Cold Rolled Sheet And Hot Rolled Sheet Cheapest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet and cold rawn sheet and hot drawn plate are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H14, H12,H22,H24,H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

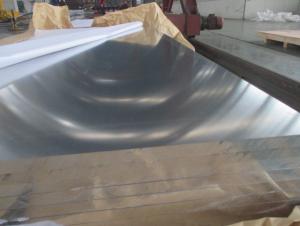

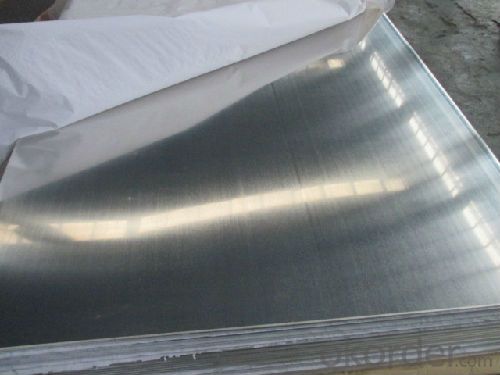

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm,1000*1000, 500mm*500mm,600mm*600mm,.

1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, Singapore, etc.

What is your mainly products?

---Normally they are aluminum sheet, checkered sheet, hot rolled sheet and cold rolled sheet,

mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: What is called anti fingerprint stainless steel sheet?

- Anti fingerprint (also known as non fingerprint) stainless steel plate is a protective layer treatment process is extremely thin and solid formed on the surface of stainless steel by nano coating technology, the stainless steel surface can not only achieve the anti fingerprint effect, but also can improve the ability of anti corrosion; and processing, such as bending or stamping processing can meet the general request.

- Q: Can stainless steel sheets be used in chemical processing plants?

- Yes, stainless steel sheets are commonly used in chemical processing plants due to their excellent corrosion resistance and high strength properties, making them suitable for handling various chemicals and harsh environments.

- Q: Inspection method for stainless steel welding

- 1) measurement, in strict accordance with the requirements of the drawings, and to ensure that within tolerance. Along the column, a top cover, and frame, beam should be straight, without distortion, the straightness (nonstraightness) should meet the requirements on the table diagonal method.2) no distortion, swing, rotation or displacement are allowed in the structures which are completely fixed

- Q: How do you cut stainless steel sheets?

- Different methods can be employed to cut stainless steel sheets, depending on the sheet's thickness and the desired level of precision. Here are several commonly used techniques: 1. Manual cutting: Thinner stainless steel sheets (up to approximately 16 gauge) can be cut using handheld shears or tin snips. These tools allow for straight or curved cuts by applying pressure and slicing through the sheet. However, this approach may not be suitable for thicker sheets due to its labor-intensive nature and the potential for producing rough edges. 2. Power shears: When dealing with thicker stainless steel sheets, power shears or electric nibblers prove more efficient. These tools employ a sharp cutting blade or punch to make straight or curved cuts. They offer greater precision and require less effort compared to manual cutting methods. 3. Circular saw: Stainless steel sheets of increased thickness can also be cut using a circular saw outfitted with a carbide-tipped blade specifically designed for metal cutting. This method allows for straight cuts but may generate more noise, sparks, and heat. Consequently, appropriate safety measures, such as wearing protective goggles and gloves, should be taken. 4. Plasma cutting: Plasma cutting is commonly utilized for industrial or heavy-duty applications. This technique involves employing a high-temperature plasma jet to melt through the stainless steel sheet, generating a precise and clean cut. However, plasma cutting machines are expensive and necessitate specialized training in operation. Irrespective of the chosen method, it is crucial to prioritize safety when cutting stainless steel sheets. Always wear protective gear, such as safety glasses, gloves, and a dust mask, to safeguard against metal shards, sparks, and dust. Moreover, ensure that the sheet is securely clamped or supported to prevent any movement during the cutting process.

- Q: Stainless steel plate laser cutting how to charge?

- It depends on which laser machine you use, and the specific model, and the processing materials are also different. Consumption is mainly: electricity, laser gas, auxiliary gas, consumables, general machine tool software has billing function, but not allowed.

- Q: What are the common sizes and thicknesses of stainless steel sheets?

- The sizes and thicknesses of stainless steel sheets vary depending on their intended use and industry standards. However, there are standard sizes and thicknesses commonly found in the market. Stainless steel sheets are commonly available in sizes ranging from 4x8 feet (1219x2438mm) to 5x10 feet (1524x3048mm). These sizes are widely used in construction, automotive, and fabrication applications. In terms of thickness, stainless steel sheets come in a range of gauges, typically measured in inches or millimeters. The most frequently used thicknesses are 0.0276 inches (0.7mm), 0.0359 inches (0.91mm), 0.0478 inches (1.21mm), 0.0598 inches (1.52mm), 0.0747 inches (1.90mm), and 0.0897 inches (2.28mm). These thicknesses find frequent application in commercial and industrial settings. It is important to note that stainless steel sheets can be customized to meet specific requirements, encompassing non-standard sizes and thicknesses. In such instances, it is advisable to seek guidance from a supplier or manufacturer who can offer tailored solutions based on the project's unique needs.

- Q: What are the different types of perforated patterns available for stainless steel sheets?

- There are several different types of perforated patterns available for stainless steel sheets, including round, square, slotted, and decorative patterns. Each pattern offers a unique aesthetic appeal and functional characteristics, making it suitable for various applications.

- Q: Can stainless steel sheets be used for fire escapes?

- Yes, stainless steel sheets can be used for fire escapes. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for fire escape applications. It can withstand high temperatures and is not easily affected by fire or heat, ensuring the safety and reliability of fire escapes.

- Q: What are the common manufacturing standards for stainless steel sheets?

- There are several common manufacturing standards for stainless steel sheets that ensure their quality and consistency. One of the most widely recognized standards is the ASTM International (formerly known as the American Society for Testing and Materials) standard. ASTM A240 is the specific standard for stainless steel sheets, which specifies the requirements for chemical composition, mechanical properties, and other relevant characteristics of the material. Another important manufacturing standard is the EN (European Norm) standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers various aspects such as dimensions, tolerances, surface finishes, and more. Additionally, there are national standards developed by different countries. For example, in Japan, the Japanese Industrial Standards (JIS) classify stainless steel sheets under various specifications such as JIS G4304 and JIS G4305. These standards define the requirements for chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) also sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in the manufacturing of stainless steel sheets, and their properties are defined by the AISI. It is important for manufacturers and suppliers to adhere to these standards to ensure that the stainless steel sheets meet the desired quality requirements and can be used reliably in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across different industries.

- Q: What is the area of stainless steel plate?

- First of all, I said, can not be sold by area, because the thickness of the price is not the same, I said the weight is how to draw, take SUS304 steel:Length (m) * width (mm) * thickness (mm) * density (7.93) /1000= weight

Send your message to us

Cold Rolled Sheet And Hot Rolled Sheet Cheapest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords