Aluminum Galvanized Sheets Cleveland - Coated Aluminum Sheet Coil for Roofing and Cladding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Specifications of Coated Aluminum Sheet Coil For Roofing And Cladding System

| Raw material | A1100/3003/3005/3105/8011 etc. |

| Certificate | ISO9001. ISO14001. SONCAP |

| Thickness | 0.02-3.0mm |

| Width | 1240mm |

| Color | As per RAL or your sample |

| Weight | 1.5-3MT/Coil |

2. Application of Coated Aluminum Sheet Coil For Roofing And Cladding System

Building, curtain wall, ceiling, panels, food packaging, condenser, air filter, refrigerators, washing machines, solar energy, automobile manufacturing, ship manufacturing, machinery manufacturing, electric equipment such as cosmetic packaging, machinery manufacturing industry, can also be used in power plants, chemical anti-corrosion insulation in petrochemical industry, etc.

3. Feature of Coated Aluminum Sheet Coil For Roofing And Cladding System

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

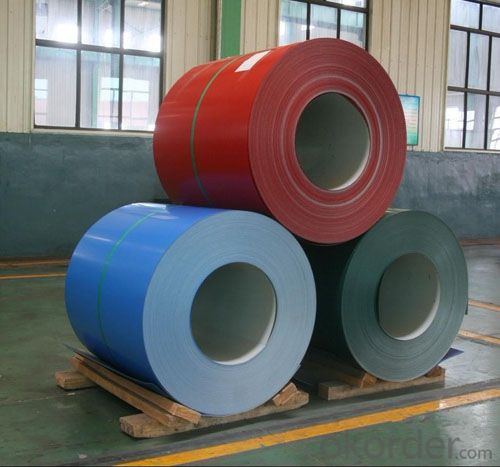

5. Image of Coated Aluminum Sheet Coil For Roofing And Cladding System

6. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP.

5) Could you offer sample?

We could offer sample as your requirement. A4 Size sample is free for you, for bigger roll sample, it depends on the coil weight.

- Q: why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- They both hurt a lot! Wooden ones are heavier and have more density, while aluminum ones are lighter, but they can swing a lot faster. So really, they both have their things about them that make them very painful. I wouldn't recommend getting smacked with ANY baseball bat - they HURT!!!

- Q: This question asks about the distinctions between aluminum sheets that are produced domestically versus those that are imported.

- <p>Yes, there can be differences between domestic and imported aluminum sheets. These differences may include quality standards, material composition, thickness, surface finish, and price. Domestic sheets are often produced to meet local standards and regulations, while imported sheets may adhere to different international standards. The manufacturing process and raw materials used can also vary, leading to differences in durability, strength, and workability. Additionally, imported sheets might have different certifications or come from countries with lower production costs, which can affect the price. However, it's important to note that not all imported aluminum sheets are of lower quality; some may be of higher quality or have specific characteristics that are not available domestically.</p>

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets have excellent water resistance properties. Due to the natural oxide layer that forms on its surface, aluminum is highly resistant to corrosion and effectively prevents the penetration of water. This oxide layer, also known as aluminum oxide, acts as a protective barrier, inhibiting the reaction between aluminum and water molecules. Additionally, aluminum sheets can be further enhanced with different surface treatments, such as anodizing or coating, to improve their water resistance even further. These treatments create a thicker and more durable oxide layer, making the aluminum sheets highly resistant to water damage, moisture, and rust. Overall, aluminum sheets are a reliable choice for applications that require water resistance, ensuring long-lasting performance in various environments.

- Q: Are aluminum sheets fire resistant?

- Yes, aluminum sheets are fire resistant.

- Q: What are the safety standards for aluminum sheets utilized in construction?

- <p>Yes, there are safety standards for aluminum sheets used in construction. These standards ensure the material's quality, strength, and suitability for various applications. They include specifications for thickness, alloy type, and surface treatment. International standards such as ASTM B209 (for aluminum sheet and plate) and EN 485 (for aluminum and aluminum alloy sheets) govern the production and use of aluminum sheets in construction. Compliance with these standards is crucial for safety, durability, and to meet regulatory requirements in different regions.</p>

- Q: Is aluminum sheet magnetic?

- Incorrect, aluminum sheets lack magnetic properties. As a non-magnetic metal, aluminum neither attracts nor repels magnetic materials due to the absence of magnetic elements within its composition. Consequently, attempting to affix a magnet onto an aluminum sheet will prove futile, as it remains unaffected by magnetic fields.

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight of 101 aluminum sheets per square foot may vary based on the thickness of the sheets. Typically, aluminum weight is measured in pounds per square foot (lbs/ft²). To accurately determine the weight per square foot of 101 aluminum sheets, it is necessary to be aware of the thickness of each individual sheet. Once the thickness is known, the weight per square foot can be calculated by utilizing the density of aluminum, which is approximately 0.098 pounds per cubic inch (lbs/in³).

- Q: project on aluminum and i cant think of a good/funny slogan for it! HELP! i have already seen the other possibilities on google, try to be unique, and creative! but if you cant just answer the flipping question PLZ!

- Aluminum: Keeping stoners amazed for over 50 years!

- Q: How much do aluminum sheets typically weigh?

- The weight of aluminum sheets ranges from 1.9 to 3.4 grams per square centimeter, and this varies depending on the sheet's thickness and size. Aluminum sheet weight can differ considerably based on its dimensions and gauge. Thinner sheets are typically lighter, while thicker ones tend to be heavier. It is worth mentioning that factors like the alloy utilized and any surface coatings or treatments can also impact the weight of aluminum sheets. Hence, it is recommended to refer to the product specifications or contact the manufacturer for precise weight details.

Send your message to us

Aluminum Galvanized Sheets Cleveland - Coated Aluminum Sheet Coil for Roofing and Cladding System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords