible to damage and unable to function efficiently. Furthermore, the construction of flywheels, an alternative form of energy storage technology, heavily relies on steel coils. Flywheels store energy by spinning a rotor at high speeds and releasing the stored energy when necessary. Steel coils are employed to create the rotor, which necessitates strength, durability, and the ability to withstand substantial rotational forces. Additionally, the magnetic properties of steel contribute to the enhancement of energy transfer efficiency within the flywheel system. Moreover, compressed air energy storage (CAES) systems also utilize steel coils in their production. CAES systems store energy by compressing air and releasing it to generate electricity upon demand. Steel coils are crucial in constructing the air storage chamber, guaranteeing its integrity and preventing any leakage or damage. The robust nature of steel coils makes them ideal for enduring the high pressures associated with the compression process. To summarize, the energy storage industry greatly benefits from the utilization of steel coils. They provide essential structural support, durability, and protection to various energy storage technologies, whether it be batteries, flywheels, or CAES systems. By contributing to the efficient and secure storage of energy, steel coils facilitate the advancement and adoption of sustainable energy solutions.

- Q: How many types of steel buildings are there?

- There are a number of designs which can be used to create different types of steel buildings as per the demands of the buyer or an investor. he various kinds of that can be constructed using steel are Homes, Hangars, Agriculture and Farm buildings for storage, Garages and Storage sheds, Open air sheds,, Barns, Arenas and stadiums, Automotive buildings with overhead doors and flexible framed openings, Religious buildings such as Churches and Temples, etc.

- Q: What are the common methods of joining steel coils together?

- Common methods of joining steel coils together include welding, mechanical fastening (such as using bolts or screws), adhesive bonding, and interlocking methods.

- Q: Why is the selection of steel building erector of extreme importance while starting a new steel building project?

- Steel building erectors play an important role as they are well versed with all the ups and downs of erecting a steel building and can prevent your construction project from unnecessary delays. There are lot of inexperienced steel building erectors in the market who can offer you their services at a much cheaper rate. Be cautious! It never works in the long run. A qualified steel building erector will always provide an initial professional insight of your project and cost effective solutions for your project.

- Q: So...that means Wolverine can stab him, right? Because Adamantite is stronger than steel. Correct?

- Faster than a Speeding bullet too!! They are just expressions/nicknames. Obviously he's faster than a speeding bullet, he can run from Kansas to Mexico and back and you wouldn't even know it. If you want it literally, just call him Superman, or extremely tough and fast man.

Send your message to us

Color Coated Galvanized Steel Coils PPGL

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords