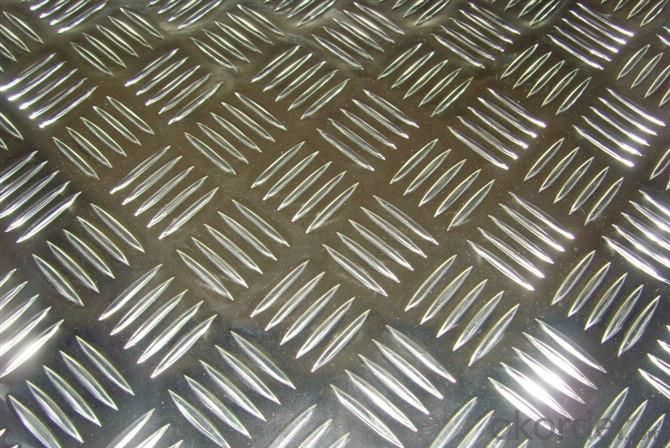

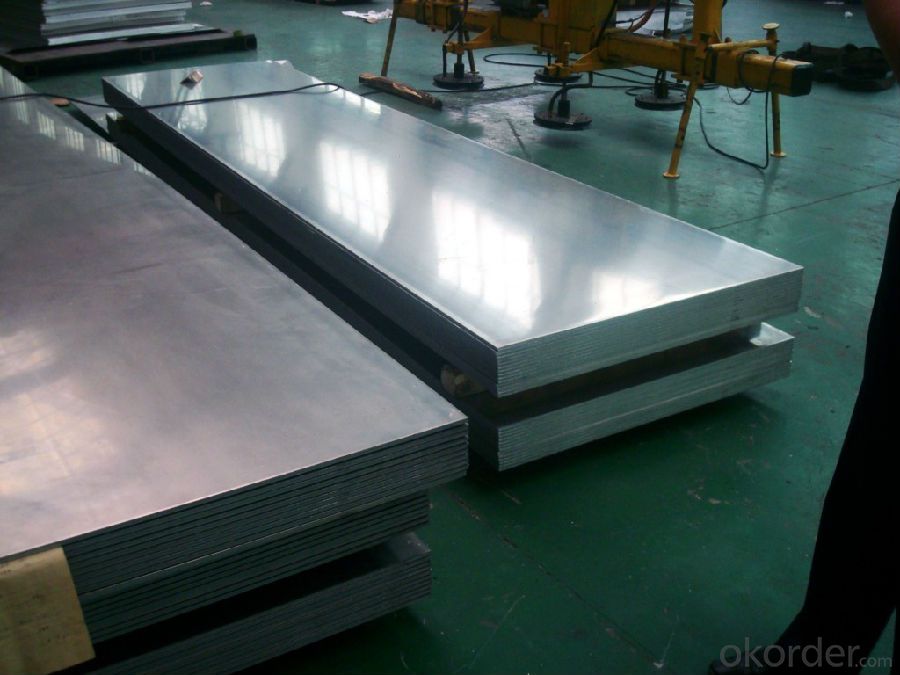

Stucco Embossed Color Coated Diamond Embossed Aluminum Sheet Coil Plate for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color Coated Diamond Embossed Aluminum Sheet Coil Plate for Roofing

Description

Aluminium Sheet | ||||||

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100,1235 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

3003,3004,3105 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

5052,5083,5754 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC | |

4.0-150 | 1000-1900 | H112, H111 | DC | |||

8011 | 0.08-0.20 | 400-1500 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |

Packing | Export standard wooden packing | |||||

Application | Mainly in Construction , decoration, PCB materials, cover material, piping, refrigeration, air conditioner, automobile, etc. | |||||

MOQ | 5MT | |||||

Kind attention | Specifications can be customized as the customer’s requirements. | |||||

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Do 101 aluminum sheets have any specific insulation properties?

- No, 101 aluminum sheets do not have any specific insulation properties. Aluminum is a good conductor of heat and electricity, which means it does not provide insulation against heat or cold. However, aluminum sheets can be used as a reflective surface to reflect heat or light. To provide insulation, additional materials such as foam or fiberglass can be added along with the aluminum sheets.

- Q: What are the different forming methods for aluminum sheets?

- There are several different forming methods that can be used to shape aluminum sheets. These methods include: 1. Roll Forming: This process involves passing the aluminum sheets through a series of rollers that gradually shape the material into the desired form. Roll forming is often used to create long, continuous shapes such as channels or rails. 2. Press Forming: Press forming uses hydraulic or mechanical presses to apply force to the aluminum sheet, creating the desired shape. This method is commonly used for forming complex shapes with tight tolerances. 3. Stretch Forming: In stretch forming, the aluminum sheet is clamped at its edges and then stretched over a die, causing the material to conform to the shape of the die. This method is often used to produce curved or contoured parts. 4. Deep Drawing: Deep drawing involves placing a blank of aluminum sheet into a die and then using a punch to force the material into the die cavity, creating a hollow shape. This method is commonly used to produce cylindrical or box-shaped parts. 5. Hydroforming: Hydroforming uses hydraulic pressure to shape the aluminum sheet against a die. This method is particularly useful for producing complex, intricate shapes with smooth surfaces. 6. Incremental Sheet Forming: In incremental sheet forming, a CNC machine moves a small tool over the surface of the aluminum sheet, gradually shaping it by applying localized pressure. This method is often used for prototyping or small-scale production. These forming methods offer different advantages and are suitable for different applications. The choice of method depends on factors such as the desired shape, complexity, and volume of production.

- Q: Aluminum and oxygen gas react to produce aluminum oxide

- Aluminium oxide is Al2O3, so there are 3 oxygen atoms for every 2 aluminium atoms. Divide 75 by the relative atomic mass of oxygen (15.9994). That is proportional to the number of oxygen atoms. Then divide by 3 and multiply by 2. This gives a number proportional to the number of aluminium atoms. Then multiply this by the relative atomic mass of aluminium (26.981529) to give the mass of aluminium required in grams.

- Q: If Aluminum can, in fact, not be sterilized I would love to know why.

- Sterilization refers to the ability to clean a surface of bacterium. Simply pouring rubbing alcohol on something sterilizes it. Aluminum can be sterilized just as good as any other metal. If it couldn't, would we ship our favorite drinks in cans of it?

- Q: Is it possible to use aluminum sheets in environments with low temperatures?

- <p>Yes, aluminum sheets can be used in cold climates. Aluminum has excellent corrosion resistance and maintains its strength in low temperatures, making it suitable for use in cold environments. It does not rust or corrode easily, which is beneficial in harsh weather conditions. However, it's important to consider thermal expansion and contraction, as aluminum expands and contracts more than some other materials. Proper installation and design considerations are necessary to account for these properties in cold climates.</p>

- Q: Can aluminum sheet be used for chemical processing?

- Yes, aluminum sheet can be used for chemical processing. Aluminum has excellent corrosion resistance and is often used in chemical processing industries for various applications such as storage tanks, reaction vessels, and heat exchangers.

- Q: Can aluminum sheets be used for electronic enclosures?

- Yes, aluminum sheets can be used for electronic enclosures. Aluminum is a lightweight and durable material that offers excellent heat dissipation properties, making it suitable for protecting electronic components. Additionally, aluminum sheets can be easily fabricated to create custom enclosures that provide electromagnetic shielding and protection against environmental factors.

- Q: To an idiot, this may seem like a stupid question: its just aluminum. But it may not be.However seeing that I am only a high school student and don't have access to aluminum power (which is what I desire for an independent experiment) so I'd like to grind consumer grade aluminum foil down bases of Mohs scale of Hardness.My concern is that aluminum foil is Aluminum oxide which is a 9 (10 being diamond, 1 being talcum powder) and this would be horribly difficult to grind.If it is Alumina, that's only a 3.5.If it does happen to be aluminum oxide, can you think of a way to remove the Oxygen. Would nitric acid work.

- It is not aluminum oxide. It's pretty much pure aluminum, though it may be coated with a very thin layer of wax or plastic. As for the independent experiment, be careful and wear goggles and other protective clothing. I was in high school once too, and can tell you from experience that thermite burns very, very hot and is quite good at melting or combusting a wide variety of materials. It also requires a fairly hot ignition source, and magnesium strips are often used for that purpose as a kind of fuse. If you don't have access to that, figure something else out, but do *not* attempt to light thermite directly with a blowtorch. You want to be much farther away by the time it lights, and it would be a bad idea to lay the torch there and back away because that places the torch's potentially explosive fuel supply much too close to the reaction.

- Q: Are aluminum sheets resistant to saltwater corrosion?

- Yes, aluminum sheets are generally resistant to saltwater corrosion. Aluminum has a natural ability to form a protective oxide layer when exposed to air or water, including saltwater. This oxide layer acts as a barrier, preventing further corrosion and protecting the underlying metal. Additionally, aluminum is lightweight and durable, making it a popular choice for various marine applications such as boats, shipbuilding, and offshore structures. However, it is important to note that the resistance to saltwater corrosion can vary depending on the specific alloy and surface treatment of the aluminum sheets. Therefore, proper selection of the appropriate alloy and protective coatings can further enhance the corrosion resistance of aluminum sheets in saltwater environments.

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- The density of aluminum is 2.7g/cm^3.

Send your message to us

Stucco Embossed Color Coated Diamond Embossed Aluminum Sheet Coil Plate for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords