Cold rolled steel sheet prices of construction material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

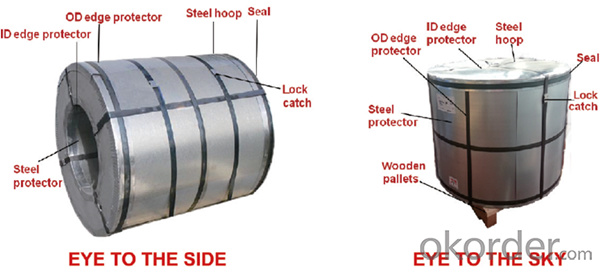

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Can steel sheets be used in the manufacturing of furniture?

- Yes, steel sheets can be used in the manufacturing of furniture. Steel is a durable and versatile material that can be shaped and formed into various furniture components like frames, legs, and surfaces. Additionally, steel sheets provide strength and stability to furniture pieces, making them suitable for both indoor and outdoor use.

- Q: Can steel sheets be bent or shaped?

- Yes, steel sheets can be bent or shaped using various techniques such as cold forming, hot forming, or using mechanical tools like press brakes or rollers.

- Q: Are steel sheets suitable for fire-resistant applications?

- Steel sheets are indeed appropriate for applications that require resistance to fire. Steel has gained a reputation for its exceptional fire resistance properties, primarily because of its high melting point and its reluctance to ignite or facilitate the spread of fire. Steel sheets can be employed in an array of fire-resistant applications, including fire doors, fire-rated walls, and fireproof enclosures. Moreover, steel sheets can be combined with other fire-resistant materials, like fire-resistant coatings or insulation, to augment their fire resistance even further. In general, steel sheets are a dependable option for fire-resistant applications owing to their robustness, potency, and capacity to endure high temperatures.

- Q: What are the different types of steel sheet finishes for automotive applications?

- Automotive applications commonly utilize various types of steel sheet finishes. These finishes are applied to the surface of the steel sheet for the purpose of enhancing its appearance, durability, and resistance to corrosion. The mill finish, for instance, is a natural finish that the steel sheet attains after undergoing hot or cold rolling. It possesses a dull gray appearance and is typically employed in applications where aesthetics are not of paramount importance. On the other hand, the galvanized finish is a favored choice, whereby a layer of zinc is coated onto the steel sheet to safeguard it against corrosion. This finish exhibits exceptional resistance to corrosion and is frequently utilized in automotive body panels and structural components. Another option is the painted finish, which involves coating the steel sheet with a layer of paint. This finish improves both the aesthetics and corrosion protection of the steel sheet. Painted finishes are available in a variety of colors and textures, offering customization and branding possibilities. Furthermore, specialized finishes, such as the electro-galvanized finish, are also available. This finish involves the application of a thin layer of zinc to the steel sheet through an electroplating process. It provides enhanced corrosion resistance and is commonly employed in automotive parts that necessitate a high level of rust protection. Lastly, the brushed or polished finish entails mechanical polishing of the steel sheet surface to create a smooth and reflective appearance. This finish is often used for decorative purposes in automotive applications, like trim or accents. In conclusion, the range of steel sheet finishes for automotive applications includes mill finish, galvanized finish, painted finish, electro-galvanized finish, and brushed/polished finish. Each finish offers distinct advantages in terms of appearance, durability, and corrosion resistance, enabling manufacturers to select the most suitable option for their specific automotive application.

- Q: Can steel sheets be used for railway applications?

- Yes, steel sheets can be used for railway applications. Steel sheets are commonly used in the construction of railway tracks, bridges, and other infrastructure due to their high strength, durability, and resistance to wear and tear. They can be formed into various shapes and sizes to meet the specific requirements of railway applications. Additionally, steel sheets can be easily welded, which allows for efficient and cost-effective installation and repair of railway components. Overall, steel sheets are a popular choice in the railway industry due to their excellent mechanical properties and ability to withstand heavy loads and harsh environmental conditions.

- Q: What material is steel plate against drilling?

- There is also an ordinary steel sheet drilling method: steel plate carburizing, quenching treatment, to achieve high hardness.

- Q: Can steel sheets be used in electrical applications?

- Yes, steel sheets can be used in electrical applications. They are commonly utilized in the construction of enclosures, cabinets, and panels for electrical equipment due to their durability, strength, and ability to provide electromagnetic shielding.

- Q: Can the steel sheets withstand extreme temperatures?

- Yes, steel sheets are designed to withstand extreme temperatures and maintain their structural integrity.

- Q: Are the steel sheets available in different thickness tolerances?

- Certainly, there are various thickness tolerances for steel sheets that are readily available. Steel producers create sheets with diverse thicknesses to accommodate different purposes and demands. These tolerances are determined by established standards within the industry and can differ based on the steel type and intended application. In construction, for instance, tighter tolerances might be mandatory to guarantee the structural soundness, while in manufacturing sectors like automotive or aerospace, precise tolerances may be indispensable to meet design requirements. Through offering steel sheets in varying thickness tolerances, manufacturers allow customers to select the most fitting product for their individual requirements.

- Q: Can steel sheets be formed into corrugated panels?

- Yes, steel sheets can be formed into corrugated panels.

Send your message to us

Cold rolled steel sheet prices of construction material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 59450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords