hot rolled steel strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Spring Steel:

Spring steel is divided into two types, one is alloy spring steel, and other one is carbon spring steel.

Alloy spring steel is a type that is used for manufacturing springs and other elastic parts. Spring steel should have high ratio of yield strength and tensile strength and elastic limit to make sure that the springs obtain enough power of elastic deformation and can bear much load.

Types of alloy spring steel: Si-Mn spring steel, Si-Cr spring steel, Cr-Mn Spring steel, Cr-V spring steel and so on.

Specification of Spring Strip Steel:

-Material: 30W4Cr2VA

-Standard: GB/T 1222-2007

-Type: Spring Steel

Chemical Composition:

C | Si | Mn | S |

0.26~0.34 | 0.17~0.37 | ≤0.40 | ≤0.030 |

P | Cr | Ni | Cu |

≤0.030 | 2.00~2.50 | ≤0.35 | ≤0.25 |

V | W | | |

0.50~0.80 | 4.00~4.50 | | |

Mechanical Properties:

-Yield Strength σs (MPa): ≥1470 (150)

-Elongation δ10(%):≥7

-Hardness:

1, Hot rolled + Heat treatment, ≤321HB

2, Cold drawn + Heat treatment: ≤321HB

-Impact Power: ≥40

Norm of heat treatment:

1, Quenching: 1050℃~1100℃.

2, Cooled by oil.

3, Tempering: 600℃±50℃.

Usage/Applications of Spring Strip Steel:

-Due to the elements W, Cr and V, this type of spring steel obtain pretty high hardenability and nice mechanical properties under room temperature and high temperature. The tempering stability and hot workability are good.

-Being used under the state of quenching and high temperature tempering. It’s usually used as heat-resisting springs with working temperature below 500℃, like main secure valve spring of furnace and turbine steam seal leaf springs.

Packaging & Delivery of Spring Strip Steel:

-Packing Detail: The products will be well packed.

-Marks: there are two types of marks.

1, Tag marks. To show customers the specifications of products, company name and logo and other information required by customers.

2, Color marks. It’s easy for customers to distinguish them from other products at destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

Payment:

-Theoretical weight/Actual weight.

-FOB, CFR or CIF.

-Terms of payment: T.T. or L/C at sight.

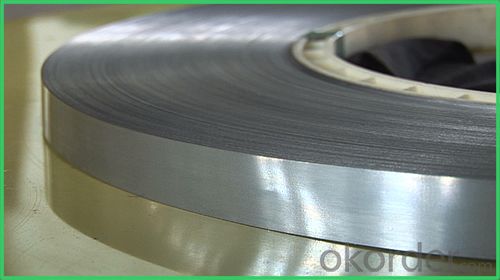

Photos of Spring Strip Steel:

- Q: Can steel strips be used in the production of surgical implants?

- Yes, steel strips can be used in the production of surgical implants. Steel is a widely used material in the medical field due to its strength, durability, and biocompatibility. Surgical implants, such as orthopedic plates, screws, and pins, often require materials with these characteristics to ensure stability and long-term performance within the human body. Steel strips can be machined, shaped, and sterilized to meet the specific requirements of surgical implants. Additionally, steel has the advantage of being corrosion-resistant, which is crucial in preventing complications or reactions in the patient's body. However, it is important to note that the type of steel used for surgical implants must comply with rigorous standards and regulations, such as ISO 5832, to ensure its biocompatibility and safety for medical applications.

- Q: Can steel strips be used in the production of kitchen appliances?

- Yes, steel strips can be used in the production of kitchen appliances. Steel is a commonly used material in the manufacturing of kitchen appliances due to its durability, strength, and resistance to corrosion. Steel strips can be used for various components and parts of kitchen appliances such as the body, frame, shelves, handles, or even internal mechanisms. The use of steel strips in kitchen appliances ensures longevity, stability, and a sleek appearance. Additionally, steel is easy to clean and maintain, making it a practical choice for kitchen appliances that are exposed to heat, moisture, and frequent use.

- Q: What are the different sizes and dimensions of steel strips?

- Steel strips come in a variety of sizes and dimensions depending on their intended use and application. The thickness of steel strips typically ranges from 0.1 mm to 6 mm, with variations available within this range. The width of steel strips can vary from 10 mm to 1500 mm, again with options within this range. Lengths of steel strips can vary depending on production requirements, but they are often available in standard coil lengths of up to 30 meters or more. The dimensions and sizes of steel strips are determined by factors such as the industry they are used in, the specific application or manufacturing process, and customer requirements. It is important to consult with steel suppliers or manufacturers to determine the exact sizes and dimensions available for a particular steel strip.

- Q: How do steel strips perform in electrical circuits?

- Steel strips do not perform well in electrical circuits as they have high resistance, which leads to significant energy losses and poor conductivity.

- Q: What are the different sizes and dimensions of steel strips?

- Steel strips come in a variety of sizes and dimensions depending on their intended use and application. The thickness of steel strips typically ranges from 0.1 mm to 6 mm, with variations available within this range. The width of steel strips can vary from 10 mm to 1500 mm, again with options within this range. Lengths of steel strips can vary depending on production requirements, but they are often available in standard coil lengths of up to 30 meters or more. The dimensions and sizes of steel strips are determined by factors such as the industry they are used in, the specific application or manufacturing process, and customer requirements. It is important to consult with steel suppliers or manufacturers to determine the exact sizes and dimensions available for a particular steel strip.

- Q: How are steel strips used in the production of medical implants?

- Steel strips are commonly used in the production of medical implants as they provide durability and strength to the final product. These strips are shaped, machined, or welded to create various components of the implant, such as screws, plates, and rods. The steel strips undergo stringent quality control measures to ensure their biocompatibility and resistance to corrosion, making them ideal for long-term implantation in the human body.

- Q: What are the specifications for steel strips used in the production of wire ropes?

- The specifications for steel strips used in the production of wire ropes can vary depending on the specific application and requirements. However, there are some general specifications that are commonly followed in the industry. 1. Material: The steel strips used in wire rope production are typically made from high-quality carbon or alloy steel. These steels have excellent strength, ductility, and fatigue resistance characteristics. 2. Size and Dimensions: The dimensions of the steel strips may vary based on the desired wire rope size and construction. Common thicknesses range from 0.15 mm to 6 mm, while widths can range from 2 mm to 100 mm. 3. Surface Finish: The steel strips used in wire rope production should have a smooth and clean surface finish to ensure proper adhesion of lubricants and coatings. The surface should be free from defects, such as cracks, scratches, or rust. 4. Mechanical Properties: The steel strips should possess specific mechanical properties to ensure the wire rope's strength and durability. These properties include a high tensile strength, good elongation, and excellent fatigue resistance. The mechanical properties are usually specified by the manufacturer according to the wire rope's intended use. 5. Coating and Protection: To enhance corrosion resistance, steel strips used in wire rope production may be coated with zinc, galvanized, or treated with other corrosion-resistant coatings. The coating thickness and type may vary depending on the application and environmental conditions. 6. Certification and Compliance: The steel strips should meet certain industry standards and certifications, such as ASTM or ISO, to ensure they meet specific quality and performance criteria. Compliance with these standards provides assurance of the strip's suitability for wire rope production. It is important to note that these specifications can vary depending on the specific requirements of the wire rope applications, such as load capacity, working environment, and safety regulations. Therefore, it is essential to consult the relevant industry standards and the wire rope manufacturer's guidelines for specific specifications and recommendations.

- Q: How do steel strips compare to other materials like aluminum or copper?

- Steel strips have several advantages over materials like aluminum or copper. Firstly, steel is stronger and more durable, making it more suitable for applications that require high strength and resistance to wear and tear. Secondly, steel is more cost-effective compared to aluminum or copper, making it a preferred choice for many industries. Additionally, steel has better thermal conductivity and is more resistant to corrosion, making it a versatile material that can be used in various environments. However, aluminum and copper may have their own advantages such as being lighter in weight or having better electrical conductivity, depending on the specific application.

- Q: How is the hardness of steel strips measured?

- The hardness of steel strips is typically measured using various methods such as the Rockwell hardness test, the Brinell hardness test, or the Vickers hardness test. Each of these methods involves applying a specific amount of force onto the steel strip's surface using a standardized indenter, and then measuring the depth or size of the resulting indentation. The hardness value is determined by comparing the indentation size or depth with a standard scale, which correlates the indentation dimensions to the material's hardness. These tests provide a quantitative measurement of the steel strip's hardness, which is crucial for assessing its mechanical properties and suitability for specific applications.

- Q: What are the different methods for bending steel strips?

- There are several methods for bending steel strips, each with its own advantages and applications. Some of the most common methods include: 1. Press brake bending: This method involves using a press brake machine, which applies force to bend the steel strip into the desired shape. The strip is placed between a punch and a die, and the machine applies pressure to create the bend. Press brake bending is commonly used for precision bending and creating complex shapes. 2. Roll bending: In this method, the steel strip is passed through a series of rollers that gradually apply pressure to bend the strip. This technique is typically used for large-scale, continuous bending operations and is suitable for creating long, curved shapes. 3. Induction bending: This method involves using an induction heating system to heat the steel strip to a malleable temperature. Once heated, the strip is bent using a bending machine or a specially designed mandrel. Induction bending allows for precise control over the bending process and is commonly used for creating smooth and consistent bends in large steel strips. 4. Rotary-draw bending: This method utilizes a bending machine equipped with a rotating die, which grips the steel strip and pulls it around a bend form. Rotary-draw bending is often used for producing tight, precise bends in small to medium-sized steel strips. 5. Mandrel bending: Mandrel bending involves inserting a mandrel, typically a solid rod or flexible coil, into the steel strip before bending. The mandrel provides support to the inner surface of the strip, preventing it from collapsing or deforming during the bending process. This method allows for the creation of smooth, wrinkle-free bends and is commonly used in applications where a high-quality finish is required. 6. Hammer bending: This traditional method involves using a hammer or mallet to manually shape the steel strip by striking it against a form or mold. Although it is a labor-intensive process, hammer bending is often used for small-scale or custom bending applications. Each method has its own advantages and limitations, and the choice of bending method will depend on factors such as the desired shape, material properties, production volume, and budget.

Send your message to us

hot rolled steel strip

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords