Coated laminated glass 8+1.14pvb+8+15A+8 building glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

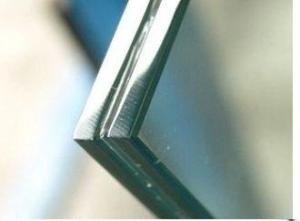

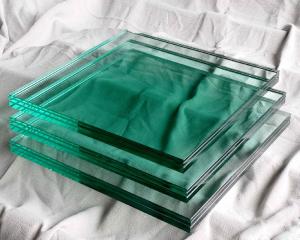

Laminated glass is processed via high temperature and high pressure after bonding with two layers or multiple layers of glass by polyvinyl butyral (PVB) film. Laminated glass which is produced with transparent film is similar with the ordinary annealed glass on appearance, but as a result, the toughness of PVB filmis very good, the film will quickly absorb a large number of impact energy when the laminated glass impacted by external forces, and make it attenuated. So, the laminated glass is hard to be breakdown, and as a result of the film adhesive ability, it will not fall off after the glass is broken, it can maintain an excellent integrity, there are still certain shielding performance, it can not only hurt the human body due to the scattered glass, but also there is enough time to replace glass. Therefore, laminated glass as a true sense of safety glass is widely used in building windows and doors, curtain wall, daylighting roof, skylight, ceiling and indoor glass partition, showcase, counters and other occasions.

Maximum processing size: 2500 mm * 8000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 6.38mm to 50 mm

Glass processing category: Flat laminated glass, curved laminated glass, colorful laminated glass.

Haiyang Shunda company introduced the super large laminated autoclaves, 13 meters long, high rate of using and output, well-distributed heating. The homogenization can be done within the autoclave, and equipped with reverse osmosis deionized water system and constant temperature, constant humidity, super clean production environment, make the production of product quality and service life guaranteed effectively.

Laminated glass

A. The selection of suitable float glass pane in storage

Access to the next process after the quality inspection of float glass

B. The measurements of glass to be cut as customized Access to the next stage after glass cutting quality inspection

Access to the next stage after glass cutting quality inspection

C. Perfect glass edge grinding

Access to the next stage after edge grinding quality inspection

D. Cleaning by deionized water

Access to the next stage after cleaning the glass

E. Tempered treatment,Bending tempered treatment

Access to the next stage after the quality inspectionof tempered glass

F. Cleaning by deionized water

Access to the next stage after cleaning the glass

G. Glass pressure in the constant temperature and humidity bioclean room

H. Heating and rolling

I. Inspection during the production process

J. Vacuumizing treatment in autoclave

Inspection during the production process

K. For subsequent processing and Packaging

L. Leading Time:10 days for an average area of 1000 square meters

tempered glass

M. Trade terms: FOB and CIF.

N. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

O. Loading and transport

- Q: What are the types and specifications of the glass? And how to identify the quality of the glass?

- General glass classification by material, such as: quartz glass, soda-lime glass, etc .; according to the thickness of the points, such as: 2mm5mm10mm, etc .; according to the use of points, such as: architectural glass, automotive glass, a variety of classification

- Q: Can architectural glass film be attached to a private car?

- Can be, and much better than the ordinary car to buy: Building film and car film are glass film, structure and application process is basically the same, have a safe, explosion-proof, heat insulation effect, if the market that we can interoperate, this is a consumer misunderstanding. The difference is that: 1, different glial: automotive film is a common adhesive (HPR) and the majority of the building film for the Qing Dynasty gum (CDF) and the safety film is used more adhesive paste, due to different nature, the car film The service life is about 3-5 years, while the building film is normally used for more than 20 years. 2, the metal content requirements are not the same, the volume of cadmium nickel and titanium can not exceed 5%, the building film can not exceed 2%, in this request only in line with the overall requirements of environmental protection, because the driving car is generally adults and healthy people, And people can not live long life in the car, and the building room, including pregnant women, babies and sick and sick people, rare metal radiation on the fetus, the baby's growth there is a certain impact, so the building film rare metal content can not exceed , Should follow the strict environmental protection standards. 3, car film and building film can be separated from ultraviolet light, but the absorption of UV layer structure is not the same, car film separated by ultraviolet layer, is a high-pressure coating a single layer, building film separated by ultraviolet layer is a vacuum sandwich, containing trace plutonium, Harmful spectrum, tuned spectrum video, car film only in the UV UA play a role in the building film UA and VB are working. 4, building film and car film thickness is not the same, the building insulation explosion-proof membrane is usually between 2mil-16mil, the general thickness of 2mil, 4mil, 4.5mil, 8mil, 9mil, 12mil, 14mil, 16mil and so on. Domestic thermal insulation film is usually only between 0.8mil - 1.5mil.

- Q: Sound insulation glass how much money a square

- Look at what kind of if it is about the insulating glass about 70 or so, if it is PVB folder glass prices about 130 up and down if the professional grade such as DEV glass price in the 400 to 500 yuan per square. Sound insulation glass produces the principle of sound insulation: a variety of outdoor sound source vibration generated noise, noise through the air. Media noise, when the noise is transmitted to the soundproof glass doors and windows, and then by the sound glass successive attenuation, especially after noise through the noise damping rubber, the frequency noise and high frequency noise is noise absorption damping rubber absorption, distortion, shock absorption, attenuation Will be in the high-frequency noise effectively filter out, and finally into the indoor noise is only about 5%. Usually the most common and most annoying most annoying people can not sleep "唿 唿", "嚯 嚯" in the high-frequency noise is basically no, but also heard, and the feeling of the room suddenly soft down, stay In the interior also more comfortable. Is the so-called: living in the downtown, the dream of the heart to achieve.

- Q: Used to make insulating glass for doors and windows or insulating glass or architectural glass!

- There is now a conductive glass, but not our common ordinary glass, but a new type of inorganic nonmetallic materials, such as: ITO conductive glass, is based on soda-lime or silicon-boron substrate glass, The method of sputtering is coated with a layer of indium tin oxide (commonly known as ITO) film processing made. LCD display dedicated.

- Q: GB / T16589 instead of which specification

- GB / T 28887-2017 Plastic window for construction is the first edition, so there is no substitute for other older versions. The specification refers to: GB / T 2680-1994 Building glass visible light transmittance, direct sunlight transmittance, solar total transmittance, UV transmittance and the determination of the relevant window parameters, GB / T 5823-2008 Building doors and windows terms, GB / T 7106-2008 Building exterior window windows airtight, watertight, wind pressure performance classification and testing methods, GB / T 8484-2008 building outside doors and windows insulation performance classification and testing methods, GB / T 8485-2008 building windows and doors air sound insulation (PVC-U) profiles, GB / T 11793-2008 Non-plasticized polyvinyl chloride (PVC-U) plastic doors and windows, mechanical properties, GB / T, And GB / T 11976-2002 GB / T 14436-1993 General rules for industrial product assurance documents, GB 50009 - 2001 (2006) JGJ / T 151-2008 Technical code for the application of architectural glass, JGJ / T 151-2008 Code for thermal calculation of glass curtain wall for building windows and doors, GB Building doors and windows.

- Q: Would you like to make windows white glass is good or green is good? That expensive Looks upscale? Thank you!

- Silk glass, also known as broken glass. Silk glass, also known as shatterproof glass, is the ordinary flat glass heated to red hot softening state, and then preheated wire or barbed wire into the middle of the glass and made. Clamp glass is characterized by superior fire resistance, can block the flame, high temperature combustion does not burst, broken will not cause debris wounding. In addition, there are anti-theft silk glass performance, glass cut and barbed wire barrier. Clamp glass is mainly used for roof skylights, balcony windows.

- Q: Pro, have to know this year 2.5 mm glass price (architectural glass)

- The price is not the same around, it is recommended that you go to the region cost information network price.

- Q: To a friend to say that under the sound of the glass how to choose it?

- Vacuum glass: because the vacuum glass between the two layers of glass was drawn into near vacuum, so with thermal resistance (Note 3) high characteristics, is a good insulation products, which is the original intention of the design of vacuum glass, with the insulation performance is hollow Glass is hard to compare. In the sound insulation performance of vacuum glass is also better than hollow glass.

- Q: Passing a shop, see a few characters "paste building film", not very understand this, would like to know about

- According to the classification of architectural glass foil: solar insulation film, safety explosion-proof film, interior decoration film. Function is different. Basically include the following features: ● function one, comfortable and energy saving, always enjoy - energy saving, adjust the indoor temperature, from the farewell air conditioning "burn" troubles. ● function two, to protect the building interior and occupants - blocking more than 99% harmful ultraviolet rays, to protect the health, to prevent furniture fade; outside the shelter line of sight, to create a private space; explosion shock, reduce accidental damage; build "stealth anti- Protect private property. ● function three, to improve the overall appearance of the building effect, build a harmonious office environment. ● function four, to reduce the nuisance glare - blocking the sun glare glare, to prevent light pollution, protect eyesight. ● function five, improve the efficiency of the staff - a variety of fancy, beautify the appearance of the room to improve the indoor environment. ● function six, explosion-proof, shock, reduce accidental injury, build "invisible anti-theft network" to protect private property. ● function seven, outdoor advertising industry gospel, to prevent glare, increase the perspective of click force, hinder the UV, to maintain the lasting and beautiful advertising.

Send your message to us

Coated laminated glass 8+1.14pvb+8+15A+8 building glass

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords