STAINLESS STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

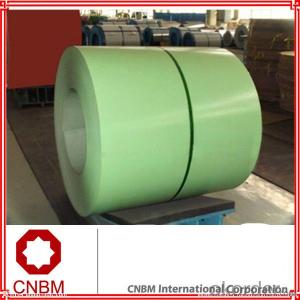

STAINLESS STEEL COILS

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

STAINLESS STEEL COILS

Technical Standard: Steel Grade &Standard:J1

Surface Treatment:NO.1

Hot rolled Annealed and Pickled(HRAP)

Grade: J1 , Prime quality

Mill Edge. No connection point in each coil.Component: Ni:1% , Cu: 0.65-0.9%, Cr: 13%, Mn: 10–12%, C: 0.09-0.12%

Package:Properly packed for ocean freight exportation in 20''container

Application::home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: What are the different methods of testing steel coils for quality control?

- There are several methods of testing steel coils for quality control, including visual inspection, dimensional measurement, chemical analysis, mechanical testing, and non-destructive testing. Visual inspection involves examining the surface of the coil for any defects or imperfections. Dimensional measurement ensures that the coil meets the specified size and thickness requirements. Chemical analysis involves testing the composition of the steel to ensure it meets the required standards. Mechanical testing involves assessing the strength, hardness, and other mechanical properties of the steel. Non-destructive testing methods, such as ultrasound or magnetic particle inspection, are used to detect internal defects or flaws in the coil without damaging it.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or recessed designs on a material's surface, and it can be done on various materials, including steel.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- Hello, the shutter door material mainly galvanized steel plate, color steel plate, aluminum alloy, stainless steel, PVC soft board, PVC soft door curtain.

- Q: Does anyone know if there is any info on Steel Manufacturing techniques, utilyzing electro/mechanical methods in order to create carbon nanotubes from the %C already inherant in the steel. In other words just modifying the Geometry of the Carbon the already makes up some of the steel.

- I don't think that would work. First off, there's not enough carbon in steel - even very high carbon steels are only about 2% carbon. Second, the iron atoms in steel form a crystal lattice, in the shape of a cube, with another iron atom in the middle of the cube. Each cube is about 0.3 nm per side. Carbon atoms work their way into the crystals and displace the iron atoms. But a carbon nanotube is around 1 nanometer in diameter - that's 3 times as big as the iron lattice! So a nanotube wouldn't fit. One thing you might do, however, is make a composite - mix the materials together on a scale a little bigger than the atomic scale that the iron and carbon mix to make steel. Just like a carbon fiber bicycle frame or ski pole is strands of carbon (much bigger and not as strong as nanotubes) held together with epoxy, you could hold nanotube strands together with metal. Not sure it would be good for armor, but if you can figure out a way to do it, I'm sure someone will come up with a use for it!

- Q: what is the refining process doing to raw materials in steel

- As Mr. Perfessor says, refining raw steel involves a lot of purifications of the raw steel; and to expand a bit, these refining processes also add corrosion-resistances to certain graded steels, and durability factors, when heat-tempering processes are used. All of these refining processes, and coating processes help steel products last when exposed to moistures, salts, and other corrosive conditions that steel can be exposed to, whether the steel is in open-air/water/space, embedded in concretes and other masonry products, or part of a protective barrier system in power plants, engines, etc. Hope this also helps; the eggster.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials as they serve as the raw material for manufacturing various types of fencing products, such as chain-link fences, barbed wires, and welded wire meshes. The steel coils are unwound and processed through different manufacturing processes, including cutting, shaping, and welding, to create the desired fencing products. The strength and durability of steel make it an ideal material for fencing, providing security and protection in various applications, such as residential, commercial, and industrial settings.

- Q: What is the standard diameter of steel coils?

- The standard diameter of steel coils can vary depending on the industry and specific application, but it is typically between 24 to 72 inches.

- Q: I really need help what is the origon of stainless steel?

- Source Of Stainless Steel

- Q: I am refinishing a table and on my can of polyurethane, it indicates not to sand with steel wool prior to application. Why is that?

- it can turn dark! use 400 to 600grit wetdry sandpaper watch your edges!!!

- Q: What are the common coil slitting equipment used in the industry?

- The common coil slitting equipment used in the industry include slitting lines, slitter knives, and tension stands. Slitting lines are machines used to cut a large coil into smaller coils of desired widths. Slitter knives are sharp blades mounted on the slitting line that perform the cutting process. Tension stands are used to control the tension of the coils during the slitting process, ensuring smooth and accurate cuts.

Send your message to us

STAINLESS STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords