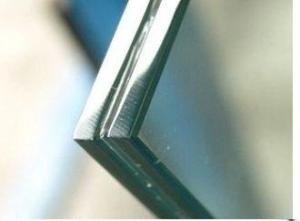

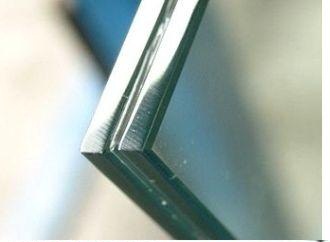

Coated laminated glass 8+1.52pvb+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: I'm building an aquarium. The size of my tank is going to be 8 feet by 3 feet with 5feet height. What is the better material to build an aquarium with (Glass or Acrylic)?

- Dan is the man and said it all! All my large tanks are super thick acrylic. They are lighter than glass, more durable, and hold in heat better.... No matter the material, it needs to be thick. Obviously 1/4 inch material of glass or acrylic is not going to hold LOL (all my acrylic tanks are over 1 inch thick and high quality acrylic)

- Q: Automotive glass insulation film paste technology

- The most basic tools are roasted guns, watering cans, foil special agent (or detergent water), water scraper, paste scraper, deerskin, Huju, a knife, each model is not the same paste method is not the same , But there is a common point of glass must be cleaned, preferably in the clean film between the operation.

- Q: I want to build a SMALL glass furnace. I'm not working with glass as a business or even as an artist (yet!!!) I want to teach myself to blow glass as a weekend hobby. I've researched the subject extensively and the more I do, the more I want to learn. Yes, I've looked into getting lessons from a professional in my area, it just isn't feasible for me.I can weld (several types), I'm good with electronics (both use and construction thereof) and I have access to all of the tools I could ever need and I can get parts as easy as that.Thank you so much.

- Lindsay okorder / You'll probably find more than you're looking for. It's an awesome resource.

- Q: How will the glass color fade

- The color of the vitreous itself is not faded because the color itself is through thousands of degrees of high temperature burned in the daily life of several temperature simply can not make it color. Our common architectural glass, red, blue, green, gold, are coated glass.

- Q: Is there a place that sells glass panels to be mounted together so you can build your own glass dome bedroom? I don't mind a 7-8 foot wall and then a dome on top.

- Yes okorder / you can ask with the details of your requirements. They answers promptly. Now you can complete your dream bedroom quickly. Wish one day I can visit your home to see it.

- Q: Is there a hmdso residue for the coated silica film?

- 1. Application in hard coatings: cutting tools, molds and wear-resistant corrosion-resistant parts. 2. In the protective coating applications: aircraft engine blades, automotive steel, heat sink and so on. 3. In the field of optical film applications: anti-reflective film, high anti-film, cut-off filter, anti-counterfeiting film. 4. Application in architectural glass: sunlight control film

- Q: VRAY rendering glass parameters how to tune?

- The setting parameters for clear glass and ground glass are different. clear glass: Diffuse: Gray (light gray) Reflex: 255 Refraction 255 Refractive index 1.2 ~ 1.5 can be, generally 1.5; Matte glass: Diffuse: gray (light gray) Reflex: 255 High light: 0.6 ~ 0.8 are glossy (high light): 0.9 Refraction: 255 Gloss (fuzzy): 0.9 Refractive index: 1.2 ~ 1.5 can be, general 1.5 After setting, you can take a small picture to see the approximate effect, and fine-tune according to the ambient light source.

- Q: Generally paste the glass insulation film is thick, there are several specifications ah? Is there anything that can be seen outside, and can not see inside the cellophane

- General insulation film is 1.2-1.5mil thickness, insulation film by reflection, blocking to heat. The so-called one-way perspective film is a kind of insulation film. Search for heat by reflection of the glass membrane.

- Q: Would like to ask Shaanxi master film industry architectural glass film / insulation film / decorative film how ah, no one has ever let them paste the film?

- I have not heard, but also seen it, the master in Shaanxi side with quite a lot, our department on the leadership and several colleagues at home are posted, and recently still posted, said the effect is good, and those who foil technology Very good, so all satisfied, the owner did not have to worry about the basic. You can consider their own, if you want to paste the words can be directly with them, people have specialized on-site service, directly to the solution, so that we themselves toss.

Send your message to us

Coated laminated glass 8+1.52pvb+8 Color glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords