3003 Coated Aluminum Coil for Color Coating Window Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

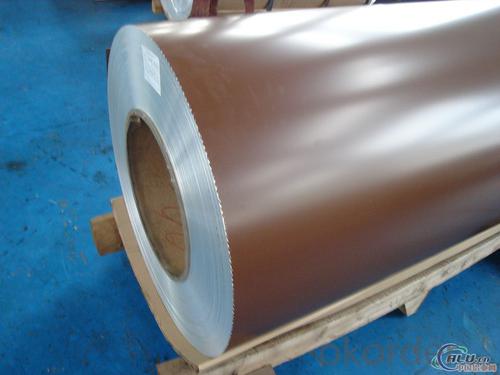

1.Structure of Aluminum Coil for Color Coating Window Panel

Aluminum Coil for Color Coating Window Panel is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Aluminum Coil for Color Coating Window Panel

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image of Aluminum Coil for Color Coating Window Panel

4. Product Specification

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA1050 | H18 | 0.2MM-3MM | 1200MM-1500MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Are aluminum coils resistant to abrasion?

- Yes, aluminum coils are generally resistant to abrasion. Aluminum is known for its durability and ability to withstand wear and tear. It has a high strength-to-weight ratio and excellent corrosion resistance properties, making it suitable for various applications where abrasion resistance is required. Additionally, aluminum coils are often coated or treated with protective finishes, further enhancing their resistance to abrasion. However, the specific level of resistance may vary depending on the specific alloy and the surface treatment applied to the coils.

- Q: Can aluminum coils be used for electrical transformers?

- Indeed, electrical transformers can utilize aluminum coils. The application of aluminum as a material for transformer coils is attributed to its superior electrical conductivity and cost-effectiveness in comparison to copper. Traditionally, copper has been favored for transformer windings; nevertheless, the utilization of aluminum has gained traction in recent times due to its lighter weight and more affordable price. Additionally, aluminum coils offer advantages in terms of thermal conductivity, as they efficiently dissipate heat in contrast to copper. Nevertheless, it is crucial to take into account the specific demands and design considerations of the transformer, as the decision between aluminum and copper coils may hinge upon factors such as voltage, current, size, and insulation requirements.

- Q: Are there any specific guidelines for the storage of aluminum coils?

- Yes, there are specific guidelines for the storage of aluminum coils. Aluminum coils should be stored in a dry, well-ventilated area to prevent moisture buildup and corrosion. They should be stacked horizontally on a level surface, with proper support to avoid deformation. Additionally, it is recommended to cover the coils with a protective material, such as plastic or cloth, to prevent dust, dirt, or other contaminants from accumulating on the surface.

- Q: What are the common surface treatments applied to aluminum coils?

- There are several common surface treatments that are applied to aluminum coils to enhance their durability, appearance, and resistance to corrosion. One of the most common treatments is anodizing, which involves creating a layer of oxide on the surface of the aluminum through an electrochemical process. This not only adds a protective barrier against corrosion but also allows for the application of various colors and finishes. Another common surface treatment is painting or coating. Aluminum coils can be painted with a wide range of colors and coatings to provide additional protection against corrosion, as well as to improve their aesthetic appeal. These coatings can be applied through various methods, such as powder coating or liquid spray, and can offer different levels of durability and resistance to environmental factors. Additionally, aluminum coils can undergo a process called laminating, in which a protective film or layer is applied to the surface. This film can provide added resistance to scratches, abrasions, and UV rays, making the coated aluminum coil suitable for outdoor applications. Furthermore, embossing or texturing is another surface treatment commonly used on aluminum coils. This process involves creating patterns, designs, or textures on the surface of the aluminum, which not only enhances its visual appeal but also provides additional structural strength and grip. Overall, the choice of surface treatment for aluminum coils depends on the specific requirements of the application, including the desired appearance, durability, and environmental factors. It is important to consider factors such as corrosion resistance, weatherability, and aesthetics when selecting the appropriate surface treatment for aluminum coils.

- Q: How do I write ionic formula for Sodium Aluminum Silicate? Please explain in a easy way ,,,,,,,,,,,,

- www.okorder /

- Q: Can aluminum coils be used in solar thermal systems?

- Yes, aluminum coils can be used in solar thermal systems. Aluminum is a common material used in heat exchangers due to its excellent thermal conductivity. In a solar thermal system, aluminum coils can be used as part of the heat exchanger to transfer the captured solar energy to the working fluid. The aluminum coils allow for efficient heat transfer, ensuring that the captured solar energy is effectively utilized in heating water or other fluids. Additionally, aluminum is lightweight and corrosion-resistant, making it a suitable material for outdoor applications such as solar thermal systems.

- Q: How do aluminum coils compare to iron coils in terms of weight?

- In terms of weight, aluminum coils possess a significant advantage over iron coils due to their lower density. This results in aluminum coils weighing less for the same volume. With aluminum weighing approximately one-third of iron, it becomes a substantially lighter material when utilized in coil applications. This advantage in weight proves particularly advantageous in industries prioritizing weight reduction, such as automotive and aerospace, as it enhances fuel efficiency and overall performance.

- Q: How are aluminum coils processed for further fabrication?

- Various products can be created from aluminum coils by undergoing a series of steps for further fabrication. To begin, the coil is typically uncoiled to separate it into individual sheets or strips, which can be done manually or through automation. Next, the coils are cleaned to eliminate dirt, oil, or other contaminants. This step is crucial to ensure proper adhesion and surface finish in subsequent fabrication processes. The cleaning process may involve chemical treatments, rinsing, or mechanical brushing. Following the cleaning process, the coils often go through a pre-treatment stage, such as chemical conversion coating or anodizing. These treatments enhance the surface properties of the aluminum, providing improved corrosion resistance, better adhesion for coatings, and enhanced paint adhesion. Once the pre-treatment is finished, the coils are prepared for fabrication. This can be accomplished through various techniques, such as cutting, bending, stamping, or roll forming. Cutting can be performed using shearing, sawing, or laser cutting techniques, depending on the desired dimensions and accuracy. Bending and forming are commonly utilized to shape the aluminum coils into desired profiles or structures. This can be achieved through the use of press brakes, roll forming machines, or specialized bending equipment. Stamping is another popular method of fabrication, where the coils are pressed into specific shapes using dies and punches. This technique is commonly employed in the production of automotive parts, household appliances, and electronics. Upon completion of the desired fabrication, the coils may undergo additional surface treatments or coatings to provide protection or enhance their appearance. This can include painting, powder coating, or the application of protective films. In conclusion, aluminum coils undergo a series of steps including uncoiling, surface cleaning, pre-treatment, cutting, bending, stamping, and surface treatments to facilitate further fabrication. These processes enable the transformation of the coils into various products with the desired properties and characteristics.

- Q: Can aluminum coils be used in the manufacturing of cans?

- Yes, aluminum coils can be used in the manufacturing of cans. Aluminum coils are commonly used in the canning industry as they are lightweight, durable, and provide excellent sealability, ensuring the freshness and preservation of the contents.

- Q: Can aluminum coils be used in high-temperature applications?

- Indeed, high-temperature applications can make use of aluminum coils. With its melting point reaching 660 degrees Celsius (1220 degrees Fahrenheit), aluminum proves itself as a fitting option for diverse high-temperature settings. Furthermore, its remarkable thermal conductivity enables efficient heat transfer, rendering it a favored selection for heat exchangers and HVAC systems. Nevertheless, it is crucial to acknowledge that the particular application and temperature needs must be taken into account, as exceedingly high temperatures surpassing aluminum's melting point might necessitate alternative materials.

Send your message to us

3003 Coated Aluminum Coil for Color Coating Window Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords