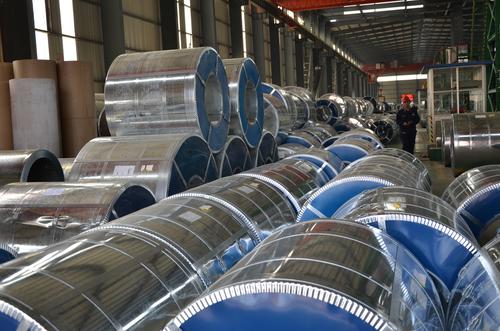

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) Quality Standard & Grade: JIS G3302, SGCC / ASTM 653M CQ/ EN10142 DX51D+Z

2) Thikness tolerance: +/-0.02mm Width tolerance:+/0.02mm

3) Zinc coating weight: 50g/m2

4) WEIGHT OF PER COIL: 3-5MT

5)Technology: cold rolled

6) Surface of Product: regular spangle / big spangle/ small spangle; Surface Treatment: chromated , non oiled, skin passed

7) Packing: export standard packing,packed with moisture resistant paper and metal

wrapping,securely tied for export,on metal skids7) Country of Origin :

SIZE:0.3*1000

- Q: How are steel coils used in the manufacturing of agricultural structures?

- Due to their durability, strength, and versatility, steel coils play a vital role in the manufacturing of agricultural structures. Typically made from high-quality steel, these coils are utilized in various ways throughout the construction process of agricultural buildings such as barns, silos, and storage facilities. One primary application of steel coils in agricultural structures is seen in the creation of the building's framework. The coils are unwound, cut into specific lengths, and then bent, shaped, and welded together to form the structural framework. The exceptional strength and rigidity of steel coils make them an ideal choice for withstanding the heavy loads and harsh environmental conditions commonly found in agricultural settings. Moreover, steel coils are also used in the production of different components and accessories for agricultural structures. These coils can be transformed into panels, roofing sheets, doors, and windows, which are essential elements in constructing agricultural buildings. The ability to customize the shape, size, and thickness of the steel coils allows for flexibility in design and ensures that the finished structure meets the specific requirements of the agricultural application. Furthermore, steel coils play a crucial role in providing protection and safety within agricultural structures. They are employed in fabricating fencing and gates, creating secure boundaries and preventing unauthorized access. Steel coils can also reinforce the walls and floors of the building, enhancing its stability and durability. Additionally, steel coils offer excellent resistance to corrosion, which is particularly important in agricultural structures due to exposure to moisture, chemicals, and other corrosive elements. Their durability ensures that the structure remains intact and functional for an extended period, thereby reducing maintenance and replacement costs. In conclusion, steel coils are indispensable in the manufacturing of agricultural structures. Their strength, durability, versatility, and resistance to corrosion make them an ideal choice for constructing the framework, components, and accessories of these buildings. By utilizing steel coils in the manufacturing process, agricultural structures can be built to withstand heavy loads, harsh environmental conditions, and provide long-lasting protection for agricultural operations.

- Q: I don't know why but I'm having a VERY difficult time finding the melting point of 1008 steel.

- It is still the same for 1008 steel. Go to the bottom and see the listing of the grades it covers. Since the only difference between the 1006 and 1008 steel is a few micro amounts of alloys and by far the greatest majority or main component is iron (99%), as a general melt temperature , 2750 F is the melt temperature at which the other alloys are added to the charge to fine tune the mix. Just like adding salt to distilled water actually lowers the boiling point of water, adding alloys to iron decreases the melting point of iron. The iron melts at 2800F, but once alloys to make the 1008 grade are added, it decreases melt temp to 2750F. Since the melting point of pure iron is 2800F, the temperature is actually decreased by adding these impurities of alloys. These alloys are tested while the mix is starting to come down from a pure melt, steel is sampled. and then alloys below are checked and added to make the 1008 steel. The steel is maintained at 2750 F so that the less volatile alloys don't boil off before combining with steel. Minimum Properties Ultimate Tensile Strength, psi 43,900 - 51,900 Yield Strength, psi 26,100 - 34,800 Elongation 42 - 48% Chemistry Iron (Fe) 99% Carbon (C) 0.08% Manganese (Mn) 0.6% max Phosphorus (P) 0.035% max Copper (Cu) 0.2% min Sulfur (S) 0.04%

- Q: How are steel coils used in the manufacturing of automotive bodies?

- Steel coils are used in the manufacturing of automotive bodies as the primary material for forming various structural components, such as body panels, frames, and reinforcements. These coils are typically fed into stamping presses, where they are shaped and cut into the desired shapes and sizes. The strength and durability of steel make it an ideal choice for automotive bodies, providing a solid foundation for safety and structural integrity.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. Steel is a highly recyclable material, and steel coils can be melted down and used to produce new steel products. Recycling steel coils not only helps to conserve resources and reduce waste but also contributes to a more sustainable and environmentally-friendly manufacturing process.

- Q: How are steel coils transported?

- Steel coils are typically transported using specialized flatbed trucks or railcars. The coils are carefully loaded onto these vehicles and secured using straps or chains to prevent any movement during transit. In some cases, shipping containers are also used to transport steel coils via cargo ships.

- Q: What are the dimensions of steel coils used in the pipeline industry?

- The dimensions of steel coils used in the pipeline industry vary depending on the specific requirements of the project. However, common dimensions for steel coils used in the pipeline industry range from 0.5 to 2 inches in thickness and 24 to 60 inches in width. The length of the coils can vary, but they are typically around 100 to 200 feet long.

- Q: What are the common coil defects and their causes?

- Common coil defects include: 1. Coil breaks: These are caused by improper handling, excessive tension, or defects in the raw material. They result in breaks or fractures in the coil. 2. Edge waves: Edge waves occur due to uneven tension during winding, improper coil alignment, or excessive elongation. This leads to wavy or uneven edges in the coil. 3. Buckling or wrinkling: Buckling or wrinkling can be caused by excessive elongation, improper winding tension, or uneven cooling. It results in irregularities or folds in the coil surface. 4. Slivers: Slivers are thin strips of material that can be present on the surface of the coil. They are typically caused by poor shearing or cutting processes, improper cleaning, or debris in the production line. 5. Oil spots: Oil spots are oily or greasy stains that can appear on the coil surface. They are usually caused by inadequate cleaning or lubrication during the manufacturing process. 6. Coating defects: Coating defects can include uneven or inconsistent coating, bubbles, or peeling. These defects can be caused by issues with the coating application process, improper drying or curing, or contamination in the coating material. It is important to address these coil defects promptly to ensure product quality and prevent further issues during subsequent processing or usage.

- Q: How do steel coils contribute to strength and durability in manufacturing?

- Strength and durability in manufacturing are enhanced by steel coils in several ways. Firstly, steel possesses inherent strength due to its high tensile strength, enabling it to bear heavy loads and resist deformation. Coiling steel involves hot rolling or cold rolling, which further enhances its strength and durability. During hot rolling, steel is heated to high temperatures and passed through rollers to shape it into a coil. This process aligns the steel's grain structure, resulting in a more uniform material with reduced internal stresses. Consequently, it becomes stronger and more resilient, maintaining its structural integrity even during manufacturing processes like bending, stamping, and forming. In contrast, cold rolling involves passing steel through rollers at room temperature. This process not only increases strength and hardness but also improves the surface finish. Cold-rolled steel coils are known for their smooth and uniform appearance, making them ideal for applications where aesthetics are crucial. Moreover, steel coils can be coated with various protective layers to enhance durability. Coatings like zinc or polymer-based ones act as barriers against corrosion, moisture, and other environmental factors that can weaken the steel. By preventing rust and degradation, these coatings prolong the lifespan of steel coils and the products they are used in, making them more durable and cost-effective in the long term. In summary, steel coils contribute to strength and durability in manufacturing by providing a resilient material capable of withstanding heavy loads and resisting deformation. The hot rolling and cold rolling processes further enhance the steel's strength and uniformity, while protective coatings prevent corrosion and extend the coils' lifespan. Ultimately, steel coils are indispensable components in manufacturing, enhancing the strength and durability of a broad range of products.

- Q: I know copper pots are supposed to be really good for cooking with, and I have been looking around online. One thing I don't want to do, however, is send them in to be re-lined with tin. So I was wondering if stainless steel lined copper pots work as well as the traditional tin lined ones, or if those make the copper just for looks.

- Stainless steel is durable and does not disolve and make things taste funny. Stainless steel is not a good conductor of heat, so it has hot and cold spots. Copper is very good conductor. They noe bond copper to stainless steel to get the best features of each. Some pots just have a very thin copper plating to fool you. A good pot will be heavier, It is really hard to tell from looking.if it is plating or a bonded layer of copper. the thicker the better

- Q: How are steel coils used in the manufacturing of power generation equipment?

- Steel coils are used in the manufacturing of power generation equipment as they are shaped and formed into various components such as turbine blades, casings, and structural supports. The strength and durability of steel make it suitable for withstanding high temperatures and pressures, ensuring the reliability and longevity of the equipment. Additionally, steel coils are often used in the production of electrical transformers and generator cores, providing a magnetic circuit that efficiently converts mechanical energy into electrical energy.

Send your message to us

galvanized steel coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords