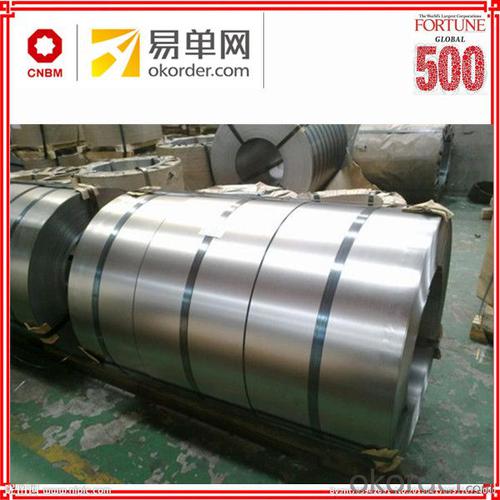

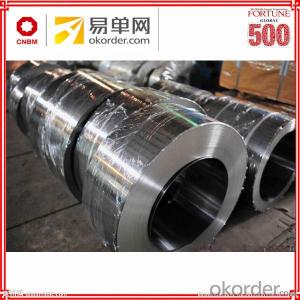

Cold rolled steel sheet hot sale in alibaba china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

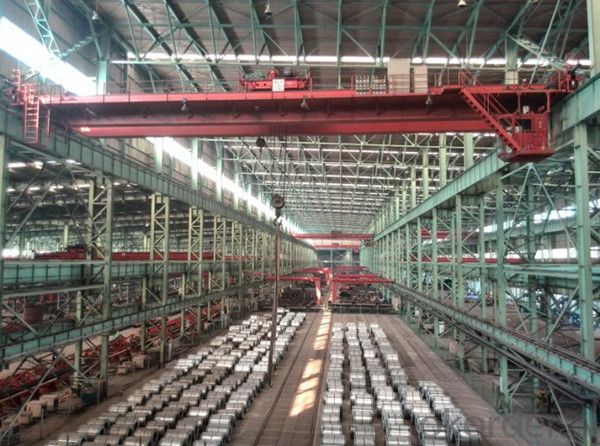

- Supply Capability:

- 61450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

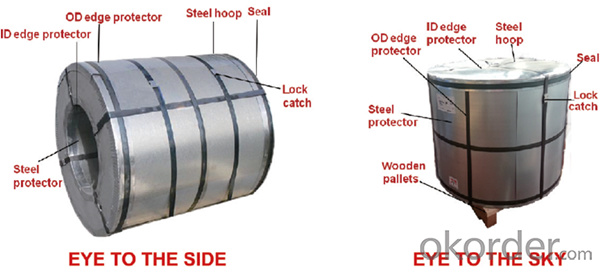

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What is the difference between a smooth and perforated stainless steel sheet?

- A smooth stainless steel sheet has a flat, even surface, while a perforated stainless steel sheet has small holes or perforations evenly distributed across its surface. These holes serve various purposes such as allowing for the passage of air or fluids, enhancing sound absorption, or providing a decorative element.

- Q: What are the advantages of using galvanized steel sheets?

- Using galvanized steel sheets in various applications offers several advantages. Firstly, they exhibit high resistance to corrosion. The process of galvanizing involves applying a zinc layer to the steel sheets, which acts as a protective barrier against rust and other forms of corrosion. This makes galvanized steel sheets ideal for outdoor applications or environments that are prone to moisture, like construction sites or coastal areas. Secondly, galvanized steel sheets possess excellent durability and longevity. The zinc coating enhances their overall strength and resistance to wear and tear. Consequently, galvanized steel sheets can withstand heavy loads, extreme temperatures, and other harsh conditions, making them suitable for long-term use. Moreover, galvanized steel sheets prove to be cost-effective. Though the initial cost may be slightly higher compared to other materials, their long lifespan and low maintenance requirements offset this investment. Galvanized steel sheets do not require frequent painting or sealing, saving both time and money in the long run. Furthermore, galvanized steel sheets are environmentally friendly. The zinc coating used in the galvanizing process is recyclable, contributing to sustainable practices. Additionally, the extended lifespan of galvanized steel sheets reduces the need for frequent replacements, minimizing waste and conserving resources. Lastly, galvanized steel sheets offer versatility in terms of applications. They can be easily formed, shaped, and cut to meet specific requirements, making them suitable for a wide range of industries, including construction, automotive, and manufacturing. The ability to customize galvanized steel sheets ensures their compatibility with various designs and structural needs. In conclusion, the benefits of using galvanized steel sheets encompass superior corrosion resistance, durability, cost-effectiveness, environmental friendliness, and versatility. These advantages make galvanized steel sheets a favored choice across numerous industries and applications.

- Q: What is the average price of steel sheets?

- The average price of steel sheets can vary depending on factors such as size, thickness, and market conditions. It is recommended to check with steel suppliers or refer to industry reports for the most up-to-date and accurate pricing information.

- Q: Can steel sheets be used for automotive wheels?

- Yes, steel sheets can be used for automotive wheels. Steel wheels are commonly used in vehicles due to their durability and cost-effectiveness. However, it is important to note that steel wheels are typically heavier than other materials such as aluminum alloy, which may impact the vehicle's performance and fuel efficiency.

- Q: How do steel sheets perform in terms of dimensional stability?

- Steel sheets have excellent dimensional stability. This is because steel is a strong and rigid material that resists warping, bending, and expanding or contracting due to temperature changes. It maintains its shape and size, making it an ideal choice for applications that require precise and consistent dimensions.

- Q: What's the difference between single rolling steel sheet and continuous rolling steel plate?

- Single rolled steel plate usually refers to medium plate, in the process of rolling and finishing, the plate has been flat, usually thicker (6mm or more), the width of the fastest up to 4800mm.

- Q: What is the typical thickness tolerance for steel sheets?

- The typical thickness tolerance for steel sheets can vary depending on the specific industry and application requirements. However, in general, the standard thickness tolerance for steel sheets is typically around ±0.005 to ±0.010 inches (0.13 to 0.25 mm). This means that the actual thickness of the steel sheet can deviate within this range from the specified nominal thickness. It is important to note that certain industries or applications may have more stringent tolerance requirements, especially when precision is critical. In such cases, the tolerance may be tighter, ranging from ±0.001 to ±0.003 inches (0.025 to 0.076 mm). Additionally, specialized steel products or specific customer requirements may also result in different tolerance specifications. To ensure compliance with the desired thickness tolerance, manufacturers employ strict quality control measures such as precise calibration of equipment, regular inspection of raw materials, and comprehensive testing procedures. This helps to maintain the integrity and reliability of steel sheets for various applications in industries such as automotive, construction, manufacturing, and more.

- Q: Are steel sheets suitable for railway applications?

- Yes, steel sheets are suitable for railway applications. They are commonly used in the construction of railway tracks, bridges, and rolling stock due to their durability, strength, and ability to withstand heavy loads and harsh weather conditions. Steel sheets also provide excellent resistance to wear, corrosion, and fatigue, making them a reliable choice for railway infrastructure.

- Q: Can steel sheets be used for soundproofing?

- Yes, steel sheets can be used for soundproofing to some extent. While steel itself is not an ideal soundproofing material due to its density and ability to conduct sound, it can still provide some level of noise reduction when used in combination with other soundproofing materials like insulation or acoustic foam. The thickness and mass of the steel sheet also play a role in its soundproofing effectiveness.

- Q: What are the common thicknesses for roofing steel sheets?

- Roofing steel sheets come in a variety of thicknesses, typically ranging from 0.4mm to 0.8mm. Nevertheless, the actual thickness required will be influenced by factors like the roofing system type, regional climate, and desired durability level. In regions prone to harsh weather, thicker steel sheets, like those around 0.8mm, are commonly employed, whereas thinner sheets may suffice for less challenging environments. Consulting with a roofing expert or manufacturer is crucial to ascertain the ideal thickness for a particular roofing undertaking.

Send your message to us

Cold rolled steel sheet hot sale in alibaba china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 61450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords