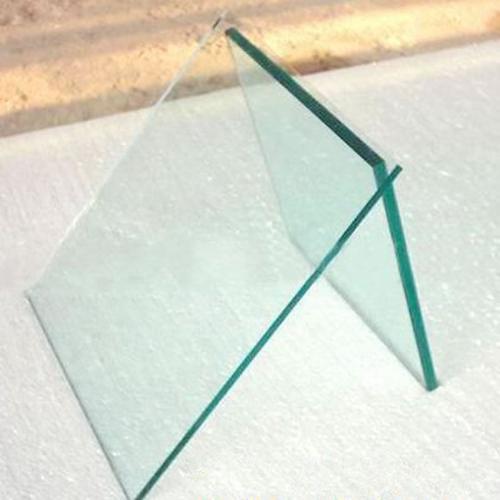

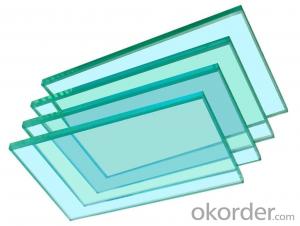

Clear Float Glass for Building, Mirror, Furnitures and Decoration Thickness 2mm-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Clear Float Glass for Building, Mirror, Furnitures and Decoration Thickness 2mm-19mm

● Characteristic

Smooth surface with no ripple, good perspectivity;

flexible specification to reduce slice loss;

glass with the thickness of 2-19mm and super-long super-large plate glass are available.

● Purpose

For buildings;

For mirrors;

For furniture and decoration;

For optical instrument;

For automobiles

● Thickness Range

2mm-19m

- Q: the usage of glass in building construction has been in constant increase in the past decade.these glasses would certainly increase the volume of reflection in the atmosphere..doesn't this add to the temperature rise ?

- A chalcogenide glass bolometer for detection of electromagnetic radiation wavelengths varying from infrared to microwave. The radiation absorbed by the glass increases its electrical conductivity, enabling measurement of the radiation. A method of fabricating the bolometer is also disclosed

- Q: Such as how many floors above the height, you must use more thick glass.

- Your problem "safety glass" related to "building safety glass management regulations", the glass thickness related to "technical requirements for the application of architectural glass" JGJ 113-2009

- Q: I am a listed glass production enterprises in the clerk, mainly to do the Dalian area of the construction of the glass market, as just doing this business, some touch the mind, do not know how to finally let Party to own glass brand Finalists, in fact, know that this side and Party A, Design Institute, as well as curtain wall construction side has a close contact, but for how to cut is not very clear, hope you master maze.

- Go to the site! Although the opportunity is slim, but do not take the first step how to run the relationship? Relationship is running out ah!

- Q: What is 5 + 12A + 5 transparent glass

- More commonly used called hollow glass, commonly used in residential real estate, villas, office buildings and other doors and windows curtain wall works of glass, with noise, heat insulation and other advantages.

- Q: Through the glass after the sun came in with the glass can not be compared to those who will be the skin of the sun more black ah? Seek experts

- So that the skin is black, is the sun in the ultraviolet. Ultraviolet rays are wavelengths shorter than visible light. The wavelength is between 390 and 400 nm. It can pass through the air, but it is not easy to pass through the glass, has the ability to sterilize, and has some damage to the eyes and skin.

- Q: Would you like to make windows white glass is good or green is good? That expensive Looks upscale? Thank you!

- Rewan glass: Rewan glass is heated by the plate glass to soften the mold in the mold, and then annealed by the curved glass. Rewan glass in some of the high-level decoration in the frequency of getting higher and higher, need to be scheduled, no cash.

- Q: Agc glass and Fuyao glass which is good

- Asahi Glass: English full name Asahi Glass, is a subsidiary of Japan's Mitsubishi. AGC Group is a more than 20 countries in the world with more than 350 branches, with more than 56,000 employees of multinational companies.

- Q: After you tell me the brand, could you tell me if you can buy it and Home Depot?If not available at Home Depot, where should you buy?

- What the heck is "nano"? Any pure silicone. Let set for 24 hours to cure. Preferably 1 week with water changes before fish can go in.

- Q: I saw some of them in the high-rise buildings on the glass window posted a film, which can see outside, outside can not see inside, what is the film? Are you expensive?

- Oh, ask them what paste the film chanting. A building are posted, and certainly have the effect will be such a ,,,,,

Send your message to us

Clear Float Glass for Building, Mirror, Furnitures and Decoration Thickness 2mm-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches