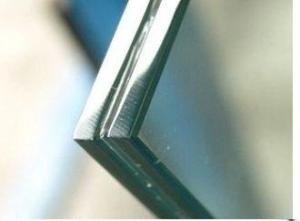

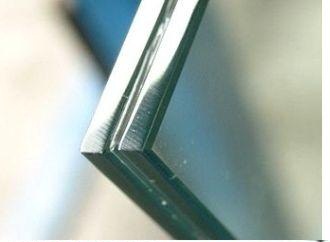

Coated laminated glass 8+1.14pvb+8+15A+8 curtain wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

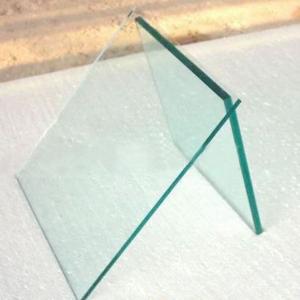

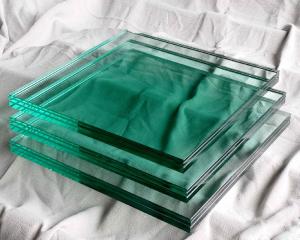

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: I see the vast majority of the glass curtain wall of the Dubai Hall of the building of the Chinese glass, there is a set of Zhengda always challenge Guinness inside a foreign rugby player does not break the Chinese glass. Why is the Chinese glass so good? Is the raw material good or technically good?

- Building glass production technology is the technical content is not very high mature technology, coupled with China's raw materials, relatively low wages of raw materials in recent years, China's curtain wall and construction contractors in foreign countries more and more so China's glass is really out of China Into the world!

- Q: Why is the glass transparent? What is extended is water, ice and so on transparent things Please explain from the principle, simply, you do not ask Glass reflected light and other objects reflect the light is nothing different, Why some objects can be transparent, and some objects are not transparent

- An important reason: a solid matter, if it is seen from the inside of the atom, it is actually empty. Because in the interior of the atom, the nuclei and the volume of electrons add up to less than one millionth of the atomic volume. Moreover, there is no evidence that the nucleus and electrons can not be photographed through! So, transparent is normal!

- Q: how is that relates to the glass which inhibit the characteristics of liquid?

- Glass is a liquid. Thus, it flows, just very very slowly. That means it will be thicker at the bottom, if mounted vertically, over a long period of time. After enough time has passed, the glass wont even be in the window anymore, it will have spilled downwards, just like spilling any other liquid. Just in extreme slow motion.

- Q: any home remedies to get the buildup on glasses off? i use jet dry and it's suppose to help but nothing does..it's nasty!

- You can soak them in white vinegar if indeed it is soap scum or hard water deposits. However, the answerer above is correct that if the glass is etched there is no way to remove it.

- Q: Hello, I would like to ask the frosted glass can be posted on the architectural glass film? Ask a lot of people but no sure answer

- Frosted glass matte surface film is not feasible, a short time may be no problem, a long time certainly a problem. Now has some professional film company to do frosted insulation film.

- Q: Tempered rubber safety glass thickness requirements?

- Film generally requires 1.14, if you use the glass thickness is relatively large like 10 +10,

- Q: Glass for building construction mainly.

- Ontario has 161 employers of Glass and Glass manufacturing

- Q: Is the laminated glass the same as the glass?

- Not the same effect laminated glass to be better but the cost of the above film plus cheap according to the actual conditions of choice

- Q: How to install architectural glass insulation film

- Hello: And paste the car membrane process is basically the same, if it is flat glass do not have a membrane, and first to clean the glass, and then cut the film, the film should be appropriate than the glass area, surrounded by extra, generally 5CM, and then removed Protective layer foil, first with a film spray on the glass film and clean the glass on the glass, and then foil, adjust the position after the hard scraping, soft scraping, tendon scraping.

Send your message to us

Coated laminated glass 8+1.14pvb+8+15A+8 curtain wall

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords