Aluminum Coil Weight Per Square Foot - Aluminum Coil Sheets PVDF and PE Color Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Coil Sheets PVDF and PE Color Coated

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Aluminum Coil Sheets PVDF and PE Color Coated

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum Coil Sheets PVDF and PE Color Coated

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

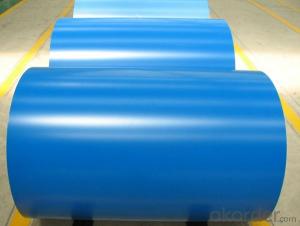

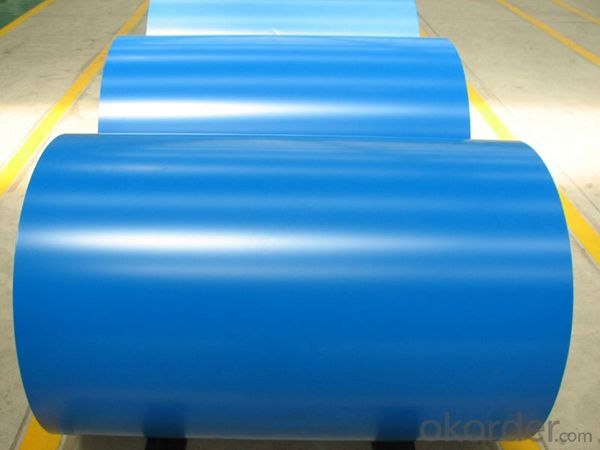

5. Image of Aluminum Coil Sheets PVDF and PE Color Coated

6. Package and shipping of Aluminum Coil Sheets PVDF and PE Color Coated

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils used in the production of medical equipment?

- Aluminum coils are widely used in the production of medical equipment due to their unique properties and versatility. One of the primary applications of aluminum coils in the medical industry is in the manufacturing of various medical devices, such as MRI machines, X-ray machines, and ultrasound equipment. Aluminum coils are utilized in the production of medical equipment mainly because of their excellent conductivity. This property allows them to efficiently conduct and dissipate heat, which is crucial for the proper functioning of medical devices. For instance, MRI machines generate a significant amount of heat during operation, and aluminum coils help in regulating and maintaining the desired temperature to ensure optimal performance and patient safety. Moreover, aluminum coils are also highly malleable and can be easily formed into different shapes and sizes. This makes them ideal for the production of medical equipment, where intricate designs and precise specifications are often required. For example, aluminum coils are used in the construction of radiation shields, which protect medical personnel and patients from harmful radiation emitted by X-ray machines. In addition, aluminum coils are lightweight yet durable, making them an excellent choice for medical equipment that needs to be portable or easily maneuvered. This is particularly important for devices like portable ultrasound machines, where lightweight components are necessary for ease of use and transportation. Furthermore, aluminum coils have excellent corrosion resistance, which is vital in the medical field where cleanliness and hygiene are of utmost importance. The resistance to corrosion helps in preventing the buildup of bacteria, germs, and other contaminants on the surface of medical equipment, ensuring a safe and sterile environment for patients and healthcare professionals. Overall, aluminum coils play a crucial role in the production of medical equipment by providing properties such as conductivity, malleability, lightweight, durability, and corrosion resistance. These properties allow for the efficient and safe operation of medical devices, contributing to improved patient care and well-being.

- Q: Explain how aluminum coils function to shield against electromagnetic interference.

- <p>Aluminum coils protect against electromagnetic interference (EMI) through a process known as electromagnetic shielding. Aluminum, being a conductive material, can reflect and absorb EMI, preventing it from penetrating the protected area. When an aluminum coil is used as a shield, it creates an electric field that interacts with the EMI, either reflecting the interference back or absorbing it, thus reducing its impact on sensitive electronic equipment. The high conductivity of aluminum also allows it to distribute the EMI evenly across its surface, minimizing the effect of any single point of entry. This shielding is crucial in various applications, such as in electronic devices and communication systems, to ensure reliable performance and data integrity.</p>

- Q: How are aluminum coils joined in a continuous process?

- Aluminum coils are joined in a continuous process using various techniques such as welding, brazing, and adhesive bonding. Welding is a common method used to join aluminum coils together. It involves melting the edges of the coils and then fusing them together. This can be achieved through various welding processes such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or laser welding. These methods provide a strong and durable bond between the coils. Brazing is another technique used for joining aluminum coils. It involves heating the coils and using a filler material with a lower melting point than the aluminum to create the joint. The filler material, often a brazing alloy, is applied to the joint area, and when heated, it melts and flows into the gap between the coils, forming a solid bond upon cooling. Adhesive bonding is also employed in the continuous joining of aluminum coils. This method involves applying a specialized adhesive or glue to the surfaces of the coils that need to be joined. The adhesive is carefully selected to have excellent bonding properties with aluminum. The coils are then pressed together, and the adhesive cures, creating a strong and reliable bond. Each joining technique has its advantages and is chosen based on factors such as the application requirements, the type of aluminum being used, and the desired level of strength and durability. The choice of joining method in a continuous process depends on the specific needs of the production line and the final product.

- Q: im taking avelox antibiotic for my thorat bacterial infection....i brought guava juice today but i think it contains magnesium or aluminum....how long after taking avelox can i drink the guava juice????

- call a pharmacist

- Q: Can aluminum coils be used in corrosive gas environments?

- Yes, aluminum coils can be used in corrosive gas environments. Aluminum has a natural oxide layer that provides excellent corrosion resistance, making it suitable for various corrosive environments including those with corrosive gases. However, it is important to consider the specific corrosive gas and its concentration, as certain gases may still have a corrosive effect on aluminum over time.

- Q: Are aluminum coils resistant to chemicals?

- Yes, aluminum coils are generally resistant to chemicals. Aluminum has excellent corrosion resistance and can withstand exposure to various chemicals, making it a suitable choice for applications that involve chemical processing or storage.

- Q: How are aluminum coils used in the manufacturing of cookware?

- Aluminum coils are widely used in the manufacturing of cookware due to their excellent heat conductivity and lightweight nature. Cookware manufacturers typically use aluminum coils as the primary material for constructing the bases and bodies of pots, pans, and other cooking utensils. Firstly, aluminum coils are rolled out and then cut into different shapes and sizes depending on the desired cookware product. These coils are preferred over other materials, such as stainless steel or cast iron, because aluminum conducts heat more efficiently. This allows for even distribution of heat across the surface of the cookware, ensuring that food cooks evenly and thoroughly. Additionally, aluminum coils are lightweight, making the resulting cookware easier to handle and maneuver. This is particularly beneficial for professional chefs and home cooks who often need to lift and move pots and pans during the cooking process. Moreover, aluminum is a malleable material, meaning it can be easily shaped and formed into various cookware designs and styles. Whether it's a saucepan, frying pan, or baking tray, aluminum coils can be molded to create the desired shape and size, allowing for versatility in cookware manufacturing. Furthermore, aluminum has a natural resistance to corrosion, making it a durable choice for cookware. It does not react with acidic or alkaline ingredients commonly used in cooking, ensuring that the cookware remains safe for food preparation and cooking. Lastly, aluminum coils can be treated with non-stick coatings, such as Teflon, to create non-stick cookware. These coatings provide an additional layer of convenience, allowing for easy food release and hassle-free cleaning. In summary, aluminum coils play a crucial role in the manufacturing of cookware by providing excellent heat conductivity, lightweight construction, versatility in design, durability, and the option for non-stick coatings. These qualities make aluminum coils an ideal choice for producing high-quality cookware that delivers superior cooking performance and convenience in the kitchen.

- Q: Almost every restaraunt uses aluminium foils and polyehylene for packing foods - that you carry to home.How safe is this ?For how long would the temperature be mainitained ?and within what time if consumed and is it safe ?

- Aluminium (Al) foil is bad for packaging because some of the Al will be absorbed by the food and too much Al is toxic. Instead of Al cooking vessels you should use stainless steel vessels because some Al will end up in your food from the Al containers or vessels. If you conduct a search for Aluminium (OR Al) poisoning you should learn more. A search for aluminium (OR Al) + toxic dose (OR amount) may also be useful.

- Q: Are aluminum coils suitable for roofing?

- Yes, aluminum coils are indeed suitable for roofing. Aluminum is a highly durable and lightweight material that has been widely used in the construction industry for roofing purposes. It offers numerous benefits such as being resistant to rust, corrosion, and fire, making it an ideal choice for areas with harsh weather conditions or high humidity. Aluminum coils are also known for their excellent thermal conductivity, which helps in reflecting sunlight and reducing energy consumption, leading to lower cooling costs. Additionally, aluminum roofing is easy to install and maintain, providing long-lasting protection for residential, commercial, and industrial buildings.

- Q: How are aluminum coils protected from corrosion?

- Various methods and coatings can be utilized to safeguard aluminum coils from corrosion. One prevalent technique involves anodizing, where the coils are immersed in an electrolyte solution and subjected to an electric current. This process generates a thick oxide layer on the aluminum surface, providing exceptional resistance against corrosion. Another approach entails applying a protective coating to the aluminum coils. These coatings, which can be organic or inorganic (such as polyester, epoxy, or polyvinylidene fluoride), act as a barrier, effectively preventing moisture and corrosive substances from reaching the surface. Additionally, the use of sacrificial coatings can be employed for aluminum coil protection. This technique involves applying a layer of a more reactive metal, like zinc or magnesium, onto the aluminum surface. By sacrificing itself, this coating corrodes instead of the aluminum, effectively shielding it from corrosive elements. To prevent corrosion, regular cleaning and maintenance are crucial. It is imperative to routinely eliminate accumulated dirt, debris, and corrosive substances from the coil's surface in order to maintain its corrosion resistance. By combining anodizing, protective coatings, sacrificial coatings, and proper maintenance, the longevity and performance of aluminum coils are effectively preserved, ensuring their optimal protection against corrosion.

Send your message to us

Aluminum Coil Weight Per Square Foot - Aluminum Coil Sheets PVDF and PE Color Coated

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords