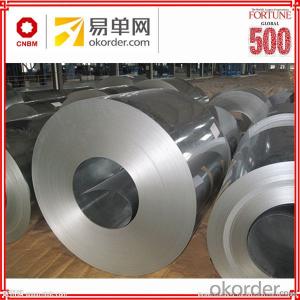

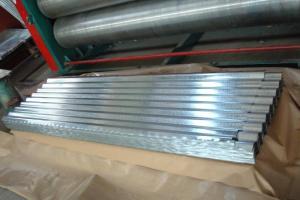

Cold rolled steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard export package or as required. |

| Delivery Detail: | 5-30 days or according to the quantity. |

Specifications

1.Length:as your requirement

2.Width: 40-1250mm

3.Thickness:0.18-2mm

4.Color:RAL No

- Q: why do you need to heat steel when hardening, molecules etc etc

- Gary is right, but maybe I can simplify it. It's very complex..... When you heat (hardenable) steel the carbon and iron form crystalline structures. Martensite and Austenite are most prominent, but there are others. Those are the hard crystals. When you quench it, those structures don't have time to dissolve as they would with slow cooling, so you freeze the crystalline structure in that state. Since that is too hard for most things, you temper it. Heating to a certain temp lets ~some~ of the crystals dissolve away. Annealing is heating and letting it cool slowly, so those structures will break up back into carbon and iron, leaving the steel soft. It's like a little atomic machine - crystals form, dissolve away, form again, with heat. It's waaaaay deeper than just that in detail, but that's the gist of it.

- Q: I was cutting a sheet of steel with an angle grinder when suddenly the rate at which the blade was cutting slowed way down. I tried a few different things, and turned off the tool and looked at the blade. It didn't look damaged, but it definitely was not cutting as quickly. I thought either I had hit a harder section of steel (is that possible? It looked pretty uniform) or the blade had lost it's abrasive quality or something. Also, before this happened I had accidentally cut into the wooden sawhorse that was holding up the steel sheet, but I've done that before with no problem. After a short while the problem fixed itself and the rate of cutting went back to a fast normal. Anyone know why this happened?

- Sounds like the abrasive surface got blinded, coated with something that prevented the abrasive particles from touching the steel. It is possible to have vastly different hardnesses in a single piece of steel. Case hardening, carburizing, induction hardening, heat affected zone from welding, differences in work hardening, and presence of inclusions are some of the things that can create hardness variation within a single piece. But... sounds like you are working with a sheet which is unlikely to have any of these conditions. So... it was probably the grinding disk

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its dimensions and thickness. However, on average, a steel coil can weigh anywhere between 2 to 20 tons.

- Q: How are steel coils protected during shipping?

- Steel coils are protected during shipping through a variety of measures to ensure their safety and prevent damage. One common method is the use of steel coil cradles or saddles. These are specially designed structures that hold the coils securely in place and prevent them from shifting or rolling during transit. The cradles are typically made of sturdy steel or other durable materials and are specifically engineered to withstand the weight and pressure of the coils. In addition to the cradles, steel coils are often wrapped in protective materials such as plastic or paper. This wrapping acts as a barrier, shielding the coils from moisture, dust, and other potential contaminants that could affect their quality. The wrapping is typically applied tightly to the coils, ensuring that it stays in place throughout the shipping process. To further safeguard the coils, they are often loaded into shipping containers or onto flatbed trucks using specialized equipment. This equipment, such as coil hooks or lifting clamps, allows for safe and secure handling of the coils, minimizing the risk of accidents or damage during loading and unloading. In some cases, steel coils may also be packed into wooden or metal crates for added protection. These crates provide an extra layer of security and help to prevent any potential impacts or rough handling from causing damage to the coils. Overall, the protection of steel coils during shipping is of utmost importance to ensure that they arrive at their destination in optimal condition. By utilizing cradles, protective wrapping, specialized equipment, and additional packaging when necessary, the risk of damage is significantly reduced, allowing for a smooth and successful transportation process.

- Q: How are steel coils used in the manufacturing of consumer goods?

- Steel coils are used in the manufacturing of consumer goods as a primary material for various applications. They are commonly used in the production of appliances, automotive parts, construction materials, and packaging materials. The coils can be shaped, cut, and formed into different components or structures, providing strength, durability, and versatility to the end products.

- Q: Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q: I have the game of the year edition for fallout 3 but there's no mission or quest saying it's called broken steel so what is it actually called and where is it? Please describe the quest in case I mightve already done it without even knowing.

- If I can remember right (SPOILER) you have to beat the game and instead of dying you just pass out and wake up with the brother hood of steel.

- Q: What is the lifespan of a steel coil?

- The lifespan of a steel coil can vary depending on various factors such as the quality of the steel, the conditions it is exposed to, and how well it is maintained. However, on average, steel coils can last anywhere from 10 to 30 years.

- Q: mass of steel ball=66.80 gramsdiameter of steel ball=2.51 cm

- The fact that they are pretty similar leads to the idea that Jupiter, too, is mostly H and He.

- Q: What are the challenges in coil edge trimming for narrow strips?

- There are several challenges in coil edge trimming for narrow strips. Firstly, one of the main challenges is maintaining accuracy and precision during the trimming process. Narrow strips require a high level of precision to ensure that the edges are trimmed evenly and smoothly. Any deviation from this precision can result in uneven edges or burrs, which can affect the overall quality of the strip. Secondly, there is the challenge of controlling the strip tension. Narrow strips are more prone to tension issues, as they have less surface area to distribute the tension evenly. This can lead to problems such as strip breakage or stretching, which can impact the final product's quality. Another challenge is avoiding material waste. Narrow strips often have a smaller margin for error, meaning that any mistakes in the trimming process can result in a significant amount of wasted material. Minimizing material waste is crucial for cost-effectiveness and sustainable manufacturing practices. Additionally, maintaining a high production rate can be challenging when working with narrow strips. The trimming equipment needs to be able to handle the high speed required for efficient production while still maintaining accuracy and precision. This requires the use of advanced machinery and technology to ensure smooth and efficient operations. Lastly, the handling and transportation of narrow strips can also pose challenges. Due to their small size, narrow strips are more susceptible to damage during handling and transportation. Proper care and handling techniques need to be implemented to prevent any potential damage, which could affect the quality of the final product. Overall, the challenges in coil edge trimming for narrow strips revolve around precision, tension control, material waste, production rate, and handling. Overcoming these challenges requires the use of advanced technology, skilled operators, and careful attention to detail throughout the entire process.

Send your message to us

Cold rolled steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords